Metallurgical coke, derived from coal through destructive distillation, is essential for steel production due to its high carbon content and structural strength, enabling efficient blast furnace operations. Petroleum coke, a byproduct of oil refining, contains higher sulfur content and is mainly used as a fuel source in power generation and cement kilns rather than metallurgical processes. The choice between metallurgical coke and petroleum coke depends on specific industrial requirements, including purity, carbon content, and environmental regulations.

Table of Comparison

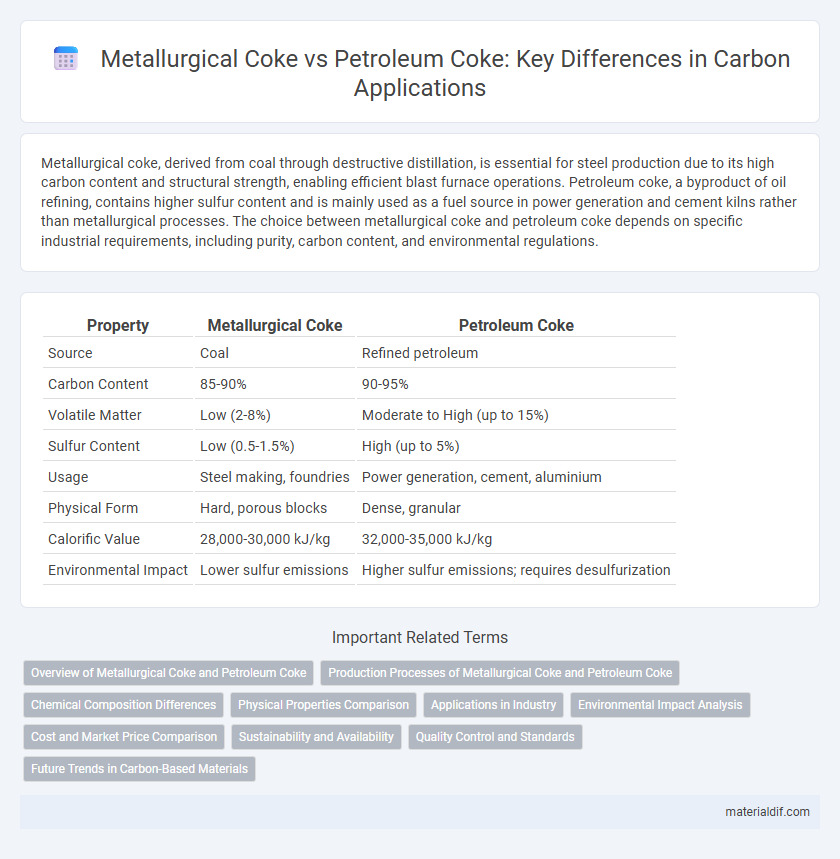

| Property | Metallurgical Coke | Petroleum Coke |

|---|---|---|

| Source | Coal | Refined petroleum |

| Carbon Content | 85-90% | 90-95% |

| Volatile Matter | Low (2-8%) | Moderate to High (up to 15%) |

| Sulfur Content | Low (0.5-1.5%) | High (up to 5%) |

| Usage | Steel making, foundries | Power generation, cement, aluminium |

| Physical Form | Hard, porous blocks | Dense, granular |

| Calorific Value | 28,000-30,000 kJ/kg | 32,000-35,000 kJ/kg |

| Environmental Impact | Lower sulfur emissions | Higher sulfur emissions; requires desulfurization |

Overview of Metallurgical Coke and Petroleum Coke

Metallurgical coke, derived from coal, is essential for steelmaking due to its high carbon content, strong structural properties, and low sulfur levels, which enhance blast furnace efficiency. Petroleum coke, a byproduct of crude oil refining, features higher sulfur content and lower reactivity, making it more suitable for power generation and cement production rather than metallurgical applications. The selection between metallurgical coke and petroleum coke depends on their chemical composition, thermal properties, and specific industrial requirements.

