Carbon composite materials offer superior strength-to-weight ratios and enhanced durability compared to carbon black, which primarily serves as a reinforcing filler in rubber and plastic products. Carbon composites provide structural benefits in aerospace, automotive, and sporting goods due to their lightweight and high stiffness, while carbon black improves conductivity, UV protection, and wear resistance in tires and coatings. Choosing between the two depends on whether the application demands structural integrity or material enhancement.

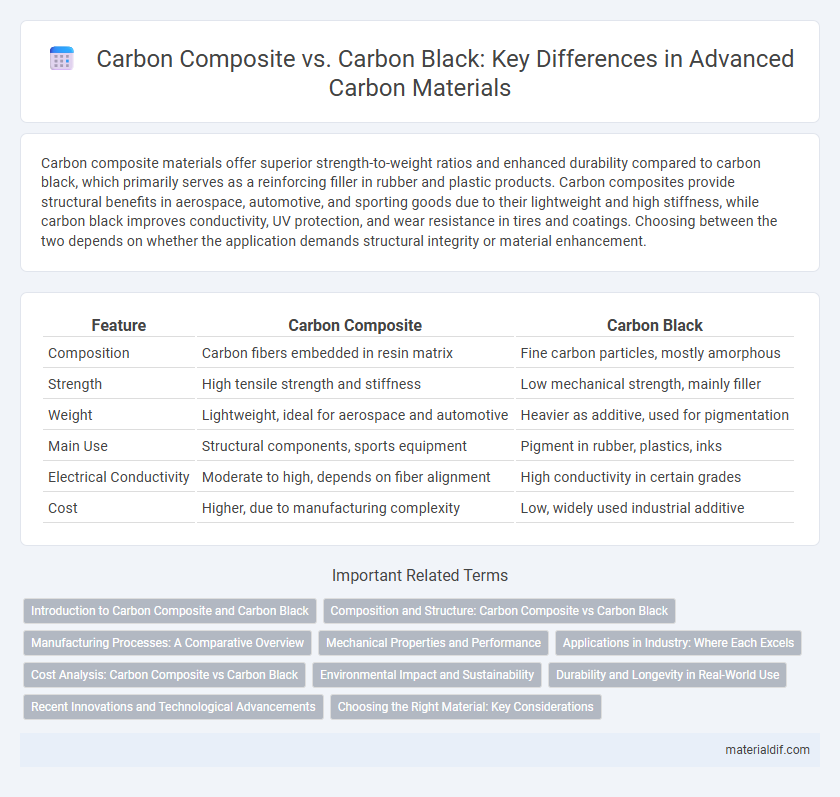

Table of Comparison

| Feature | Carbon Composite | Carbon Black |

|---|---|---|

| Composition | Carbon fibers embedded in resin matrix | Fine carbon particles, mostly amorphous |

| Strength | High tensile strength and stiffness | Low mechanical strength, mainly filler |

| Weight | Lightweight, ideal for aerospace and automotive | Heavier as additive, used for pigmentation |

| Main Use | Structural components, sports equipment | Pigment in rubber, plastics, inks |

| Electrical Conductivity | Moderate to high, depends on fiber alignment | High conductivity in certain grades |

| Cost | Higher, due to manufacturing complexity | Low, widely used industrial additive |

Introduction to Carbon Composite and Carbon Black

Carbon composite materials consist of carbon fibers embedded in a polymer matrix, offering exceptional strength-to-weight ratios and durability used extensively in aerospace, automotive, and sporting goods industries. Carbon black, a fine black powder made from incomplete combustion of hydrocarbons, serves primarily as a reinforcing filler in rubber products and as a pigment in inks, paints, and plastics. While carbon composites enhance structural performance and reduce weight, carbon black improves material toughness, conductivity, and UV resistance in various applications.

Composition and Structure: Carbon Composite vs Carbon Black

Carbon composites consist of carbon fibers embedded in a polymer matrix, providing high strength-to-weight ratio and excellent structural performance. Carbon black is primarily composed of amorphous carbon particles formed by incomplete combustion, featuring a high surface area but lacking the reinforcing fiber structure found in composites. The distinct composition and microstructure result in carbon composites being ideal for lightweight, high-strength applications, while carbon black is mainly used as a pigment or reinforcing filler in rubber and plastics.

