Carbon composites offer exceptional strength-to-weight ratios and excellent fatigue resistance, making them ideal for aerospace and automotive applications. Carbon ceramics provide superior thermal stability and high wear resistance, which are crucial for high-temperature environments such as brake systems and turbine engines. Choosing between carbon composites and carbon ceramics depends on the application's mechanical performance, thermal requirements, and environmental conditions.

Table of Comparison

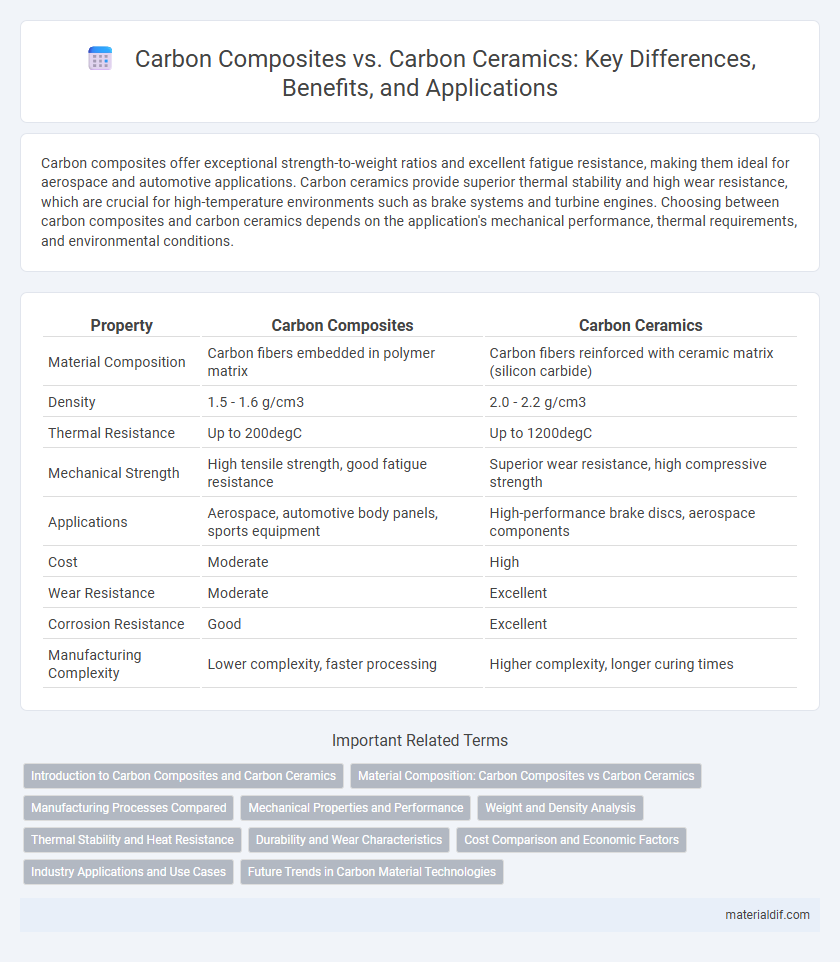

| Property | Carbon Composites | Carbon Ceramics |

|---|---|---|

| Material Composition | Carbon fibers embedded in polymer matrix | Carbon fibers reinforced with ceramic matrix (silicon carbide) |

| Density | 1.5 - 1.6 g/cm3 | 2.0 - 2.2 g/cm3 |

| Thermal Resistance | Up to 200degC | Up to 1200degC |

| Mechanical Strength | High tensile strength, good fatigue resistance | Superior wear resistance, high compressive strength |

| Applications | Aerospace, automotive body panels, sports equipment | High-performance brake discs, aerospace components |

| Cost | Moderate | High |

| Wear Resistance | Moderate | Excellent |

| Corrosion Resistance | Good | Excellent |

| Manufacturing Complexity | Lower complexity, faster processing | Higher complexity, longer curing times |

Introduction to Carbon Composites and Carbon Ceramics

Carbon composites consist of carbon fibers embedded in a polymer matrix, offering high strength-to-weight ratio and excellent fatigue resistance for aerospace and automotive applications. Carbon ceramics, made from carbon bonded with ceramic materials like silicon carbide or carbon-carbon composites, provide superior thermal stability, wear resistance, and oxidation resistance at high temperatures. Both materials leverage carbon's unique properties but serve distinct roles based on mechanical demands and environmental exposure.

