Sintered carbon offers superior durability and heat resistance due to its manufacturing process, making it ideal for demanding mechanical applications. Coated carbon, on the other hand, provides enhanced surface properties such as reduced friction and improved corrosion resistance by applying a protective layer. Choosing between sintered and coated carbon depends on the specific requirements of wear resistance, thermal stability, and environmental exposure in the intended use.

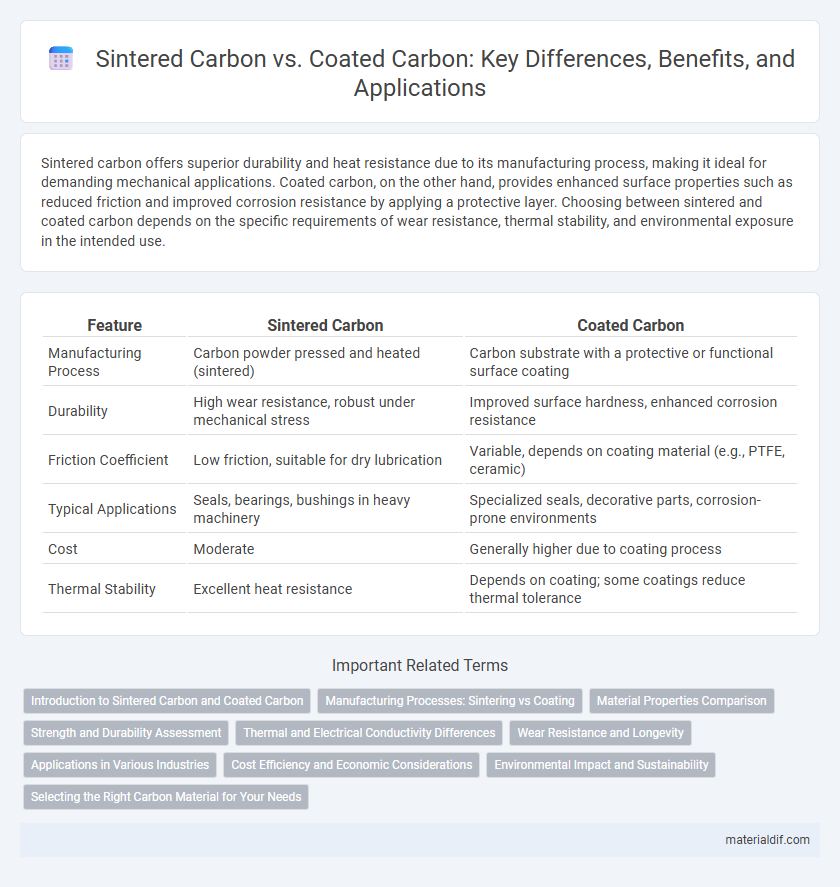

Table of Comparison

| Feature | Sintered Carbon | Coated Carbon |

|---|---|---|

| Manufacturing Process | Carbon powder pressed and heated (sintered) | Carbon substrate with a protective or functional surface coating |

| Durability | High wear resistance, robust under mechanical stress | Improved surface hardness, enhanced corrosion resistance |

| Friction Coefficient | Low friction, suitable for dry lubrication | Variable, depends on coating material (e.g., PTFE, ceramic) |

| Typical Applications | Seals, bearings, bushings in heavy machinery | Specialized seals, decorative parts, corrosion-prone environments |

| Cost | Moderate | Generally higher due to coating process |

| Thermal Stability | Excellent heat resistance | Depends on coating; some coatings reduce thermal tolerance |

Introduction to Sintered Carbon and Coated Carbon

Sintered carbon is a porous material formed by compressing and heating carbon powder below its melting point, enabling lubrication retention and enhanced wear resistance ideal for mechanical seals and bearings. Coated carbon involves applying a thin, uniform layer of carbon-based material onto substrates to improve surface properties such as hardness, corrosion resistance, and friction reduction. Both sintered and coated carbon are critical in industrial applications requiring durable, low-friction, and chemically resistant components.

