Multi-walled carbon nanotubes (MWCNTs) consist of multiple concentric graphene cylinders, offering enhanced mechanical strength and higher electrical conductivity compared to single-walled carbon nanotubes (SWCNTs). SWCNTs provide superior electron transport properties and greater flexibility due to their single graphene layer structure, making them ideal for nanoscale electronic applications. Understanding the fundamental differences in structure and properties between MWCNTs and SWCNTs is crucial for optimizing their use in carbon-based nanocomposites and electronic devices.

Table of Comparison

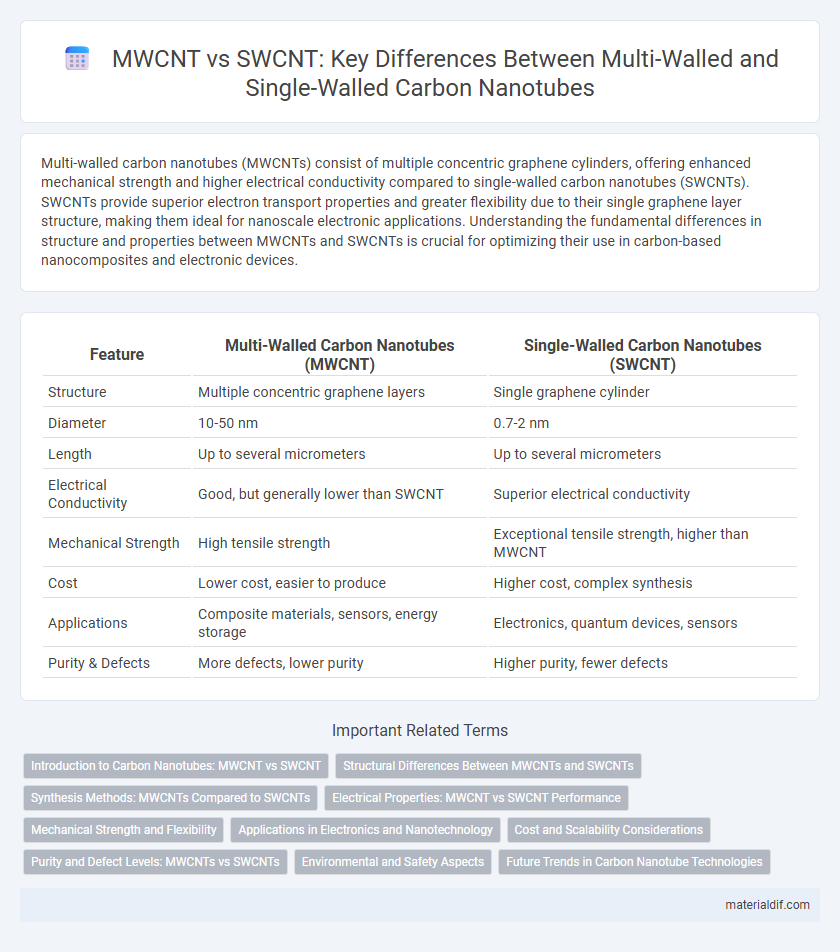

| Feature | Multi-Walled Carbon Nanotubes (MWCNT) | Single-Walled Carbon Nanotubes (SWCNT) |

|---|---|---|

| Structure | Multiple concentric graphene layers | Single graphene cylinder |

| Diameter | 10-50 nm | 0.7-2 nm |

| Length | Up to several micrometers | Up to several micrometers |

| Electrical Conductivity | Good, but generally lower than SWCNT | Superior electrical conductivity |

| Mechanical Strength | High tensile strength | Exceptional tensile strength, higher than MWCNT |

| Cost | Lower cost, easier to produce | Higher cost, complex synthesis |

| Applications | Composite materials, sensors, energy storage | Electronics, quantum devices, sensors |

| Purity & Defects | More defects, lower purity | Higher purity, fewer defects |

Introduction to Carbon Nanotubes: MWCNT vs SWCNT

Carbon nanotubes (CNTs) are cylindrical nanostructures composed of graphene sheets rolled into tubes, categorized into multi-walled carbon nanotubes (MWCNTs) and single-walled carbon nanotubes (SWCNTs). MWCNTs consist of multiple concentric graphene layers, offering superior mechanical strength and thermal conductivity, while SWCNTs feature a single graphene layer, providing exceptional electrical conductivity and quantum properties. These differences influence their applications in fields such as electronics, composites, and nanotechnology, making the choice between MWCNTs and SWCNTs critical for targeted performance.

Structural Differences Between MWCNTs and SWCNTs

Multi-Walled Carbon Nanotubes (MWCNTs) consist of multiple concentric graphene cylinders with interlayer spacing of approximately 0.34 nm, providing enhanced mechanical strength and electrical conductivity. Single-Walled Carbon Nanotubes (SWCNTs) are composed of a single graphene sheet rolled into a cylindrical structure with diameters typically ranging from 0.7 to 2 nm, resulting in unique electronic properties and higher surface area. The structural distinction between MWCNTs and SWCNTs significantly influences their applications in nanotechnology, electronics, and composite materials.

