Carbon composites offer superior strength-to-weight ratios compared to carbon steel, making them ideal for aerospace and automotive applications. Unlike carbon steel, carbon composites resist corrosion and fatigue, providing longer material lifespan and reduced maintenance costs. Manufacturing processes for carbon composites are more complex, but the enhanced performance often justifies the investment in critical, high-performance components.

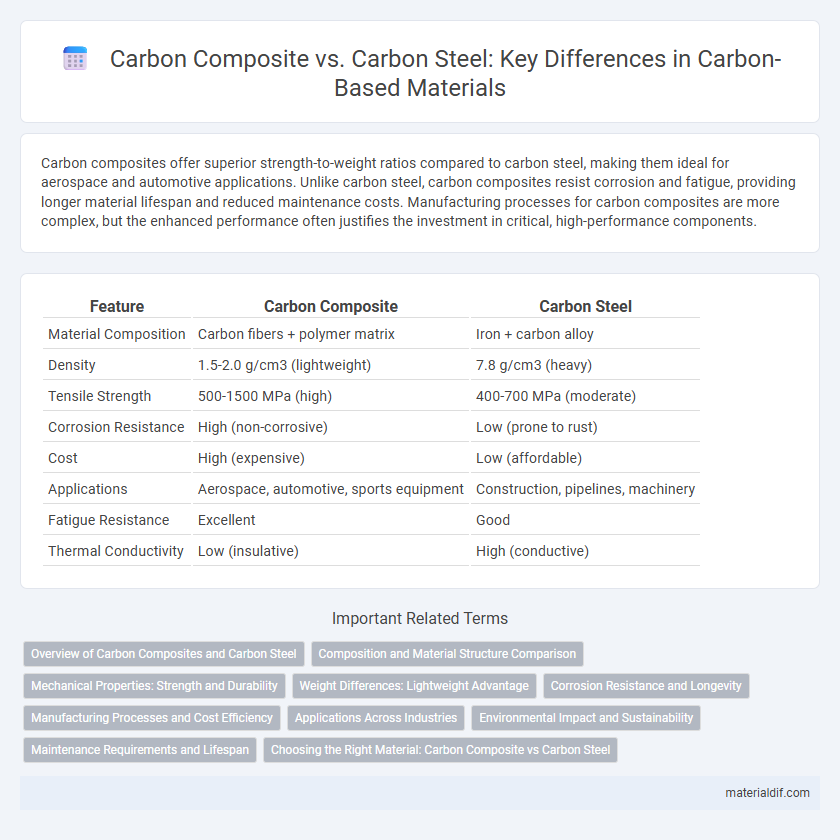

Table of Comparison

| Feature | Carbon Composite | Carbon Steel |

|---|---|---|

| Material Composition | Carbon fibers + polymer matrix | Iron + carbon alloy |

| Density | 1.5-2.0 g/cm3 (lightweight) | 7.8 g/cm3 (heavy) |

| Tensile Strength | 500-1500 MPa (high) | 400-700 MPa (moderate) |

| Corrosion Resistance | High (non-corrosive) | Low (prone to rust) |

| Cost | High (expensive) | Low (affordable) |

| Applications | Aerospace, automotive, sports equipment | Construction, pipelines, machinery |

| Fatigue Resistance | Excellent | Good |

| Thermal Conductivity | Low (insulative) | High (conductive) |

Overview of Carbon Composites and Carbon Steel

Carbon composites are engineered materials composed of carbon fibers embedded within a polymer matrix, offering exceptional strength-to-weight ratios and corrosion resistance. Carbon steel, an alloy primarily composed of iron and carbon, provides high tensile strength and durability but is prone to rust without protective coatings. The choice between carbon composites and carbon steel depends on application requirements such as weight constraints, mechanical performance, and environmental exposure.

