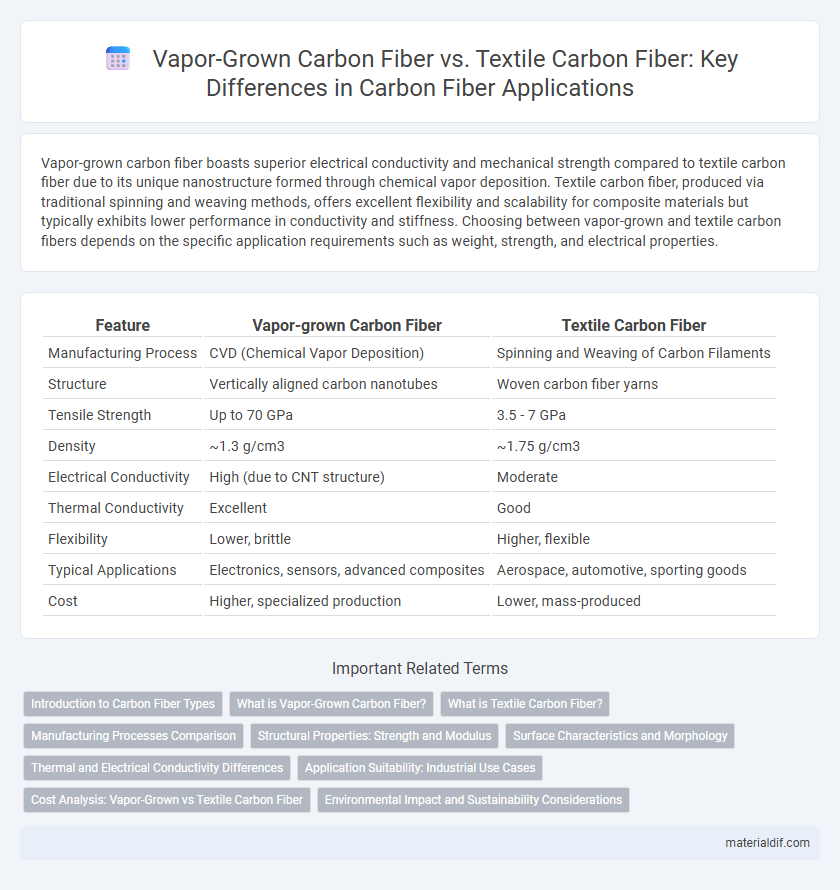

Vapor-grown carbon fiber boasts superior electrical conductivity and mechanical strength compared to textile carbon fiber due to its unique nanostructure formed through chemical vapor deposition. Textile carbon fiber, produced via traditional spinning and weaving methods, offers excellent flexibility and scalability for composite materials but typically exhibits lower performance in conductivity and stiffness. Choosing between vapor-grown and textile carbon fibers depends on the specific application requirements such as weight, strength, and electrical properties.

Table of Comparison

| Feature | Vapor-grown Carbon Fiber | Textile Carbon Fiber |

|---|---|---|

| Manufacturing Process | CVD (Chemical Vapor Deposition) | Spinning and Weaving of Carbon Filaments |

| Structure | Vertically aligned carbon nanotubes | Woven carbon fiber yarns |

| Tensile Strength | Up to 70 GPa | 3.5 - 7 GPa |

| Density | ~1.3 g/cm3 | ~1.75 g/cm3 |

| Electrical Conductivity | High (due to CNT structure) | Moderate |

| Thermal Conductivity | Excellent | Good |

| Flexibility | Lower, brittle | Higher, flexible |

| Typical Applications | Electronics, sensors, advanced composites | Aerospace, automotive, sporting goods |

| Cost | Higher, specialized production | Lower, mass-produced |

Introduction to Carbon Fiber Types

Vapor-grown carbon fiber is produced through chemical vapor deposition, yielding fibers with high surface area and excellent electrical conductivity, ideal for composite materials in aerospace and electronics. Textile carbon fiber derives from polyacrylonitrile (PAN) or pitch-based precursors, known for superior tensile strength and flexibility, commonly used in automotive and sporting goods industries. Each carbon fiber type offers distinct structural and functional properties tailored to specific engineering applications.

What is Vapor-Grown Carbon Fiber?

Vapor-grown carbon fiber (VGCF) is produced through a chemical vapor deposition process, resulting in ultra-fine carbon filaments with a high aspect ratio and excellent electrical conductivity. Unlike textile carbon fibers, which are spun and woven from polyacrylonitrile (PAN) or pitch-based precursors, VGCF offers superior surface area and strength-to-weight ratios, making it ideal for advanced composites and energy storage applications. The nanoscale diameter and graphitic structure of VGCF enhance mechanical reinforcement and electrical properties beyond traditional textile carbon fibers.

