Chopped carbon fibers provide enhanced isotropic strength and improved surface finish in Carbon PET composites, making them ideal for complex geometries. Continuous carbon fibers deliver superior tensile strength and stiffness, ensuring maximum load-bearing capacity and structural integrity. Choosing between chopped and continuous carbon depends on balancing manufacturing flexibility with mechanical performance requirements.

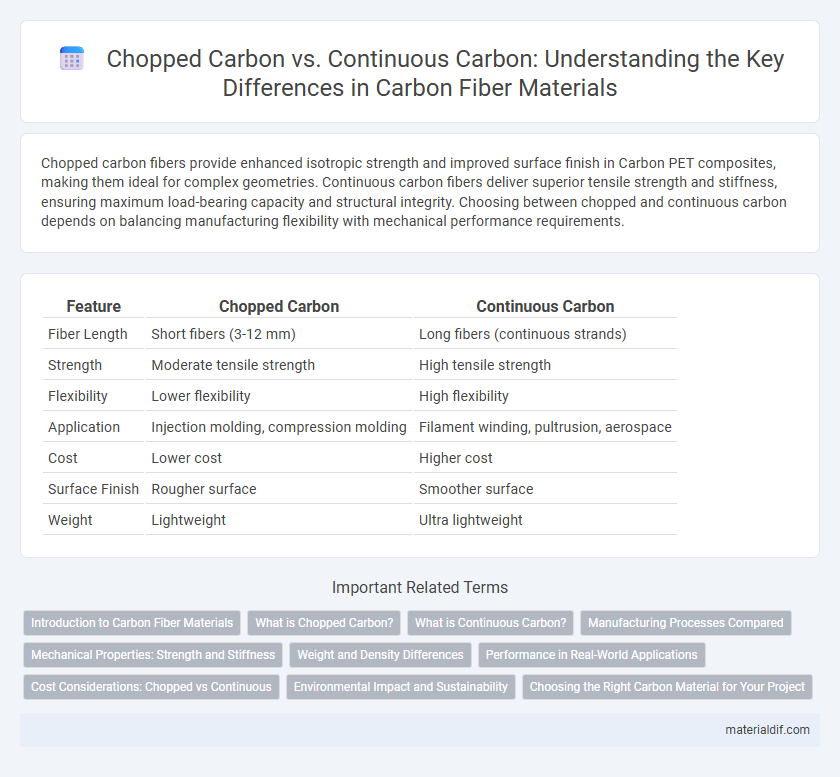

Table of Comparison

| Feature | Chopped Carbon | Continuous Carbon |

|---|---|---|

| Fiber Length | Short fibers (3-12 mm) | Long fibers (continuous strands) |

| Strength | Moderate tensile strength | High tensile strength |

| Flexibility | Lower flexibility | High flexibility |

| Application | Injection molding, compression molding | Filament winding, pultrusion, aerospace |

| Cost | Lower cost | Higher cost |

| Surface Finish | Rougher surface | Smoother surface |

| Weight | Lightweight | Ultra lightweight |

Introduction to Carbon Fiber Materials

Chopped carbon fibers consist of short strands cut into small lengths, offering improved moldability and isotropic properties for complex shapes in composite manufacturing. Continuous carbon fibers, made of long, unbroken filaments, provide superior tensile strength, stiffness, and durability, ideal for load-bearing applications in aerospace and automotive industries. Selecting between chopped and continuous carbon fibers depends on the balance between structural performance requirements and design flexibility in carbon composite materials.

What is Chopped Carbon?

Chopped carbon consists of short, randomly oriented carbon fiber segments used to reinforce composite materials, enhancing strength and stiffness while allowing easier molding into complex shapes. This form of carbon fiber offers improved isotropic properties compared to continuous carbon, making it ideal for components with intricate geometries or impact resistance requirements. Industries such as automotive and aerospace utilize chopped carbon for lightweight, durable parts where cost-efficiency and design flexibility are critical.

What is Continuous Carbon?