Manufacturing Processes: A Comparative Overview

Carbon composite manufacturing involves layering carbon fibers with resin matrix through processes like autoclave curing or resin transfer molding, resulting in lightweight, high-strength materials widely used in aerospace and automotive industries. In contrast, carbon black is produced by the incomplete combustion of heavy petroleum products during furnace black or thermal black processes, mainly utilized as a reinforcing filler in rubber and plastics. The precision and complexity of composite fabrication emphasize structural performance, whereas carbon black production prioritizes cost-efficiency and particle size control for pigment and reinforcement applications.

Mechanical Properties and Performance

Carbon composite materials exhibit superior mechanical properties compared to carbon black, offering high tensile strength, stiffness, and lightweight performance ideal for aerospace and automotive applications. Carbon composites provide enhanced fatigue resistance and impact durability, outperforming carbon black, which primarily serves as a reinforcing filler with lower structural integrity. The advanced fiber-matrix architecture in carbon composites enables tailored mechanical performance, making them essential for high-performance and load-bearing components.

Applications in Industry: Where Each Excels

Carbon composites dominate aerospace and automotive industries due to their lightweight strength and corrosion resistance, enhancing fuel efficiency and structural integrity. Carbon black excels in rubber manufacturing and pigment applications, improving tire durability, UV protection, and electrical conductivity in plastics and inks. Each material caters to specific industrial needs, with composites optimizing performance in structural uses and carbon black enhancing material properties in consumer and industrial products.

Cost Analysis: Carbon Composite vs Carbon Black

Carbon composite materials generally incur higher initial costs due to complex manufacturing processes and expensive raw materials, while carbon black offers a more economical option as a widely produced and less costly additive. Carbon composites provide superior strength-to-weight ratios, which can justify their higher expense in high-performance applications, but for budget-sensitive projects, carbon black remains preferable because of its lower price point and widespread availability. The cost analysis reveals that carbon composite investments yield long-term benefits through enhanced durability and reduced maintenance, whereas carbon black favors immediate cost savings and mass-production efficiency.

Environmental Impact and Sustainability

Carbon composites offer superior sustainability through their lightweight properties, reducing fuel consumption and greenhouse gas emissions in automotive and aerospace applications compared to conventional materials. Carbon black, primarily derived from fossil fuels, poses environmental challenges due to its production process, which emits significant air pollutants and contributes to particulate matter pollution. The recyclability of carbon composites is improving with advanced technologies, while carbon black remains less sustainable due to its non-renewable origins and limited recyclability options.

Durability and Longevity in Real-World Use

Carbon composite materials exhibit superior durability and longevity in real-world applications compared to carbon black, owing to their engineered fiber-reinforced structure that resists wear, fatigue, and environmental degradation. Carbon black primarily serves as a reinforcing filler within rubber and plastic compounds, enhancing tensile strength but lacking the structural integrity of composites. In high-stress environments such as aerospace, automotive, and sports equipment, carbon composites maintain performance over extended periods, reducing maintenance and replacement costs.

Recent Innovations and Technological Advancements

Recent innovations in carbon composites have focused on enhancing mechanical strength and reducing weight through advanced resin matrices and 3D weaving techniques, significantly benefiting aerospace and automotive industries. Carbon black technology has seen breakthroughs in surface modification and nano-dispersion, improving conductivity and reinforcing elastomers for tire manufacturing and electronics. Cutting-edge research integrates carbon composites with carbon black nanoparticles to create hybrid materials that optimize durability and electrical performance in energy storage devices.

Choosing the Right Material: Key Considerations

Choosing the right carbon material depends on the application's mechanical strength, conductivity, and cost requirements. Carbon composites offer superior strength-to-weight ratios and are ideal for aerospace and automotive industries, while carbon black excels in enhancing electrical conductivity and reinforcing rubber products. Evaluating performance needs alongside environmental impact and durability ensures optimal material selection for specific industrial applications.

Carbon composite vs Carbon black Infographic

materialdif.com

materialdif.com