Vapor-grown carbon fiber offers superior tensile strength and electrical conductivity compared to electrospun carbon fiber, making it ideal for high-performance composite materials. Electrospun carbon fiber, characterized by its nanofibrous structure, provides excellent surface area and flexibility, enhancing applications in filtration and sensors. Choosing between these fibers depends on specific requirements such as mechanical durability or surface reactivity in carbon PET composites.

Table of Comparison

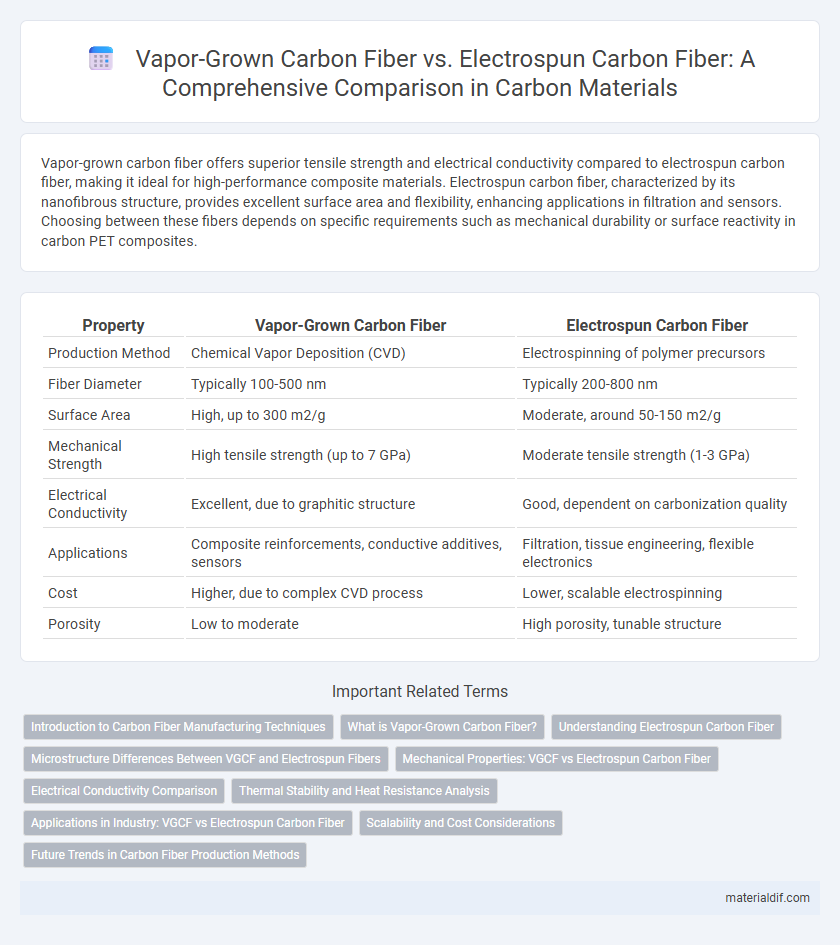

| Property | Vapor-Grown Carbon Fiber | Electrospun Carbon Fiber |

|---|---|---|

| Production Method | Chemical Vapor Deposition (CVD) | Electrospinning of polymer precursors |

| Fiber Diameter | Typically 100-500 nm | Typically 200-800 nm |

| Surface Area | High, up to 300 m2/g | Moderate, around 50-150 m2/g |

| Mechanical Strength | High tensile strength (up to 7 GPa) | Moderate tensile strength (1-3 GPa) |

| Electrical Conductivity | Excellent, due to graphitic structure | Good, dependent on carbonization quality |

| Applications | Composite reinforcements, conductive additives, sensors | Filtration, tissue engineering, flexible electronics |

| Cost | Higher, due to complex CVD process | Lower, scalable electrospinning |

| Porosity | Low to moderate | High porosity, tunable structure |

Introduction to Carbon Fiber Manufacturing Techniques

Vapor-grown carbon fiber (VGCF) and electrospun carbon fiber represent two advanced manufacturing techniques that significantly influence fiber morphology and performance. VGCF is produced through catalytic chemical vapor deposition, resulting in highly graphitized fibers with exceptional electrical conductivity and mechanical strength. Electrospinning fabricates ultra-fine carbon fibers by jetting polymer solutions that, after stabilization and carbonization, yield customizable fiber diameters and complex nanostructures essential for high-performance composite applications.

What is Vapor-Grown Carbon Fiber?

