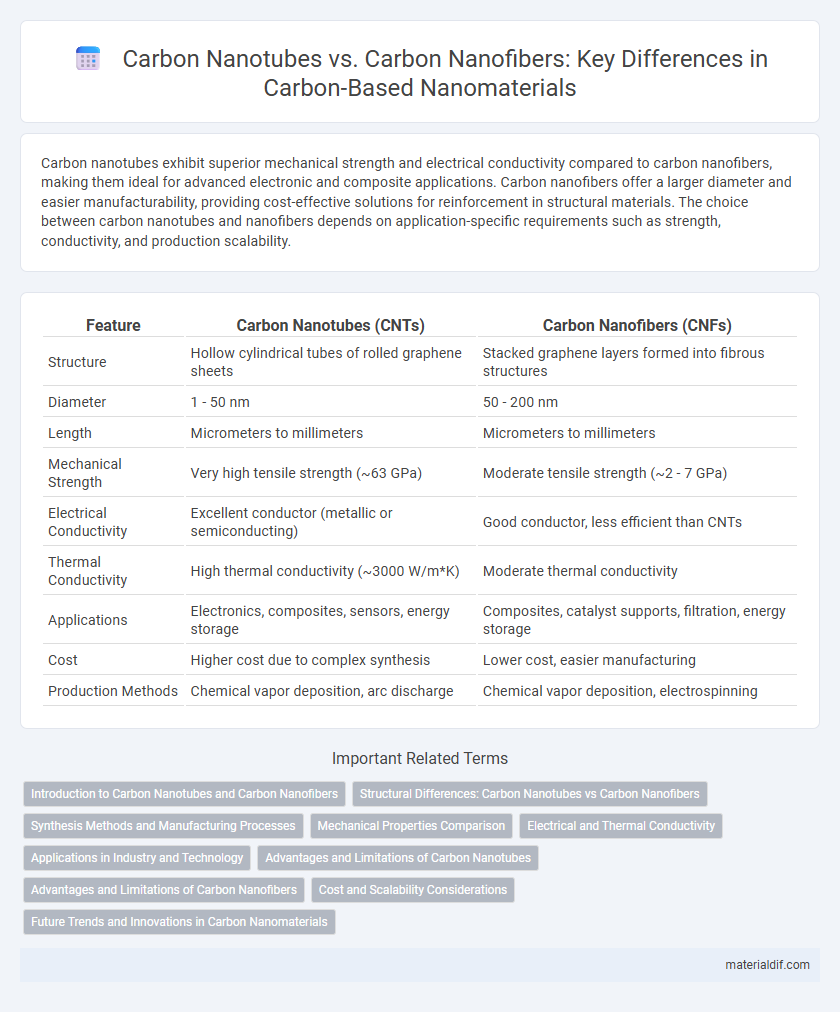

Carbon nanotubes exhibit superior mechanical strength and electrical conductivity compared to carbon nanofibers, making them ideal for advanced electronic and composite applications. Carbon nanofibers offer a larger diameter and easier manufacturability, providing cost-effective solutions for reinforcement in structural materials. The choice between carbon nanotubes and nanofibers depends on application-specific requirements such as strength, conductivity, and production scalability.

Table of Comparison

| Feature | Carbon Nanotubes (CNTs) | Carbon Nanofibers (CNFs) |

|---|---|---|

| Structure | Hollow cylindrical tubes of rolled graphene sheets | Stacked graphene layers formed into fibrous structures |

| Diameter | 1 - 50 nm | 50 - 200 nm |

| Length | Micrometers to millimeters | Micrometers to millimeters |

| Mechanical Strength | Very high tensile strength (~63 GPa) | Moderate tensile strength (~2 - 7 GPa) |

| Electrical Conductivity | Excellent conductor (metallic or semiconducting) | Good conductor, less efficient than CNTs |

| Thermal Conductivity | High thermal conductivity (~3000 W/m*K) | Moderate thermal conductivity |

| Applications | Electronics, composites, sensors, energy storage | Composites, catalyst supports, filtration, energy storage |

| Cost | Higher cost due to complex synthesis | Lower cost, easier manufacturing |

| Production Methods | Chemical vapor deposition, arc discharge | Chemical vapor deposition, electrospinning |

Introduction to Carbon Nanotubes and Carbon Nanofibers

Carbon nanotubes (CNTs) are cylindrical nanostructures composed of rolled graphene sheets, exhibiting exceptional mechanical strength, electrical conductivity, and thermal stability. Carbon nanofibers (CNFs) are composed of stacked graphene layers in a conical or platelet morphology, offering high surface area and excellent rigidity but comparatively lower electrical conductivity than CNTs. Both CNTs and CNFs serve as advanced materials in composites, energy storage, and electronics due to their unique nanoscale properties and structural differences.

