3K carbon features 3,000 filaments per tow, offering a smoother surface finish and greater flexibility, making it ideal for lightweight applications like cycling and drones. In contrast, 12K carbon consists of 12,000 filaments per tow, providing enhanced strength and stiffness while being heavier and less flexible, suitable for automotive and aerospace components. Choosing between 3K and 12K carbon depends on the balance needed between performance, weight, and durability in the specific project.

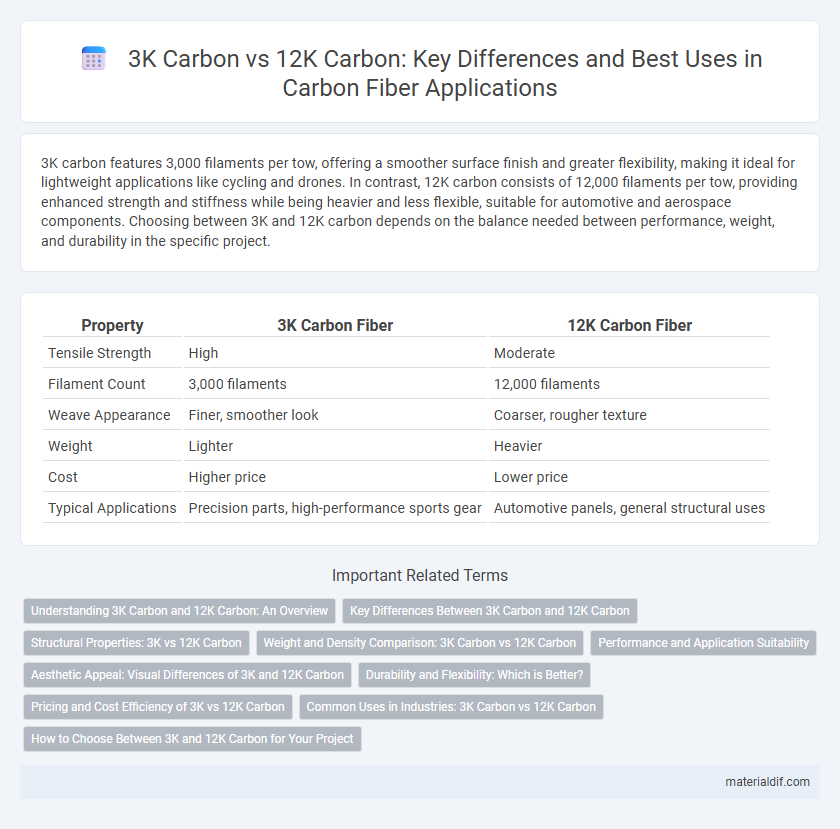

Table of Comparison

| Property | 3K Carbon Fiber | 12K Carbon Fiber |

|---|---|---|

| Tensile Strength | High | Moderate |

| Filament Count | 3,000 filaments | 12,000 filaments |

| Weave Appearance | Finer, smoother look | Coarser, rougher texture |

| Weight | Lighter | Heavier |

| Cost | Higher price | Lower price |

| Typical Applications | Precision parts, high-performance sports gear | Automotive panels, general structural uses |

Understanding 3K Carbon and 12K Carbon: An Overview

3K carbon fibers consist of 3,000 filaments per tow, offering higher flexibility and ease of handling, making them ideal for detailed and lightweight applications. In contrast, 12K carbon fibers contain 12,000 filaments per tow, providing increased strength and stiffness suitable for large-scale structural components. Selecting between 3K and 12K carbon depends on the specific performance requirements and manufacturing processes of the composite material.

Key Differences Between 3K Carbon and 12K Carbon

3K carbon fiber consists of 3,000 filaments per tow, resulting in a lighter and more flexible material ideal for applications requiring precision and fine detail. In contrast, 12K carbon fiber contains 12,000 filaments per tow, providing greater strength, stiffness, and efficiency for larger structural components. The increased filament count in 12K carbon enhances load-bearing capacity while making the material heavier and less pliable compared to 3K carbon fiber.

