Carbon black consists of fine particles produced by the incomplete combustion of heavy petroleum products, characterized by high purity and uniform particle size, making it ideal for reinforcing rubber and manufacturing inks. Soot, formed from the incomplete combustion of organic materials, contains a mix of carbon particles and other substances such as hydrocarbons, resulting in a less uniform and more porous structure. The primary distinction lies in carbon black's controlled production process and consistent quality versus soot's heterogeneous composition and environmental pollutant classification.

Table of Comparison

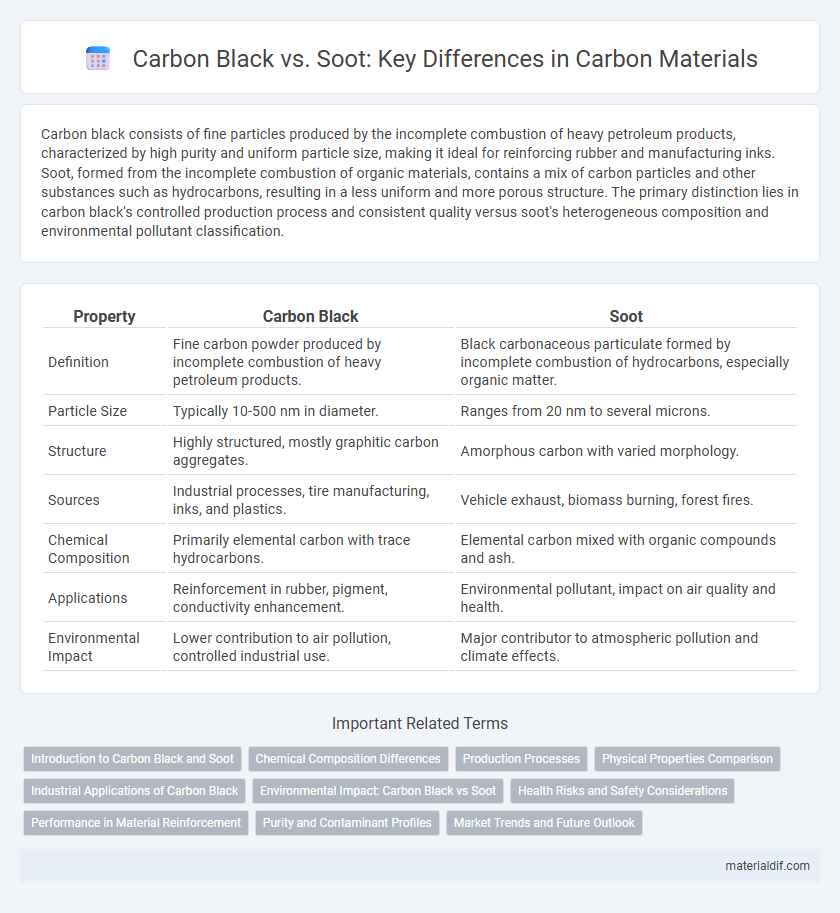

| Property | Carbon Black | Soot |

|---|---|---|

| Definition | Fine carbon powder produced by incomplete combustion of heavy petroleum products. | Black carbonaceous particulate formed by incomplete combustion of hydrocarbons, especially organic matter. |

| Particle Size | Typically 10-500 nm in diameter. | Ranges from 20 nm to several microns. |

| Structure | Highly structured, mostly graphitic carbon aggregates. | Amorphous carbon with varied morphology. |

| Sources | Industrial processes, tire manufacturing, inks, and plastics. | Vehicle exhaust, biomass burning, forest fires. |

| Chemical Composition | Primarily elemental carbon with trace hydrocarbons. | Elemental carbon mixed with organic compounds and ash. |

| Applications | Reinforcement in rubber, pigment, conductivity enhancement. | Environmental pollutant, impact on air quality and health. |

| Environmental Impact | Lower contribution to air pollution, controlled industrial use. | Major contributor to atmospheric pollution and climate effects. |

Introduction to Carbon Black and Soot

Carbon black is a fine, powdered form of elemental carbon produced by the incomplete combustion of heavy petroleum products, widely used as a reinforcing filler in rubber and pigments in inks and coatings. Soot consists of carbonaceous particles generated by the incomplete combustion of hydrocarbons, often found in air pollution as fine particulate matter. Both carbon black and soot share similarities in composition but differ significantly in structure, purity, and industrial applications.

