Vapor grown carbon fiber (VGCF) offers higher electrical conductivity and superior thermal management compared to PAN-based carbon fiber, making it ideal for advanced composite applications requiring enhanced performance. VGCF features a unique tubular structure with a higher surface area, which improves bonding with matrix materials and reinforces mechanical strength. While PAN-based carbon fiber excels in tensile strength and stiffness, VGCF provides better versatility for use in electronic devices and energy storage systems.

Table of Comparison

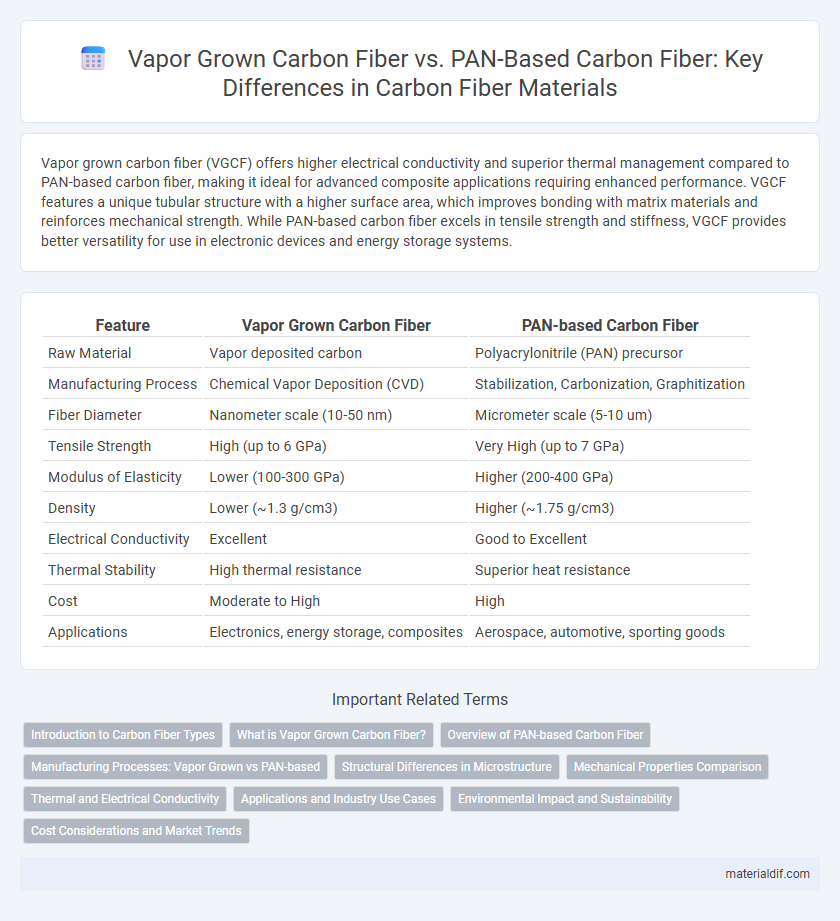

| Feature | Vapor Grown Carbon Fiber | PAN-based Carbon Fiber |

|---|---|---|

| Raw Material | Vapor deposited carbon | Polyacrylonitrile (PAN) precursor |

| Manufacturing Process | Chemical Vapor Deposition (CVD) | Stabilization, Carbonization, Graphitization |

| Fiber Diameter | Nanometer scale (10-50 nm) | Micrometer scale (5-10 um) |

| Tensile Strength | High (up to 6 GPa) | Very High (up to 7 GPa) |

| Modulus of Elasticity | Lower (100-300 GPa) | Higher (200-400 GPa) |

| Density | Lower (~1.3 g/cm3) | Higher (~1.75 g/cm3) |

| Electrical Conductivity | Excellent | Good to Excellent |

| Thermal Stability | High thermal resistance | Superior heat resistance |

| Cost | Moderate to High | High |

| Applications | Electronics, energy storage, composites | Aerospace, automotive, sporting goods |

Introduction to Carbon Fiber Types

Vapor grown carbon fiber (VGCF) features a unique morphology produced through chemical vapor deposition, resulting in highly conductive and electrically efficient fibers used in advanced composite applications. PAN-based carbon fiber derives from polyacrylonitrile and is renowned for its superior tensile strength and stiffness, making it the dominant material in aerospace and automotive industries. Each fiber type offers distinct structural properties, cost factors, and performance benefits tailored to specific engineering requirements.

What is Vapor Grown Carbon Fiber?

Vapor Grown Carbon Fiber (VGCF) is a type of carbon fiber produced through chemical vapor deposition, resulting in ultra-fine, high-aspect-ratio fibers with exceptional electrical conductivity and mechanical strength. VGCF fibers exhibit a unique cylindrical morphology and smaller diameter compared to traditional PAN-based carbon fibers, enhancing their performance in composite materials and electromagnetic shielding applications. These fibers offer superior dispersion within polymer matrices, contributing to improved thermal conductivity and structural integrity in advanced engineering uses.