Vapor-grown carbon fiber (VGCF) is a type of carbon fiber synthesized through chemical vapor deposition (CVD), producing ultrafine, cylindrical fibers with diameters typically ranging from 100 to 200 nanometers. VGCF exhibits high electrical conductivity, excellent mechanical strength, and high aspect ratio, making it suitable for advanced composites, battery electrodes, and conductive fillers. Compared to electrospun carbon fiber, VGCF has more uniform morphology and enhanced crystallinity, contributing to superior performance in energy storage and structural applications.

Understanding Electrospun Carbon Fiber

Electrospun carbon fiber is produced by electrospinning a polymer precursor into ultrafine fibers, followed by stabilization and carbonization to achieve high carbon content and structural integrity. This method allows for precise control over fiber diameter, morphology, and surface area, resulting in materials with excellent mechanical properties and enhanced electrical conductivity. Compared to vapor-grown carbon fibers, electrospun fibers offer higher flexibility in functionalization and potential for tailored applications in energy storage, filtration, and composite materials.

Microstructure Differences Between VGCF and Electrospun Fibers

Vapor-grown carbon fibers (VGCF) exhibit a graphitic, tubular microstructure with a relatively uniform diameter and well-aligned graphene layers, enhancing electrical conductivity and mechanical strength. In contrast, electrospun carbon fibers possess a more amorphous, porous microstructure with a wider diameter distribution and randomly oriented carbon domains, which influences their surface area and flexibility. These microstructural differences significantly impact the performance characteristics of VGCF and electrospun fibers in applications like composite reinforcement and energy storage.

Mechanical Properties: VGCF vs Electrospun Carbon Fiber

Vapor-grown carbon fibers (VGCF) exhibit superior tensile strength and modulus compared to electrospun carbon fibers due to their highly crystalline graphitic structure and larger diameter. Electrospun carbon fibers, while offering finer fiber diameters and higher surface area, generally have lower mechanical stiffness and strength due to their less ordered microstructure. The mechanical performance of VGCF makes them more suitable for applications requiring enhanced load-bearing capabilities and structural reinforcement.

Electrical Conductivity Comparison

Vapor-grown carbon fiber (VGCF) exhibits higher electrical conductivity compared to electrospun carbon fiber due to its well-graphitized structure and fewer defects, enabling efficient electron transport along the fiber axis. Electrospun carbon fibers typically show lower conductivity because of their porous, less ordered carbon matrix and higher surface area, which introduce scattering sites and impede electron flow. VGCF's superior conductivity makes it more suitable for applications requiring enhanced electrical performance, such as electromagnetic interference shielding and battery electrodes.

Thermal Stability and Heat Resistance Analysis

Vapor-grown carbon fiber (VGCF) exhibits superior thermal stability and heat resistance compared to electrospun carbon fiber due to its higher graphitization degree and fewer structural defects. VGCF maintains mechanical integrity at temperatures exceeding 2500degC, whereas electrospun fibers typically degrade around 1500degC to 2000degC because of their amorphous carbon content. The enhanced crystalline structure of VGCF enables improved thermal conductivity and resistance to oxidation, making it ideal for high-temperature applications.

Applications in Industry: VGCF vs Electrospun Carbon Fiber

Vapor-grown carbon fiber (VGCF) offers high electrical conductivity and thermal stability, making it ideal for applications in aerospace and electronics, where enhanced mechanical strength and heat dissipation are crucial. Electrospun carbon fiber exhibits superior surface area and porosity, which is beneficial for energy storage devices like supercapacitors and batteries, as well as filtration systems. The choice between VGCF and electrospun carbon fiber depends on the specific industrial requirements for conductivity, mechanical properties, and surface morphology.

Scalability and Cost Considerations

Vapor-grown carbon fiber offers high scalability due to its continuous production process and lower raw material costs, making it suitable for large-scale industrial applications. Electrospun carbon fiber, while providing superior fiber morphology control, faces scalability challenges because of slower production rates and higher energy consumption. Cost considerations strongly favor vapor-grown carbon fiber for mass manufacturing, whereas electrospun fibers are typically reserved for specialized, high-performance applications where precision outweighs volume.

Future Trends in Carbon Fiber Production Methods

Advancements in vapor-grown carbon fiber emphasize enhanced structural integrity and conductive properties, targeting high-performance applications in aerospace and electronics. Electrospun carbon fibers increasingly gain attention for their tunable porosity and nanoscale diameter, ideal for energy storage and filtration technologies. Future trends revolve around integrating these methods to produce hybrid carbon fibers, optimizing both mechanical strength and functional versatility for next-generation materials.

Vapor-grown carbon fiber vs Electrospun carbon fiber Infographic

materialdif.com

materialdif.com