Chemical Composition Differences

Carbon black primarily consists of nearly pure elemental carbon with a high surface area and minimal impurities, produced by the incomplete combustion of heavy petroleum products. Soot contains a mix of elemental carbon, organic compounds, and trace amounts of metals and ash, resulting from the incomplete combustion of hydrocarbons like wood, coal, or diesel fuel. The differences in chemical composition influence their physical properties, with carbon black being more uniform and refined, whereas soot has a heterogeneous structure with various contaminants.

Production Processes

Carbon black is produced through the incomplete combustion or thermal decomposition of hydrocarbons in controlled industrial processes such as the furnace black process, which yields fine, spherical particles with high surface area used in rubber reinforcement and pigments. Soot forms as an unintentional byproduct of incomplete combustion of organic matter, typically during biomass burning, fossil fuel combustion, or wildfires, resulting in irregular, amorphous carbon aggregates with varying particle size and composition. The controlled conditions in carbon black production lead to consistency and purity, whereas soot varies widely depending on combustion temperature, fuel type, and oxygen availability.

Physical Properties Comparison

Carbon black consists of tiny, highly structured particles with a high surface area, while soot is composed of larger, irregular aggregates with a more amorphous structure. Carbon black typically exhibits higher purity and uniform particle size distribution compared to soot, which contains diverse contaminants and variable morphology. The differing physical properties influence their respective applications, with carbon black favored for industrial uses like reinforcement in rubber, and soot often found as a byproduct of incomplete combustion.

Industrial Applications of Carbon Black

Carbon black is a highly engineered form of carbon with a fine particle size and controlled surface area, primarily used as a reinforcing filler in rubber products, especially tires, enhancing durability and wear resistance. Unlike soot, which is an unrefined byproduct of incomplete combustion with irregular particle sizes, carbon black undergoes precise manufacturing processes such as furnace black or thermal black methods to ensure consistency and performance in industrial applications. Its unique properties make it essential in producing pigments, plastics, inks, and coatings, contributing to improved mechanical strength, UV protection, and conductivity in various manufacturing sectors.

Environmental Impact: Carbon Black vs Soot

Carbon black, primarily used as a reinforcing agent in tires and pigments, has a more controlled particle size and is manufactured under regulated conditions, resulting in lower environmental emissions compared to soot. Soot, a byproduct of incomplete combustion from fossil fuels and biomass burning, contains a higher concentration of harmful polycyclic aromatic hydrocarbons (PAHs) and fine particulate matter, posing significant risks to air quality and human health. The environmental impact of soot is more severe due to its contribution to respiratory diseases, climate change via black carbon deposition on ice, and persistent air pollution in urban and rural areas.

Health Risks and Safety Considerations

Carbon black consists of fine carbon particles primarily used in industrial applications, whereas soot is an unburned carbon residue from incomplete combustion. Exposure to both substances poses significant health risks, including respiratory issues, cardiovascular problems, and potential carcinogenic effects due to inhalation of ultrafine particles. Safety considerations emphasize adequate ventilation, use of personal protective equipment (PPE), and rigorous monitoring of air quality to minimize hazardous exposure.

Performance in Material Reinforcement

Carbon black significantly enhances material reinforcement by providing superior dispersion and interaction within polymer matrices, resulting in improved tensile strength and abrasion resistance. Soot, often comprising larger and irregular carbon particles, generally offers lower reinforcement efficiency due to inefficient stress transfer and weaker bonding with the host material. The optimized nanoscale structure of carbon black facilitates better mechanical performance in composites compared to the amorphous, less uniform structure of soot.

Purity and Contaminant Profiles

Carbon black exhibits a higher purity level compared to soot, with fewer organic contaminants and trace metals, making it ideal for industrial applications requiring consistent quality. Soot comprises a heterogeneous mixture of carbon particles with significant amounts of hydrocarbons, ash, and metallic impurities due to incomplete combustion. The distinct contaminant profiles influence their performance, with carbon black offering superior structural integrity while soot contains variable impurities that limit its use in high-grade materials.

Market Trends and Future Outlook

Market trends reveal increasing demand for carbon black in industries such as automotive, rubber, and plastics due to its superior reinforcing properties and consistency compared to soot. Advanced manufacturing processes and environmental regulations are driving innovation and growth in carbon black production, while soot, often considered an undesirable byproduct, is gaining attention in niche applications like nanomaterial development. The future outlook for carbon black emphasizes sustainable production methods and expanded usage in high-performance materials, positioning it favorably against soot in commercial markets.

Carbon Black vs Soot Infographic

materialdif.com

materialdif.com