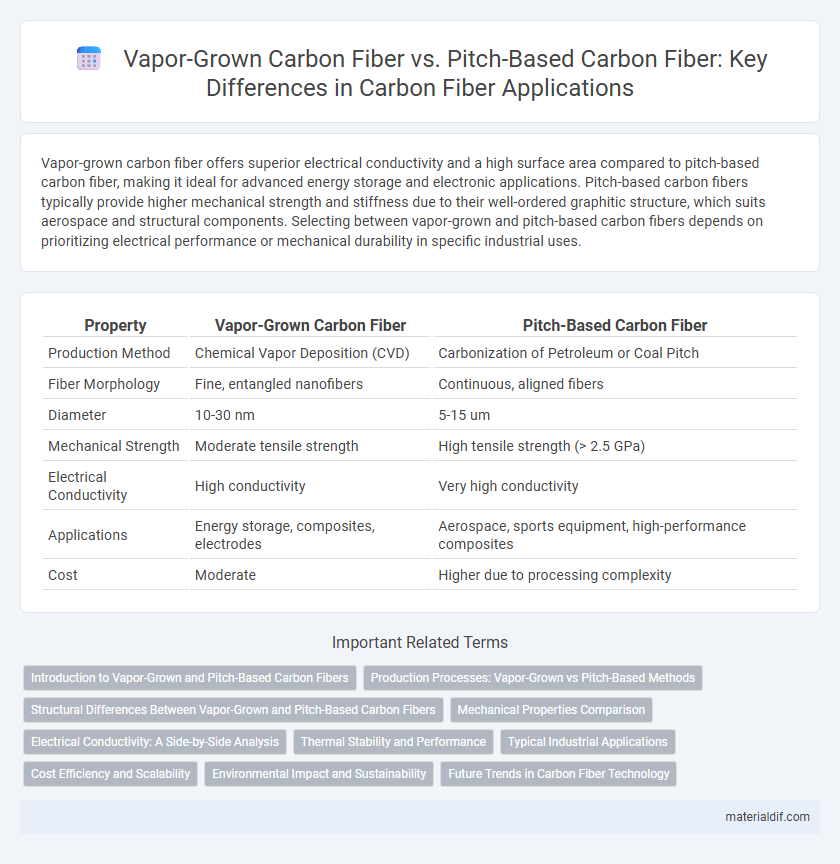

Vapor-grown carbon fiber offers superior electrical conductivity and a high surface area compared to pitch-based carbon fiber, making it ideal for advanced energy storage and electronic applications. Pitch-based carbon fibers typically provide higher mechanical strength and stiffness due to their well-ordered graphitic structure, which suits aerospace and structural components. Selecting between vapor-grown and pitch-based carbon fibers depends on prioritizing electrical performance or mechanical durability in specific industrial uses.

Table of Comparison

| Property | Vapor-Grown Carbon Fiber | Pitch-Based Carbon Fiber |

|---|---|---|

| Production Method | Chemical Vapor Deposition (CVD) | Carbonization of Petroleum or Coal Pitch |

| Fiber Morphology | Fine, entangled nanofibers | Continuous, aligned fibers |

| Diameter | 10-30 nm | 5-15 um |

| Mechanical Strength | Moderate tensile strength | High tensile strength (> 2.5 GPa) |

| Electrical Conductivity | High conductivity | Very high conductivity |

| Applications | Energy storage, composites, electrodes | Aerospace, sports equipment, high-performance composites |

| Cost | Moderate | Higher due to processing complexity |

Introduction to Vapor-Grown and Pitch-Based Carbon Fibers

Vapor-grown carbon fibers (VGCF) are produced through chemical vapor deposition, resulting in fibers with high surface area and excellent electrical conductivity, ideal for composite reinforcement and conductive materials. Pitch-based carbon fibers derive from isotropic or mesophase pitch with a higher graphitic structure, offering superior mechanical properties like high modulus and thermal stability, extensively used in aerospace applications. The distinct manufacturing processes and microstructures of VGCF and pitch-based fibers define their tailored performance in advanced material applications.

Production Processes: Vapor-Grown vs Pitch-Based Methods

Vapor-grown carbon fiber production involves the chemical vapor deposition (CVD) process, where hydrocarbons decompose on a substrate to form high-purity carbon fibers with controlled microstructure. Pitch-based carbon fiber production starts from carbon-rich pitch materials subjected to melt-spinning, stabilization, carbonization, and graphitization steps, yielding fibers with high modulus and thermal conductivity. The vapor-grown method offers superior control over fiber diameter and surface area, while pitch-based methods enable tailoring fiber properties through heat treatment parameters.