Production Processes of Metallurgical Coke and Petroleum Coke

Metallurgical coke is produced through the destructive distillation of bituminous coal in coke ovens at high temperatures, driving off volatile components and forming a porous, carbon-rich solid essential for steelmaking. Petroleum coke, a byproduct of the oil refining process, is generated via thermal cracking or coking units where heavy residual oil fractions are thermally decomposed and solidified into carbon-rich coke. The distinct production processes result in metallurgical coke having a higher carbon content and structural strength compared to petroleum coke, influencing their respective applications in industrial metallurgy and energy sectors.

Chemical Composition Differences

Metallurgical coke primarily consists of fixed carbon with low sulfur and volatile matter, making it ideal for steelmaking processes requiring high reactivity and strength. Petroleum coke contains higher sulfur and volatile compounds, including metals such as vanadium and nickel, which can impact combustion emissions and corrosion. The distinct chemical compositions influence their industrial applications, with metallurgical coke favored for blast furnaces and petroleum coke commonly used in power generation and cement production.

Physical Properties Comparison

Metallurgical coke exhibits higher porosity, greater mechanical strength, and more uniform size distribution compared to petroleum coke, making it ideal for blast furnace operations. Petroleum coke typically possesses higher sulfur content, lower fixed carbon, and denser physical structure, which influences its suitability in energy generation rather than metallurgical processes. The distinct differences in properties like volatile matter content and ash composition directly impact their respective performance and environmental footprint in industrial applications.

Applications in Industry

Metallurgical coke is primarily used in the steel industry as a crucial fuel and reducing agent in blast furnaces, facilitating the smelting of iron ore into molten iron. Petroleum coke, derived from oil refining, serves as a high-carbon fuel source in power generation, cement kilns, and various industrial boilers due to its dense energy content. Both types of coke offer distinct advantages aligned with their carbon content and impurity levels, influencing their suitability across metallurgical and energy-intensive industrial processes.

Environmental Impact Analysis

Metallurgical coke produces lower sulfur dioxide (SO2) and nitrogen oxides (NOx) emissions compared to petroleum coke, significantly reducing air pollution and acid rain potential. Petroleum coke exhibits a higher carbon content and energy density but generates more greenhouse gases and heavy metal pollutants, intensifying its environmental footprint. Lifecycle assessments highlight metallurgical coke as relatively cleaner, with petroleum coke requiring advanced emissions control technologies to meet environmental regulations.

Cost and Market Price Comparison

Metallurgical coke generally commands a higher market price than petroleum coke due to its crucial role in steel production and superior carbon content, which enhances its industrial value. Petroleum coke is typically less expensive, making it a cost-effective option for power generation and cement manufacturing, despite its lower purity and higher sulfur content. Price volatility in both markets is influenced by crude oil fluctuations, regulatory policies, and demand shifts in steel and energy sectors.

Sustainability and Availability

Metallurgical coke, derived from coal, offers critical strength for steel production but faces sustainability challenges due to high carbon emissions and limited coal reserves. Petroleum coke, a byproduct of oil refining, provides an abundant alternative with higher energy content but poses environmental risks from sulfur and heavy metal content. Sustainable steel manufacturing demands innovations in reducing emissions and diversifying coke sources to balance availability with environmental impact.

Quality Control and Standards

Metallurgical coke undergoes stringent quality control measures to ensure high carbon content, low sulfur, and optimal strength for steelmaking applications, meeting standards such as ASTM D5342 and ISO 17246. Petroleum coke quality is evaluated based on sulfur content, calorific value, and volatile matter, adhering to specifications like API standards and ASTM D5865 to ensure suitability for energy production. Consistent monitoring of physical and chemical properties in both cokes is essential for maintaining performance efficiency and environmental compliance in industrial processes.

Future Trends in Carbon-Based Materials

Metallurgical coke remains essential for traditional steel production, but future trends highlight increasing demand for petroleum coke in energy generation and industrial carbon applications due to its higher carbon content and lower impurities. Innovations in carbon-based materials, including graphene and carbon nanotubes, are poised to complement or replace conventional cokes by offering superior strength and conductivity. Sustainable practices and regulatory pressures drive the development of cleaner production technologies for both metallurgical and petroleum coke to reduce carbon emissions.

Metallurgical Coke vs Petroleum Coke Infographic

materialdif.com

materialdif.com