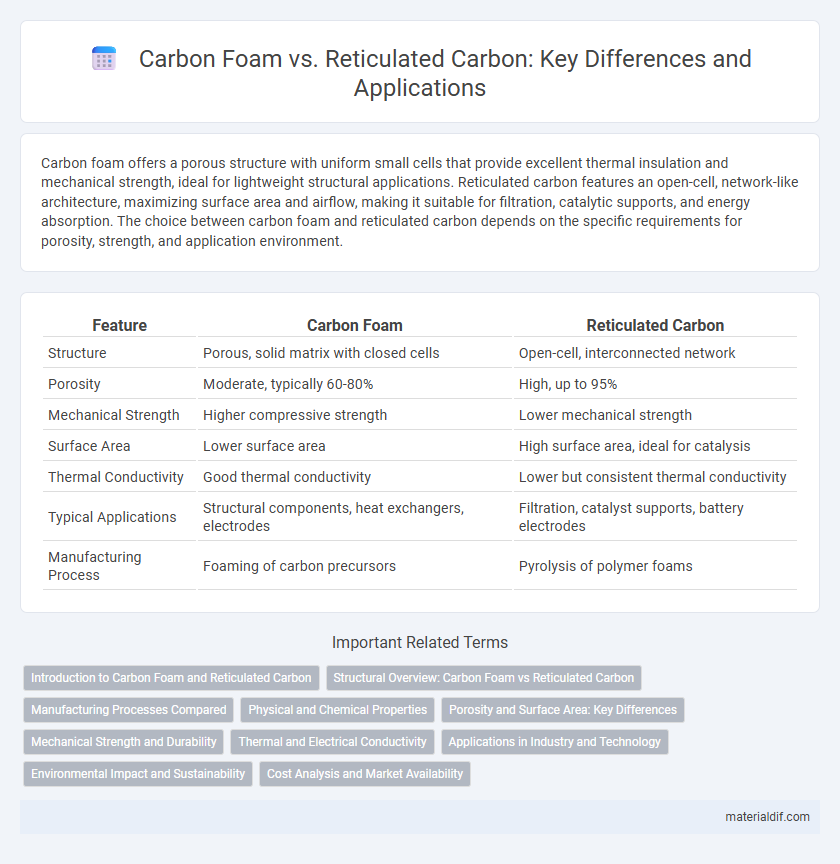

Carbon foam offers a porous structure with uniform small cells that provide excellent thermal insulation and mechanical strength, ideal for lightweight structural applications. Reticulated carbon features an open-cell, network-like architecture, maximizing surface area and airflow, making it suitable for filtration, catalytic supports, and energy absorption. The choice between carbon foam and reticulated carbon depends on the specific requirements for porosity, strength, and application environment.

Table of Comparison

| Feature | Carbon Foam | Reticulated Carbon |

|---|---|---|

| Structure | Porous, solid matrix with closed cells | Open-cell, interconnected network |

| Porosity | Moderate, typically 60-80% | High, up to 95% |

| Mechanical Strength | Higher compressive strength | Lower mechanical strength |

| Surface Area | Lower surface area | High surface area, ideal for catalysis |

| Thermal Conductivity | Good thermal conductivity | Lower but consistent thermal conductivity |

| Typical Applications | Structural components, heat exchangers, electrodes | Filtration, catalyst supports, battery electrodes |

| Manufacturing Process | Foaming of carbon precursors | Pyrolysis of polymer foams |

Introduction to Carbon Foam and Reticulated Carbon

Carbon foam features a porous, cellular structure with interconnected voids, offering high surface area and low density, making it ideal for lightweight thermal management and filtration applications. Reticulated carbon possesses an open-cell network created through a controlled reticulation process, resulting in uniform pore size and enhanced fluid permeability suited for catalyst supports and battery electrodes. Both materials leverage carbon's exceptional thermal conductivity and chemical stability, but their distinct morphologies cater to different industrial uses.

