CVD carbon is produced through chemical vapor deposition, resulting in a dense, uniform structure with high purity and excellent thermal conductivity. Pyrolytic carbon forms via the thermal decomposition of hydrocarbons, creating a layered, anisotropic material known for its mechanical strength and biocompatibility. Both types of carbon find specialized applications, with CVD carbon preferred in electronics and pyrolytic carbon commonly used in biomedical implants.

Table of Comparison

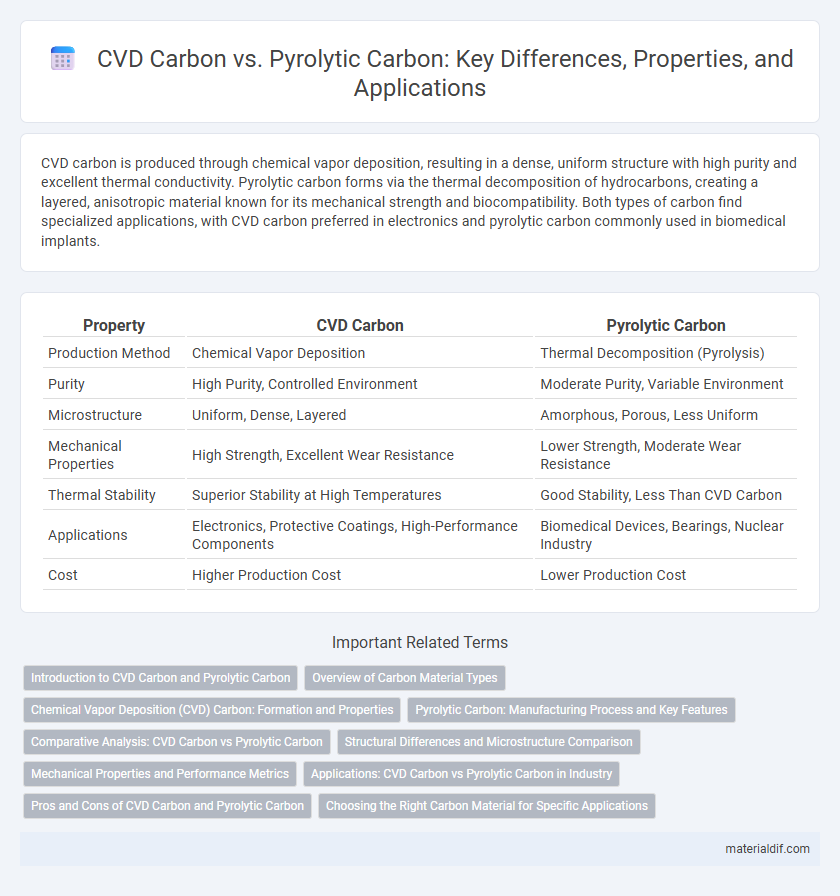

| Property | CVD Carbon | Pyrolytic Carbon |

|---|---|---|

| Production Method | Chemical Vapor Deposition | Thermal Decomposition (Pyrolysis) |

| Purity | High Purity, Controlled Environment | Moderate Purity, Variable Environment |

| Microstructure | Uniform, Dense, Layered | Amorphous, Porous, Less Uniform |

| Mechanical Properties | High Strength, Excellent Wear Resistance | Lower Strength, Moderate Wear Resistance |

| Thermal Stability | Superior Stability at High Temperatures | Good Stability, Less Than CVD Carbon |

| Applications | Electronics, Protective Coatings, High-Performance Components | Biomedical Devices, Bearings, Nuclear Industry |

| Cost | Higher Production Cost | Lower Production Cost |

Introduction to CVD Carbon and Pyrolytic Carbon

Chemical Vapor Deposition (CVD) carbon is formed by decomposing hydrocarbon gases at high temperatures, resulting in a highly pure, dense, and uniform carbon layer with excellent mechanical properties. Pyrolytic carbon is produced through the thermal decomposition of hydrocarbons in an inert atmosphere, characterized by its anisotropic structure and high strength, often used in biomedical and industrial applications. Both materials exhibit distinct structural and physical properties tailored by their deposition processes, influencing their performance in aerospace, electronics, and medical devices.

Overview of Carbon Material Types

Chemical Vapor Deposition (CVD) carbon features high purity and uniformity, produced by decomposing hydrocarbon gases on substrates at elevated temperatures. Pyrolytic carbon forms through the thermal decomposition of organic precursors under inert atmospheres, resulting in layered, anisotropic structures with excellent mechanical properties. Both materials are essential in applications requiring specific structural and chemical characteristics, such as biomedical implants and high-performance coatings.