Continuous carbon refers to carbon fibers manufactured as long, unbroken strands that provide superior strength, stiffness, and conductivity compared to chopped carbon fibers. These continuous fibers are widely used in advanced composites for aerospace, automotive, and sporting goods applications due to their enhanced load-bearing capacity and uniform mechanical properties. The seamless nature of continuous carbon enables improved bonding within polymer matrices, resulting in lightweight and high-performance materials.

Manufacturing Processes Compared

Chopped carbon fibers are produced through mechanical chopping of continuous fiber tows, offering ease of integration into injection molding and compression molding processes for complex geometries. Continuous carbon fibers undergo processes like filament winding or pultrusion, enabling uniform fiber alignment and superior tensile strength in long, unbroken strands suitable for high-performance composites. Manufacturing with chopped carbon typically results in isotropic mechanical properties and faster molding cycles, while continuous carbon demands precise handling but delivers optimized strength-to-weight ratios.

Mechanical Properties: Strength and Stiffness

Chopped carbon fibers exhibit lower tensile strength and stiffness compared to continuous carbon fibers due to their shorter fiber lengths and random orientation, which disrupts load transfer efficiency. Continuous carbon fibers provide superior mechanical properties, with high strength and stiffness resulting from aligned, unbroken fibers that effectively distribute stress along their length. These differences make continuous carbon preferred for structural applications requiring maximum load-bearing capacity, while chopped carbon is suited for molded parts needing complex shapes but moderate mechanical performance.

Weight and Density Differences

Chopped carbon fibers consist of short strands, resulting in a composite with lower density and reduced weight compared to continuous carbon fibers, which are long, unbroken filaments providing superior strength and stiffness. Continuous carbon demonstrates higher tensile strength and uniform density, ideal for load-bearing applications, whereas chopped carbon offers easier moldability and cost-effectiveness due to its lower fiber length. Weight savings in chopped carbon materials benefit automotive and sporting goods industries, while continuous carbon is preferred in aerospace and high-performance structural components for critical weight-to-strength optimization.

Performance in Real-World Applications

Chopped carbon fibers offer enhanced isotropic strength and ease of molding, making them ideal for complex geometries in automotive and consumer goods, while continuous carbon fibers deliver superior tensile strength and stiffness critical for aerospace and high-performance sports equipment. Real-world performance of chopped carbon composites often results in improved impact resistance and cost-effectiveness, whereas continuous carbon composites excel in load-bearing applications due to their unidirectional fiber alignment. Optimizing the choice between chopped and continuous carbon depends on specific application demands like structural integrity, weight reduction, and manufacturing scalability.

Cost Considerations: Chopped vs Continuous

Chopped carbon fibers offer lower material costs and simpler processing, making them ideal for budget-sensitive applications with less stringent mechanical requirements. Continuous carbon fibers provide superior strength and stiffness but come with higher raw material expenses and more complex manufacturing processes. Selecting between chopped and continuous carbon fibers depends on balancing performance needs with cost efficiency in composite production.

Environmental Impact and Sustainability

Chopped carbon fibers, typically derived from recycled or lower-grade materials, offer benefits in reducing waste and energy consumption during production compared to continuous carbon fibers, which require more energy-intensive processes. Continuous carbon fibers provide superior strength and durability, allowing longer product lifespan and potential for recycling, yet their manufacturing emits higher CO2 levels. Evaluating environmental impact and sustainability demands balancing the lower immediate footprint of chopped carbon with the lifecycle advantages of continuous carbon fibers.

Choosing the Right Carbon Material for Your Project

Chopped carbon fibers provide excellent isotropic strength and are ideal for molded parts with complex geometries, offering cost-effective reinforcement in automotive and aerospace applications. Continuous carbon fibers deliver superior tensile strength and stiffness, making them suitable for high-performance structural components such as sporting goods and aerospace frames. Selecting the right carbon material depends on balancing mechanical requirements, part design complexity, and budget constraints to optimize performance and manufacturability.

Chopped Carbon vs Continuous Carbon Infographic

materialdif.com

materialdif.com