Structural Properties: 3K vs 12K Carbon

3K carbon fiber consists of approximately 3,000 filaments per tow, resulting in a lighter and more flexible material with excellent tensile strength and impact resistance, making it ideal for applications requiring high durability and precision. In comparison, 12K carbon fiber contains around 12,000 filaments per tow, offering greater stiffness and higher modulus but increased weight, which enhances structural rigidity for load-bearing components in aerospace and automotive industries. The choice between 3K and 12K carbon fibers depends on balancing the need for flexibility, strength, and rigidity in composite structures.

Weight and Density Comparison: 3K Carbon vs 12K Carbon

3K carbon fiber consists of 3,000 filaments per tow, making it lighter and more flexible compared to 12K carbon fiber, which contains 12,000 filaments per tow and is significantly denser and heavier. The higher filament count in 12K carbon increases its tensile strength and stiffness but also adds to the overall weight, making it ideal for applications requiring greater structural support. Engineers often choose 3K carbon for lightweight projects demanding flexibility, while 12K carbon suits heavier-duty uses where enhanced durability and strength are critical.

Performance and Application Suitability

3K carbon fiber features approximately 3,000 filaments per tow, offering a balance of strength, flexibility, and lightweight properties ideal for automotive components, sporting goods, and aerospace applications requiring high performance with moderate cost. In contrast, 12K carbon fiber contains around 12,000 filaments per tow, providing superior stiffness and strength suitable for large structural parts like wind turbine blades, aircraft fuselages, and high-end racing equipment where maximum durability and rigidity are critical. Selecting between 3K and 12K carbon fibers depends on the specific performance requirements and budget constraints, with 3K preferred for precision and flexibility, while 12K excels in heavy-duty, load-bearing scenarios.

Aesthetic Appeal: Visual Differences of 3K and 12K Carbon

3K carbon fiber features a distinctive twill weave pattern with 3,000 filaments per tow, creating a finer, more detailed visual texture favored for its classic look in automotive and sporting goods. In contrast, 12K carbon fiber consists of 12,000 filaments per tow, resulting in a broader, more uniform appearance that offers a sleek, modern aesthetic ideal for larger surfaces and contemporary designs. The choice between 3K and 12K carbon significantly impacts the visual complexity and luxury perception of finished products.

Durability and Flexibility: Which is Better?

3K carbon fiber features 3,000 filaments per tow, offering superior flexibility and ease of shaping, making it ideal for applications requiring intricate design and lightweight rigidity. In contrast, 12K carbon fiber with 12,000 filaments per tow provides enhanced durability and strength, suitable for high-stress environments and structural components needing maximum load-bearing capacity. Selecting between 3K and 12K carbon depends on balancing the need for flexibility versus durability in specific performance-driven applications.

Pricing and Cost Efficiency of 3K vs 12K Carbon

3K carbon fibers, featuring approximately 3,000 filaments per tow, are generally more cost-effective than 12K carbon fibers, which contain 12,000 filaments per tow, due to lower raw material and manufacturing expenses. 3K carbon offers superior cost efficiency for applications requiring high precision and surface finish, making it ideal for aerospace and automotive industries where weight and strength are critical. Despite the higher volume of fiber in 12K carbon, 3K carbon's finer filaments provide better handling and bonding properties, optimizing overall performance-cost balance.

Common Uses in Industries: 3K Carbon vs 12K Carbon

3K carbon fibers consist of 3,000 filaments per tow, making them ideal for applications requiring lightweight strength and flexibility, such as aerospace components, sporting goods, and automotive parts. In contrast, 12K carbon fibers, containing 12,000 filaments per tow, are preferred in industries demanding higher structural strength and durability, including wind turbine blades, automotive chassis, and heavy machinery. Both types offer excellent tensile strength and stiffness, but 3K fibers excel in precision and surface finish, while 12K fibers provide enhanced load-bearing capacity.

How to Choose Between 3K and 12K Carbon for Your Project

Choosing between 3K and 12K carbon fibers depends on the balance between weight, strength, and surface finish required for your project. 3K carbon fiber offers a finer weave with approximately 3,000 filaments per tow, ideal for lightweight applications demanding high-quality aesthetics and flexibility. In contrast, 12K carbon fiber contains around 12,000 filaments per tow, providing greater strength and stiffness for structural components but resulting in a coarser texture and heavier material.

3K Carbon vs 12K Carbon Infographic

materialdif.com

materialdif.com