Manufacturing Processes: Sintering vs Coating

Sintered carbon is manufactured through a high-temperature sintering process that compacts carbon powders into a dense, porous structure, enhancing mechanical strength and thermal stability. In contrast, coated carbon involves applying a thin, uniform carbon layer onto a substrate via chemical vapor deposition (CVD) or physical vapor deposition (PVD), which improves surface wear resistance and reduces friction. The sintering process results in a bulk material with integral carbon properties, while coating techniques modify surface characteristics without altering the core material.

Material Properties Comparison

Sintered carbon offers superior porosity and self-lubricating properties, enabling enhanced wear resistance and reduced friction in high-temperature applications. Coated carbon features a protective layer that improves corrosion resistance and surface hardness, extending lifespan under abrasive conditions. Both materials excel in mechanical strength, but sintered carbon is preferred for dynamic environments while coated carbon suits static or chemically aggressive settings.

Strength and Durability Assessment

Sintered carbon exhibits superior strength due to its dense microstructure formed under high temperature and pressure, resulting in enhanced durability and resistance to wear and corrosion. Coated carbon relies on a protective layer to improve surface hardness, but may be more prone to coating degradation over time, reducing long-term durability. Strength assessments favor sintered carbon for demanding mechanical applications, while coated carbon suits environments requiring specific surface properties with moderate structural loads.

Thermal and Electrical Conductivity Differences

Sintered carbon exhibits higher thermal conductivity due to its dense, interconnected carbon structure, facilitating efficient heat transfer. Coated carbon, with its thin surface layer, often shows reduced electrical conductivity as the coating can act as an insulating barrier, limiting electron flow. Thermal conductivity in sintered carbon typically outperforms coated carbon, while electrical conductivity varies significantly depending on the coating material used.

Wear Resistance and Longevity

Sintered carbon offers superior wear resistance and longevity due to its dense, uniform microstructure created through high-temperature compression, which enhances durability in high-friction environments. Coated carbon combines a porous carbon base with a protective outer layer, improving surface hardness and resistance to wear but may exhibit shorter lifespan if the coating degrades or delaminates. Choosing between sintered and coated carbon depends on application-specific demands for continuous wear resistance versus surface protection and maintenance cycles.

Applications in Various Industries

Sintered carbon, known for its high porosity and self-lubricating properties, is widely utilized in automotive brake systems, industrial valves, and aerospace components requiring wear resistance and thermal stability. Coated carbon offers enhanced corrosion resistance and durability, making it ideal for chemical processing equipment, electrical contacts, and sealing solutions in harsh environments. Both materials serve critical roles in industries demanding reliability under extreme conditions, with sintered carbon favored for mechanical applications and coated carbon preferred for chemical and electrical uses.

Cost Efficiency and Economic Considerations

Sintered carbon components offer higher initial manufacturing costs but provide superior durability and longer service life, reducing replacement frequency and overall maintenance expenses. Coated carbon, while generally less expensive upfront, may require more frequent recoating or replacement, impacting long-term cost efficiency. Evaluating total lifecycle costs, including material wear rates and maintenance intervals, is essential for optimal economic decision-making in carbon-based applications.

Environmental Impact and Sustainability

Sintered carbon components offer superior durability and reduced wear, leading to longer lifespans and lower material consumption compared to coated carbon, which often requires frequent replacement due to coating degradation. The production of sintered carbon typically involves less chemical processing and fewer hazardous substances, resulting in a smaller environmental footprint and reduced emissions. Sustainable manufacturing practices in sintered carbon align with circular economy principles by enabling efficient recycling and minimizing waste, whereas coated carbon's reliance on synthetic coatings poses challenges for eco-friendly disposal.

Selecting the Right Carbon Material for Your Needs

Sintered carbon offers exceptional durability and heat resistance, making it ideal for high-load and high-temperature applications such as mechanical seals and industrial machinery. Coated carbon, enhanced with materials like graphite or PTFE, provides superior friction reduction and chemical resistance, suited for applications requiring low wear and smooth operation. Selecting the right carbon material depends on factors like operational temperature, load conditions, chemical exposure, and desired lifespan.

Sintered Carbon vs Coated Carbon Infographic

materialdif.com

materialdif.com