Structural Differences: Carbon Nanotubes vs Carbon Nanofibers

Carbon nanotubes consist of rolled graphene sheets forming cylindrical tubes with diameters typically in the nanometer range, exhibiting a hollow core and seamless walls. Carbon nanofibers have stacked, conical, or platelet graphene layers arranged in a more irregular, fibrous structure with larger diameters and a solid core. These distinct structural differences influence their mechanical, electrical, and thermal properties, making carbon nanotubes generally stronger and more conductive compared to carbon nanofibers.

Synthesis Methods and Manufacturing Processes

Carbon nanotubes are primarily synthesized using chemical vapor deposition (CVD), arc discharge, and laser ablation methods, which enable precise control over their diameter and chirality. Carbon nanofibers are typically produced through electrospinning and thermal chemical vapor deposition, focusing on scalable fiber formation with less emphasis on atomic-level structure. Manufacturing processes for carbon nanotubes often require high temperature and catalyst control for single or multi-walled configurations, whereas carbon nanofiber production centers on fiber morphology and bulk material properties for composite reinforcement applications.

Mechanical Properties Comparison

Carbon nanotubes exhibit exceptional tensile strength and Young's modulus, often surpassing 1 TPa and 100 GPa respectively, making them one of the strongest known materials at the nanoscale. Carbon nanofibers, while also possessing high strength and stiffness, typically show lower mechanical performance due to their larger diameter and less perfect graphitic structure. The superior mechanical properties of carbon nanotubes, including their flexibility and resilience, make them highly suitable for advanced composite materials requiring enhanced durability and load-bearing capacity.

Electrical and Thermal Conductivity

Carbon nanotubes exhibit superior electrical conductivity compared to carbon nanofibers due to their unique atomic structure and high aspect ratio, enabling efficient electron transport. Their thermal conductivity also surpasses that of carbon nanofibers, reaching values up to 3,000 W/m*K, whereas carbon nanofibers typically range between 50-500 W/m*K. This remarkable performance makes carbon nanotubes highly suitable for advanced electronic and thermal management applications.

Applications in Industry and Technology

Carbon nanotubes exhibit exceptional electrical conductivity and mechanical strength, making them ideal for applications in electronics, aerospace, and energy storage devices. Carbon nanofibers, with their larger diameter and porous structure, are widely used in composite materials, filtration systems, and as catalyst supports in chemical industries. Both materials enhance performance and durability in industrial applications but are selected based on specific mechanical and conductive property requirements.

Advantages and Limitations of Carbon Nanotubes

Carbon nanotubes (CNTs) exhibit exceptional tensile strength, electrical conductivity, and thermal stability compared to carbon nanofibers, making them superior for applications in nanoelectronics, composite materials, and energy storage. Their unique cylindrical nanostructure permits higher aspect ratios and quantum mechanical effects that enhance mechanical reinforcement and electron transport. Limitations of CNTs include high production costs, challenges in large-scale uniform synthesis, and potential toxicity concerns that hinder widespread commercial use.

Advantages and Limitations of Carbon Nanofibers

Carbon nanofibers offer advantages such as lower production costs and easier scalability compared to carbon nanotubes, making them suitable for large-scale industrial applications. They exhibit good electrical conductivity, mechanical strength, and thermal stability but possess lower tensile strength and aspect ratios than carbon nanotubes, limiting their effectiveness in high-performance composite materials. Challenges include achieving uniform dispersion and optimizing fiber alignment to enhance mechanical properties for applications in electronics, energy storage, and reinforcement materials.

Cost and Scalability Considerations

Carbon nanotubes offer exceptional strength and electrical conductivity but come with higher production costs and complex manufacturing processes that limit scalability. In contrast, carbon nanofibers provide a more cost-effective alternative with simpler synthesis methods, enabling larger-scale production at lower expenses. The choice between these materials often hinges on balancing budget constraints with required performance levels in applications.

Future Trends and Innovations in Carbon Nanomaterials

Carbon nanotubes exhibit superior electrical conductivity and mechanical strength compared to carbon nanofibers, driving advancements in flexible electronics and high-performance composites. Ongoing innovations focus on hybrid nanomaterials combining carbon nanotubes and nanofibers to enhance thermal management and energy storage systems. Emerging research in scalable production techniques and surface functionalization aims to expand the applications of carbon nanomaterials in aerospace and biomedical fields.

Carbon Nanotubes vs Carbon Nanofibers Infographic

materialdif.com

materialdif.com