Composition and Material Structure Comparison

Carbon composite consists of carbon fibers embedded in a polymer matrix, offering high strength-to-weight ratio and excellent corrosion resistance, while carbon steel is an alloy primarily composed of iron and carbon with a crystalline microstructure that provides durability and tensile strength. The molecular structure of carbon composites features aligned carbon fibers creating anisotropic properties optimized for specific load directions, contrasting with the isotropic grain structure of carbon steel formed through controlled cooling and heat treatments. This difference in composition and material structure results in carbon composites being lighter and more resistant to fatigue, whereas carbon steel exhibits superior impact resistance and machinability.

Mechanical Properties: Strength and Durability

Carbon composites exhibit superior strength-to-weight ratios and enhanced fatigue resistance compared to carbon steel, making them ideal for high-performance applications. Carbon steel, while generally less strong by weight, offers excellent toughness and can withstand higher impact forces, contributing to its durability in structural uses. The mechanical properties of carbon composites allow for tailored strength and stiffness, whereas carbon steel provides uniform mechanical performance with well-understood failure modes.

Weight Differences: Lightweight Advantage

Carbon composites offer a significant weight advantage over carbon steel, with densities typically ranging from 1.5 to 2 g/cm3 compared to carbon steel's 7.85 g/cm3. This reduction in weight translates to enhanced fuel efficiency and improved performance in automotive and aerospace applications. The lightweight nature of carbon composites makes them ideal for structures requiring high strength-to-weight ratios, outperforming carbon steel in weight-sensitive designs.

Corrosion Resistance and Longevity

Carbon composites exhibit superior corrosion resistance compared to carbon steel due to their synthetic fiber matrix, which is inert to moisture and chemicals. This enhanced corrosion resistance significantly extends the longevity of carbon composites in harsh environmental conditions where carbon steel often suffers from rust and degradation. Consequently, carbon composites are favored in applications requiring durable, long-lasting materials with minimal maintenance.

Manufacturing Processes and Cost Efficiency

Carbon composite manufacturing involves layering carbon fibers with resin through processes like resin transfer molding and autoclave curing, leading to lightweight, high-strength components with higher initial production costs. Carbon steel is produced via traditional methods including casting, rolling, and forging, offering lower material and processing expenses but with increased weight and lower strength-to-weight ratios. Cost efficiency varies as carbon composites reduce long-term maintenance and fuel consumption in applications like aerospace, while carbon steel excels in budget-sensitive construction projects due to its affordability and ease of fabrication.

Applications Across Industries

Carbon composites excel in aerospace, automotive, and sporting goods industries due to their high strength-to-weight ratio and corrosion resistance, enabling lightweight and fuel-efficient designs. Carbon steel remains dominant in construction, pipelines, and heavy machinery for its robustness, cost-effectiveness, and ease of fabrication. Industrial applications favor carbon composites for performance-critical components, while carbon steel is preferred for structural frameworks and infrastructure development.

Environmental Impact and Sustainability

Carbon composites offer superior strength-to-weight ratios compared to carbon steel, significantly reducing fuel consumption and greenhouse gas emissions in transportation applications. Unlike carbon steel, carbon composites are corrosion-resistant, leading to longer product lifespans and less frequent replacements, which minimizes waste and resource extraction. However, carbon composite recycling remains challenging, necessitating advancements in sustainable end-of-life processing to fully leverage their environmental benefits over carbon steel.

Maintenance Requirements and Lifespan

Carbon composites require minimal maintenance due to their corrosion resistance and durability, significantly outlasting carbon steel in harsh environments. Carbon steel, prone to rust and corrosion, demands regular inspections, coatings, and repairs to prevent structural degradation. The extended lifespan of carbon composites reduces overall lifecycle costs, making them preferable for long-term applications where maintenance accessibility is limited.

Choosing the Right Material: Carbon Composite vs Carbon Steel

Carbon composites offer superior strength-to-weight ratios and corrosion resistance, making them ideal for aerospace and automotive applications where durability and lightness are critical. Carbon steel provides excellent tensile strength and cost-effectiveness, widely used in construction, manufacturing, and infrastructure projects demanding high load-bearing capacity. Selecting between carbon composite and carbon steel depends on factors like mechanical performance requirements, environmental exposure, and budget constraints.

Carbon composite vs Carbon steel Infographic

materialdif.com

materialdif.com