Overview of PAN-based Carbon Fiber

PAN-based carbon fiber is produced from polyacrylonitrile (PAN) precursors, which undergo stabilization, carbonization, and surface treatment to achieve high tensile strength and modulus. This type of carbon fiber offers superior mechanical properties, with tensile strength typically ranging from 3.5 to 7.0 GPa and modulus between 200 to 600 GPa, making it ideal for aerospace, automotive, and sporting goods applications. PAN-based carbon fibers provide excellent thermal stability and chemical resistance, contributing to their widespread use in high-performance composites.

Manufacturing Processes: Vapor Grown vs PAN-based

Vapor Grown Carbon Fiber (VGCF) is produced by chemical vapor deposition, where carbon is deposited onto a substrate from a gaseous carbon source, creating a highly pure and conductive fiber. PAN-based Carbon Fiber, derived from polyacrylonitrile, undergoes stabilization, carbonization, and surface treatment in a series of thermal processes that yield strong, lightweight fibers with excellent mechanical properties. The VGCF manufacturing process allows for continuous growth and tunable fiber structures, while PAN-based production emphasizes controlled thermal processes to optimize fiber strength and modulus.

Structural Differences in Microstructure

Vapor grown carbon fiber (VGCF) exhibits a unique microstructure characterized by radially aligned graphene layers forming cylindrical nanotubes, resulting in higher surface area and enhanced electrical conductivity compared to PAN-based carbon fiber. PAN-based carbon fiber features turbostratic graphitic planes with random orientation and microvoids, lending superior tensile strength and stiffness due to its crystalline order. The distinct structural differences between VGCF's tubular morphology and PAN fiber's graphitic layering significantly influence their mechanical and functional properties in composite applications.

Mechanical Properties Comparison

Vapor grown carbon fiber exhibits superior tensile strength and modulus compared to conventional PAN-based carbon fiber due to its unique nanostructured morphology, enhancing load transfer efficiency. PAN-based carbon fibers typically offer higher thermal stability and better fatigue resistance, making them suitable for aerospace and automotive applications. Mechanical property optimization depends on the specific application requirements, balancing vapor grown carbon fiber's strength advantages against PAN-based fiber's durability and thermal performance.

Thermal and Electrical Conductivity

Vapor grown carbon fiber (VGCF) exhibits superior thermal and electrical conductivity compared to traditional PAN-based carbon fiber due to its unique nanoscale structure and high aspect ratio. VGCF achieves thermal conductivity values exceeding 1000 W/mK, significantly enhancing heat dissipation in composite materials. Electrical conductivity of VGCF also surpasses PAN-based fibers, making it ideal for applications requiring efficient current flow and electromagnetic interference shielding.

Applications and Industry Use Cases

Vapor grown carbon fiber (VGCF) offers superior electrical conductivity and thermal management, making it ideal for electronics, energy storage, and aerospace applications requiring enhanced performance at reduced weight. PAN-based carbon fiber dominates in structural applications such as automotive, aerospace, and sporting goods due to its high tensile strength, stiffness, and durability. Industries focusing on lightweight composite materials for mechanical reinforcement primarily rely on PAN-based fibers, while sectors aiming for improved electrical and thermal properties increasingly adopt VGCF.

Environmental Impact and Sustainability

Vapor grown carbon fiber (VGCF) demonstrates significantly lower environmental impact compared to PAN-based carbon fiber due to its energy-efficient manufacturing process that eliminates the need for high-temperature carbonization, reducing carbon emissions and energy consumption. The sustainability of VGCF is enhanced by its potential for recycling and reusing in composite materials, contributing to reduced waste and resource conservation. In contrast, PAN-based carbon fiber production relies heavily on fossil fuels and generates substantial hazardous waste, posing challenges for sustainable manufacturing and end-of-life management.

Cost Considerations and Market Trends

Vapor grown carbon fiber generally incurs higher production costs due to its complex manufacturing process involving chemical vapor deposition, leading to limited large-scale commercial use compared to PAN-based carbon fiber, which benefits from established production technologies and economies of scale. Market trends indicate increasing demand for PAN-based carbon fiber in aerospace, automotive, and sports equipment sectors driven by cost-efficiency and mechanical performance. Emerging applications for vapor grown carbon fiber focus on niche markets requiring exceptional conductivity and thermal properties, although its adoption remains constrained by pricing challenges.

Vapor Grown Carbon Fiber vs PAN-based Carbon Fiber Infographic

materialdif.com

materialdif.com