Structural Overview: Carbon Foam vs Reticulated Carbon

Carbon foam features a continuous matrix of interconnected pores providing high strength and thermal insulation, while reticulated carbon consists of a three-dimensional open-cell structure with a network of struts optimized for enhanced fluid flow and surface area. The closed-pore structure of carbon foam grants superior compressive strength and energy absorption, contrasting with the highly porous reticulated carbon that excels in filtration and catalytic support. Both materials possess unique microstructures tailored to specific engineering applications requiring lightweight durability and efficient gas or liquid permeability.

Manufacturing Processes Compared

Carbon foam is manufactured through a polymeric or metal precursor that undergoes pyrolysis, resulting in a rigid, porous structure with closed cells providing high strength and thermal insulation. Reticulated carbon, created by coating a polyurethane foam template with a carbon precursor followed by pyrolysis, features an open-cell structure with interconnected pores ideal for filtration and catalysis. The key manufacturing difference lies in the template-based approach for reticulated carbon versus direct foaming and carbonization in carbon foam, influencing their porosity, mechanical properties, and applications.

Physical and Chemical Properties

Carbon foam exhibits a porous, rigid structure with high thermal resistance and low density, making it ideal for insulation and energy absorption applications. Reticulated carbon features an open-cell network with interconnected pores, enabling superior fluid flow and catalytic surface area for filtration and electrochemical processes. Both materials demonstrate excellent chemical stability and electrical conductivity, but reticulated carbon's enhanced surface area supports greater catalytic activity compared to the more mechanically robust carbon foam.

Porosity and Surface Area: Key Differences

Carbon foam features high porosity with a structure composed of interconnected cells, providing moderate surface area ideal for thermal insulation and lightweight applications. Reticulated carbon, characterized by its open-pore network with minimal struts, exhibits exceptionally high surface area that enhances adsorption and catalytic properties. The key difference lies in porosity architecture: carbon foam emphasizes closed-cell porosity while reticulated carbon maximizes open porosity for surface-driven reactions.

Mechanical Strength and Durability

Carbon foam exhibits superior mechanical strength due to its dense, closed-cell structure that provides high compressive resistance and impact absorption. Reticulated carbon, characterized by its open-cell porous network, offers enhanced durability in cyclic applications through excellent energy dissipation but lower compressive strength compared to carbon foam. The choice between carbon foam and reticulated carbon depends on specific mechanical load requirements and longevity under operational stress.

Thermal and Electrical Conductivity

Carbon foam exhibits lower thermal conductivity compared to reticulated carbon, due to its closed-cell structure that limits heat transfer. Reticulated carbon offers superior electrical conductivity because of its interconnected porous network, enhancing electron flow across the material. Both materials find specialized applications where specific thermal and electrical conductivity properties are critical, such as in heat exchangers and electrode designs.

Applications in Industry and Technology

Carbon foam offers excellent thermal insulation and high strength-to-weight ratio, making it ideal for aerospace and automotive applications requiring heat resistance and structural support. Reticulated carbon, with its open-cell structure and high surface area, excels in filtration, catalysis, and energy storage technologies such as fuel cells and batteries. Industries leverage carbon foam for lightweight heat shields while utilizing reticulated carbon in environmental cleanup and gas storage systems due to its superior permeability and adsorption properties.

Environmental Impact and Sustainability

Carbon foam and reticulated carbon differ significantly in environmental impact and sustainability, with carbon foam offering higher energy efficiency in production due to its closed-cell structure that reduces raw material waste. Reticulated carbon, characterized by an open-cell porous matrix, supports enhanced recyclability and biodegradability, aligning with sustainable waste management practices. Both materials contribute to reducing carbon footprints, but reticulated carbon's superior environmental adaptability makes it preferable for eco-conscious applications.

Cost Analysis and Market Availability

Carbon foam typically offers lower production costs compared to reticulated carbon due to simpler manufacturing processes and raw material efficiency. Reticulated carbon, with its highly porous structure, commands a premium price driven by advanced fabrication techniques and superior performance in filtration and catalyst support applications. Market availability favors carbon foam for large-scale industrial uses, while reticulated carbon remains niche, primarily sourced from specialized suppliers targeting high-tech industries.

Carbon foam vs Reticulated carbon Infographic

materialdif.com

materialdif.com