Synthesis Methods: MWCNTs Compared to SWCNTs

Multi-walled carbon nanotubes (MWCNTs) are predominantly synthesized using chemical vapor deposition (CVD), arc discharge, and laser ablation, with CVD offering greater scalability and cost-efficiency for industrial applications. Single-walled carbon nanotubes (SWCNTs) require more precise control during synthesis, often relying on arc discharge and laser ablation to produce high-purity tubes with uniform diameter and chirality. The complexity and energy demands of SWCNT synthesis limit large-scale production compared to MWCNT's relatively straightforward and robust methods.

Electrical Properties: MWCNT vs SWCNT Performance

Multi-walled carbon nanotubes (MWCNTs) exhibit higher electrical conductivity due to multiple concentric graphene layers facilitating electron transport, whereas single-walled carbon nanotubes (SWCNTs) possess superior intrinsic electron mobility and ballistic transport over longer distances. SWCNTs display distinct semiconducting or metallic behavior depending on chirality, enabling precise tuning of electrical properties, while MWCNTs generally show metallic characteristics with less variability. Consequently, SWCNTs outperform MWCNTs in applications requiring high-frequency response and nanoscale transistors, whereas MWCNTs are preferred for robust conductive composites and energy storage devices due to enhanced current-carrying capacity.

Mechanical Strength and Flexibility

Multi-Walled Carbon Nanotubes (MWCNTs) exhibit superior mechanical strength due to their multiple concentric graphene layers, providing enhanced load-bearing capacity and resistance to deformation. Single-Walled Carbon Nanotubes (SWCNTs), while slightly less robust in tensile strength, offer greater flexibility and elasticity because of their single graphene cylinder structure. The interplay between strength and flexibility makes MWCNTs ideal for applications requiring durability and SWCNTs preferable for devices needing high bendability.

Applications in Electronics and Nanotechnology

Multi-walled carbon nanotubes (MWCNTs) offer enhanced mechanical strength and electrical conductivity, making them ideal for flexible electronics and electromagnetic interference shielding. Single-walled carbon nanotubes (SWCNTs) provide superior electrical properties and high electron mobility, key for high-performance transistors, sensors, and nanoscale electronic devices. Both types are integral in advancing nanotechnology applications, with MWCNTs favored for robustness and SWCNTs for precision electronic functionality.

Cost and Scalability Considerations

Multi-walled carbon nanotubes (MWCNTs) offer significant advantages in cost-effectiveness and scalability compared to single-walled carbon nanotubes (SWCNTs) due to simpler synthesis methods and higher yields. MWCNT production uses chemical vapor deposition (CVD) techniques that are more mature and industrially scalable, reducing overall manufacturing expenses. SWCNTs, while exhibiting superior electrical and mechanical properties, require more complex, time-consuming, and expensive methods, limiting their large-scale commercial applications.

Purity and Defect Levels: MWCNTs vs SWCNTs

Multi-walled carbon nanotubes (MWCNTs) typically exhibit lower purity levels and higher defect densities compared to single-walled carbon nanotubes (SWCNTs), impacting their electrical and mechanical properties. SWCNTs often achieve higher structural perfection due to improved synthesis techniques like chemical vapor deposition, resulting in fewer defects and superior conductivity. Controlling defect levels in MWCNTs remains challenging, as their multiple concentric graphene layers increase the likelihood of structural imperfections.

Environmental and Safety Aspects

Multi-walled carbon nanotubes (MWCNTs) and single-walled carbon nanotubes (SWCNTs) differ significantly in environmental impact and safety profiles due to their structural variations. MWCNTs pose higher risks of respiratory exposure and potential toxicity linked to their larger size and greater biopersistence, leading to increased concerns in occupational settings. SWCNTs, while potentially more reactive, tend to disperse more easily and may degrade faster, reducing long-term environmental accumulation but still requiring stringent handling protocols to mitigate inhalation hazards.

Future Trends in Carbon Nanotube Technologies

Future trends in carbon nanotube technologies highlight the increasing utilization of MWCNTs (Multi-Walled Carbon Nanotubes) due to their superior mechanical strength and cost-effective production compared to SWCNTs (Single-Walled Carbon Nanotubes). Research is advancing toward enhancing the electronic and thermal properties of SWCNTs for applications in high-performance electronics and energy storage. Integration of hybrid CNT structures promises breakthroughs in flexible electronics, sensors, and nanocomposites, driving innovation in various industrial sectors.

MWCNT vs SWCNT Infographic

materialdif.com

materialdif.com