Structural Differences Between Vapor-Grown and Pitch-Based Carbon Fibers

Vapor-grown carbon fibers (VGCF) exhibit a fine, entangled network structure with a high aspect ratio, resulting in superior electrical conductivity and enhanced mechanical reinforcement in composites. In contrast, pitch-based carbon fibers possess a highly aligned, graphitic microstructure with larger crystallite sizes, offering exceptional stiffness and tensile strength but lower surface area. These fundamental structural differences determine their respective performance in applications requiring varying balances of strength, conductivity, and toughness.

Mechanical Properties Comparison

Vapor-grown carbon fiber exhibits superior tensile strength and higher modulus compared to pitch-based carbon fiber, making it ideal for applications requiring lightweight and high-strength materials. Pitch-based carbon fibers typically offer greater stiffness and improved thermal conductivity, beneficial in aerospace and electronic industries. The mechanical properties of vapor-grown fibers include enhanced flexibility and toughness, whereas pitch-based fibers excel in rigidity and dimensional stability.

Electrical Conductivity: A Side-by-Side Analysis

Vapor-grown carbon fibers exhibit superior electrical conductivity compared to pitch-based carbon fibers due to their high aspect ratio and well-maintained graphitic structure. Pitch-based carbon fibers, while offering exceptional mechanical strength and thermal stability, typically demonstrate lower electrical conductivity because of their larger crystallite size and less continuous graphitic planes. This makes vapor-grown carbon fibers more suitable for applications requiring efficient electrical current flow, such as in conductive composites and electronic components.

Thermal Stability and Performance

Vapor-grown carbon fiber exhibits superior thermal stability with decomposition temperatures often exceeding 3000degC, making it ideal for high-temperature applications. Pitch-based carbon fiber, while also thermally stable, typically shows enhanced mechanical strength and modulus due to its graphitic microstructure but has slightly lower thermal resistance near 2500degC. The choice between vapor-grown and pitch-based carbon fibers depends on balancing thermal endurance with mechanical performance for specific industrial uses.

Typical Industrial Applications

Vapor-grown carbon fiber (VGCF) is predominantly used in electronics, battery electrodes, and composite materials for aerospace and automotive sectors due to its high electrical conductivity and enhanced mechanical strength. Pitch-based carbon fiber finds typical industrial applications in high-performance sporting goods, aerospace structures, and thermal management systems because of its superior stiffness and thermal stability. Both types are critical in advancing lightweight structural components and energy storage technologies.

Cost Efficiency and Scalability

Vapor-grown carbon fiber offers greater cost efficiency due to lower raw material expenses and simpler manufacturing processes compared to pitch-based carbon fiber, which involves high-temperature treatment of petroleum pitch making it more expensive. Scalability favors vapor-grown carbon fiber as its production can be rapidly increased using chemical vapor deposition techniques, while pitch-based carbon fiber's complex heat-treating steps limit large-scale production speed. Companies seeking affordable, high-volume carbon fiber solutions typically prefer vapor-grown options for their balance of performance and economic feasibility.

Environmental Impact and Sustainability

Vapor-grown carbon fiber offers a lower environmental impact than pitch-based carbon fiber due to its production process that requires less energy and generates fewer emissions. It utilizes chemical vapor deposition, which allows for greater control over fiber properties and reduces waste compared to the energy-intensive graphitization of pitch-based fibers. This makes vapor-grown carbon fibers more sustainable, supporting eco-friendly manufacturing in industries such as aerospace and automotive.

Future Trends in Carbon Fiber Technology

Vapor-grown carbon fiber offers enhanced conductivity and lightweight properties compared to traditional pitch-based carbon fiber, positioning it as a key material in aerospace and electronics advancements. Emerging trends indicate increased integration of vapor-grown fibers into composite materials for improved mechanical performance and thermal management. Innovations focus on scalable production techniques and hybridizing vapor-grown and pitch-based fibers to optimize strength-to-weight ratios for next-generation applications.

Vapor-grown carbon fiber vs Pitch-based carbon fiber Infographic

materialdif.com

materialdif.com