What is Textile Carbon Fiber?

Textile carbon fiber is produced by weaving carbon filaments into fabric form, creating flexible and lightweight materials ideal for composite manufacturing. Unlike vapor-grown carbon fiber, which is synthesized through chemical vapor deposition resulting in short, high-strength fibers, textile carbon fiber offers enhanced drapability and versatility in design applications. This material is widely used in aerospace, automotive, and sporting goods industries due to its excellent strength-to-weight ratio and ease of integration into complex shapes.

Manufacturing Processes Comparison

Vapor-grown carbon fiber is produced through chemical vapor deposition, where carbon atoms assemble on a substrate into fine, high-purity fibers, resulting in exceptional tensile strength and conductivity. Textile carbon fiber, manufactured via polyacrylonitrile (PAN) or pitch precursor spinning followed by stabilization and carbonization, offers greater flexibility and easier fabric formation for composite applications. The distinct manufacturing processes influence fiber morphology and performance, making vapor-grown fibers ideal for electronic components and textile fibers preferred in aerospace and automotive composites.

Structural Properties: Strength and Modulus

Vapor-grown carbon fiber exhibits superior tensile strength and higher modulus due to its well-aligned graphene layers, which enhance load transfer efficiency. Textile carbon fibers, while offering good flexibility and ease of fabrication, generally possess lower strength and modulus as a result of their woven structure and less uniform carbon orientation. These structural properties make vapor-grown carbon fibers ideal for high-performance applications requiring maximum stiffness and strength.

Surface Characteristics and Morphology

Vapor-grown carbon fiber exhibits a rougher surface texture and higher surface area due to its nanostructured morphology, enhancing interfacial bonding in composites compared to textile carbon fiber. Textile carbon fibers possess smoother surfaces with aligned graphitic layers, contributing to superior tensile strength and stiffness but limiting matrix adhesion. The distinct morphology of vapor-grown carbon fibers, characterized by entangled nanotubes, offers improved electrical conductivity and mechanical interlocking in composite materials.

Thermal and Electrical Conductivity Differences

Vapor-grown carbon fibers exhibit superior electrical conductivity compared to textile carbon fibers due to their highly graphitized microstructure, enhancing electron mobility. In contrast, textile carbon fibers, derived from polymer precursors through controlled pyrolysis, generally offer lower thermal conductivity but greater mechanical flexibility. These differences make vapor-grown carbon fibers ideal for applications requiring efficient heat dissipation and electrical conduction, while textile carbon fibers are preferred in composites needing structural versatility.

Application Suitability: Industrial Use Cases

Vapor-grown carbon fibers exhibit superior electrical conductivity and high surface area, making them ideal for advanced industrial applications such as battery electrodes, conductive composites, and electromagnetic interference shielding. Textile carbon fibers, known for their flexibility and weaving ability, are better suited for structural components in aerospace, automotive, and sports equipment where mechanical strength and lightweight properties are critical. The choice between vapor-grown and textile carbon fibers depends on specific application requirements like conductivity, mechanical performance, and manufacturing complexity.

Cost Analysis: Vapor-Grown vs Textile Carbon Fiber

Vapor-grown carbon fiber generally incurs higher production costs due to its complex synthesis process involving chemical vapor deposition, which demands specialized equipment and energy consumption. Textile carbon fiber, produced through conventional spinning and carbonization of polyacrylonitrile (PAN) or pitch-based precursors, benefits from established manufacturing techniques that reduce overall expenses. Cost analysis indicates textile carbon fiber remains more economically viable for large-scale applications, while vapor-grown carbon fiber, despite higher costs, offers superior mechanical properties valuable in niche, high-performance markets.

Environmental Impact and Sustainability Considerations

Vapor-grown carbon fibers (VGCF) demonstrate a higher energy consumption during production compared to textile carbon fibers, due to the chemical vapor deposition process requiring elevated temperatures and specialized equipment. Textile carbon fibers, derived from precursor fibers like PAN or rayon through carbonization, generally have a lower environmental footprint, particularly when sourced from bio-based or recycled materials. Sustainability considerations favor textile carbon fibers for scalable, eco-friendly manufacturing, whereas VGCF offers superior electrical conductivity at the expense of greater environmental impact.

Vapor-grown carbon fiber vs Textile carbon fiber Infographic

materialdif.com

materialdif.com