Chemical Vapor Deposition (CVD) Carbon: Formation and Properties

Chemical Vapor Deposition (CVD) carbon forms through the decomposition of hydrocarbon gases at high temperatures, resulting in a uniform, dense carbon layer with controlled microstructure. This process yields carbon materials characterized by high purity, excellent mechanical strength, and enhanced thermal stability compared to pyrolytic carbon. The precise control of deposition parameters allows tunable properties, including high electrical conductivity and resistance to chemical corrosion, making CVD carbon ideal for advanced electronic and industrial applications.

Pyrolytic Carbon: Manufacturing Process and Key Features

Pyrolytic carbon is produced through a chemical vapor deposition (CVD) process involving the thermal decomposition of hydrocarbon gases at high temperatures, resulting in a dense, layered carbon structure. This material is characterized by exceptional biocompatibility, high strength, chemical inertness, and excellent wear resistance, making it suitable for biomedical implants such as heart valves. Unlike conventional CVD carbon, pyrolytic carbon exhibits anisotropic mechanical properties due to its graphitic basal plane alignment, enhancing its durability and performance under stress.

Comparative Analysis: CVD Carbon vs Pyrolytic Carbon

Chemical Vapor Deposition (CVD) carbon exhibits higher purity and superior structural uniformity compared to pyrolytic carbon, which is typically characterized by anisotropic grain structures and varying porosity. CVD carbon offers enhanced mechanical strength and thermal conductivity due to its controlled deposition process, while pyrolytic carbon is favored for its cost-effectiveness and ease of fabrication in biomedical and high-temperature applications. The selection between CVD and pyrolytic carbon depends on specific requirements such as electrical properties, surface morphology, and resistance to oxidation.

Structural Differences and Microstructure Comparison

CVD carbon exhibits a more uniform and fine-grained microstructure due to controlled chemical vapor deposition processes, resulting in excellent mechanical strength and higher purity. Pyrolytic carbon, formed through thermal decomposition of hydrocarbons, displays a layered, anisotropic structure with varying degrees of crystallinity and porosity. The structural differences between CVD and pyrolytic carbon directly influence their thermal conductivity, hardness, and defect density, impacting applications in aerospace and biomedical engineering.

Mechanical Properties and Performance Metrics

CVD carbon exhibits superior mechanical properties such as higher tensile strength and hardness compared to pyrolytic carbon, primarily due to its dense and uniform microstructure formed through chemical vapor deposition. Pyrolytic carbon, while offering excellent thermal stability and biocompatibility, generally shows lower mechanical strength and greater anisotropy, which can limit its performance under mechanical stress. Performance metrics highlight CVD carbon's enhanced wear resistance and fracture toughness, making it more suitable for high-stress applications in aerospace and electronics.

Applications: CVD Carbon vs Pyrolytic Carbon in Industry

CVD carbon is widely used in semiconductor manufacturing and high-performance coatings due to its uniformity and ability to form thin, conformal layers, making it ideal for microelectronics and protective applications. Pyrolytic carbon, with its high purity and exceptional biocompatibility, is commonly applied in medical implants, such as heart valves and orthopedic devices, as well as in nuclear reactors for its neutron absorption properties. Industrial applications of CVD carbon emphasize precision and thin-film coatings, while pyrolytic carbon dominates in roles requiring durability and resistance to extreme environments.

Pros and Cons of CVD Carbon and Pyrolytic Carbon

Chemical Vapor Deposition (CVD) carbon offers high purity and excellent mechanical strength, making it ideal for advanced electronic and coating applications, but its production is energy-intensive and costly. Pyrolytic carbon, produced through the thermal decomposition of hydrocarbons, provides superior biocompatibility and anisotropic properties suitable for medical implants, yet it has lower density and structural uniformity compared to CVD carbon. Both materials trade off between cost, structural quality, and application-specific performance, guiding the choice based on the required purity, mechanical properties, and economic feasibility.

Choosing the Right Carbon Material for Specific Applications

CVD carbon offers superior purity and uniformity ideal for electronic and coating applications demanding precise structural control, while pyrolytic carbon excels in high-temperature resistance and mechanical strength suited for biomedical implants and aerospace components. Selecting the right carbon material depends on application-specific requirements such as thermal conductivity, chemical stability, and surface morphology. Understanding the distinct synthesis methods and resultant microstructures informs optimal material choice, ensuring enhanced performance and durability in targeted industrial uses.

CVD carbon vs Pyrolytic carbon Infographic

materialdif.com

materialdif.com