Material Composition: Carbon Composites vs Carbon Ceramics

Carbon composites consist of carbon fibers embedded within a polymer or resin matrix, combining lightweight properties with high tensile strength and flexibility. In contrast, carbon ceramics are primarily composed of carbon reinforced with ceramic materials like silicon carbide, offering superior thermal stability, hardness, and resistance to wear at elevated temperatures. The material composition of carbon composites favors applications requiring durability and weight reduction, whereas carbon ceramics excel in high-temperature environments demanding enhanced mechanical strength and oxidation resistance.

Manufacturing Processes Compared

Carbon composites are manufactured through layering carbon fibers with resin matrices, typically using processes like resin transfer molding and autoclave curing, which allow for lightweight and high-strength structures. Carbon ceramics involve sintering carbon with ceramic materials at high temperatures, producing components with exceptional thermal resistance and wear properties but requiring complex and energy-intensive manufacturing. While carbon composites offer easier scalability and design flexibility, carbon ceramics demand advanced processing techniques for precise microstructure control and enhanced durability.

Mechanical Properties and Performance

Carbon composites offer high tensile strength, low weight, and excellent fatigue resistance, making them ideal for aerospace and automotive applications requiring flexibility and impact absorption. Carbon ceramics exhibit superior hardness, thermal stability, and wear resistance, suited for brake systems and high-temperature environments demanding durability under extreme conditions. Both materials provide distinct mechanical advantages, with composites excelling in lightweight performance and ceramics ensuring long-term structural integrity under thermal stress.

Weight and Density Analysis

Carbon composites exhibit significantly lower density, typically around 1.5-1.6 g/cm3, compared to carbon ceramics, which range from 2.0 to 3.0 g/cm3, resulting in lighter components ideal for automotive and aerospace applications. The reduced weight of carbon composites enhances fuel efficiency and performance, while carbon ceramics offer superior thermal resistance and wear properties despite their higher density. Understanding this trade-off in weight and density is crucial for selecting materials that balance structural efficiency and durability in advanced engineering designs.

Thermal Stability and Heat Resistance

Carbon composites exhibit excellent thermal stability due to their low thermal expansion and high strength retention at elevated temperatures, making them ideal for aerospace and automotive applications. Carbon ceramics surpass carbon composites in heat resistance, maintaining structural integrity at temperatures exceeding 2000degC, which suits high-temperature industrial processes and thermal barrier coatings. Both materials offer unique advantages, with carbon ceramics favored for extreme heat environments and carbon composites preferred for applications requiring a balance of lightweight properties and thermal durability.

Durability and Wear Characteristics

Carbon composites exhibit superior durability due to their high tensile strength and flexibility, making them ideal for applications requiring resistance to dynamic stress and fracture. Carbon ceramics offer exceptional wear resistance and thermal stability, which enhances longevity in high-temperature environments such as braking systems and turbine components. The combination of carbon composites' toughness and carbon ceramics' hardness results in materials optimized for diverse industrial uses with extended service life.

Cost Comparison and Economic Factors

Carbon composites generally offer a lower-cost solution compared to carbon ceramics due to less energy-intensive manufacturing processes and more readily available raw materials, reducing overall production expenses. Carbon ceramics involve high-temperature sintering and specialized fabrication techniques, significantly increasing material and processing costs. Economic factors such as scalability, lifecycle performance, and maintenance expenses also favor carbon composites in applications requiring cost efficiency and moderate durability.

Industry Applications and Use Cases

Carbon composites excel in aerospace and automotive industries due to their high strength-to-weight ratio, enhancing fuel efficiency and performance in aircraft structures and racing cars. Carbon ceramics dominate in high-temperature applications such as brake systems for high-performance vehicles and aerospace components where thermal resistance and durability are critical. Both materials are essential for industries demanding lightweight solutions with specific mechanical and thermal properties.

Future Trends in Carbon Material Technologies

Carbon composites demonstrate increasing adoption in aerospace and automotive industries due to their high strength-to-weight ratio and design flexibility, driving innovation in lightweight structures and sustainable manufacturing. Carbon ceramics, known for exceptional thermal stability and wear resistance, are advancing in high-performance brake systems and aerospace engine components, emphasizing durability under extreme conditions. Emerging research focuses on hybrid materials combining carbon composites and ceramics to enhance multifunctional properties, aiming to meet future demands for efficiency, resilience, and environmental sustainability in carbon material technologies.

Carbon Composites vs Carbon Ceramics Infographic

materialdif.com

materialdif.com