Carbon aerogels exhibit a highly porous, lightweight structure with exceptional electrical conductivity, making them ideal for advanced energy storage and catalysis applications. In contrast, carbon xerogels, formed through ambient drying, possess a denser network with lower surface area but offer enhanced mechanical strength and easier scalability for industrial uses. Both materials demonstrate unique advantages dependent on the specific requirements of electrochemical performance and structural integrity.

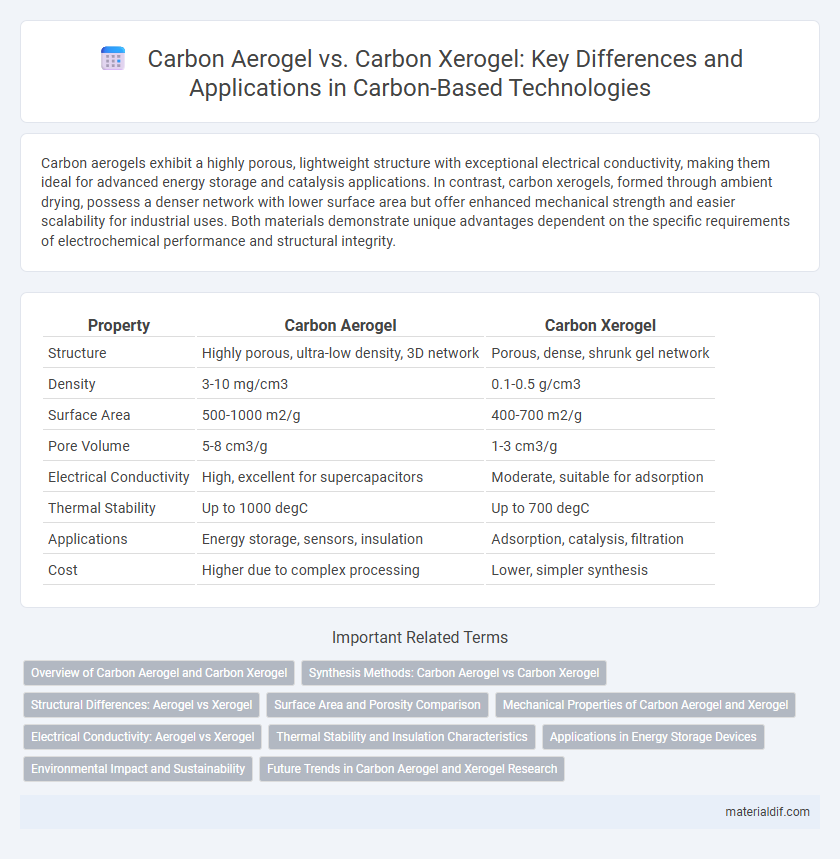

Table of Comparison

| Property | Carbon Aerogel | Carbon Xerogel |

|---|---|---|

| Structure | Highly porous, ultra-low density, 3D network | Porous, dense, shrunk gel network |

| Density | 3-10 mg/cm3 | 0.1-0.5 g/cm3 |

| Surface Area | 500-1000 m2/g | 400-700 m2/g |

| Pore Volume | 5-8 cm3/g | 1-3 cm3/g |

| Electrical Conductivity | High, excellent for supercapacitors | Moderate, suitable for adsorption |

| Thermal Stability | Up to 1000 degC | Up to 700 degC |

| Applications | Energy storage, sensors, insulation | Adsorption, catalysis, filtration |

| Cost | Higher due to complex processing | Lower, simpler synthesis |

Overview of Carbon Aerogel and Carbon Xerogel

Carbon aerogels are highly porous, ultralight materials with a three-dimensional network structure composed of carbon nanoparticles, renowned for their low density and exceptional surface area beneficial for energy storage and insulation. Carbon xerogels, derived through ambient pressure drying, have a denser and less porous structure compared to aerogels but maintain high electrical conductivity and mechanical strength ideal for catalyst supports and electrodes. Both materials exhibit unique microstructures influencing their specific surface area, pore size distribution, and resultant applications in supercapacitors, adsorption, and environmental remediation.

Synthesis Methods: Carbon Aerogel vs Carbon Xerogel

Carbon aerogels are typically synthesized through a sol-gel process followed by supercritical drying, which preserves the porous structure and results in a lightweight, high-surface-area material. In contrast, carbon xerogels are produced by ambient pressure drying of the gel, often leading to higher shrinkage and denser material with reduced porosity. These differences in drying techniques significantly influence the microstructure and performance characteristics of carbon aerogels and xerogels in applications such as energy storage and catalysis.

Structural Differences: Aerogel vs Xerogel

Carbon aerogels possess an ultralight, highly porous structure composed of interconnected nanoscale particles forming a three-dimensional network with large mesopores and macropores. In contrast, carbon xerogels exhibit a denser, more compact matrix with smaller pore sizes and lower porosity due to shrinkage during drying processes. The structural disparity results in carbon aerogels having superior surface area and lower density compared to the rigid, less porous architecture of carbon xerogels.

Surface Area and Porosity Comparison

Carbon aerogels exhibit significantly higher surface area, often exceeding 600 m2/g, compared to carbon xerogels, which typically range between 300-500 m2/g. The porosity of carbon aerogels is predominantly mesoporous with interconnected nanopores enhancing mass transport, while carbon xerogels possess a more heterogeneous pore distribution with lower pore volume and fewer mesopores. This structural difference results in carbon aerogels having superior adsorption capabilities and electrochemical performance in applications such as supercapacitors and catalysis.

Mechanical Properties of Carbon Aerogel and Xerogel

Carbon aerogels exhibit remarkable mechanical properties such as high compressive strength and excellent elasticity due to their highly porous, interconnected nanostructure. In contrast, carbon xerogels typically possess denser, less porous frameworks, resulting in greater brittleness and lower mechanical flexibility. The unique mesoporous architecture of carbon aerogels allows for superior resilience and durability under mechanical stress compared to the rigid morphology of carbon xerogels.

Electrical Conductivity: Aerogel vs Xerogel

Carbon aerogels exhibit higher electrical conductivity compared to carbon xerogels due to their more porous and interconnected nanostructure, which facilitates efficient electron transport. The low density and high surface area of carbon aerogels enhance charge carrier mobility, making them superior in applications requiring rapid electrical response. In contrast, carbon xerogels possess a denser, less porous framework that limits conductivity, resulting in slower electron flow and reduced performance in electrochemical devices.

Thermal Stability and Insulation Characteristics

Carbon aerogels exhibit superior thermal stability compared to carbon xerogels, maintaining structural integrity at temperatures exceeding 1,200degC due to their highly porous and interconnected nanostructure. Their unique low density and large specific surface area result in exceptional insulation properties, with thermal conductivity values as low as 0.02 W/m*K. In contrast, carbon xerogels possess less porosity and denser morphology, leading to higher thermal conductivity and reduced thermal stability under prolonged high-temperature exposure.

Applications in Energy Storage Devices

Carbon aerogels exhibit high porosity and low density, making them ideal for supercapacitors with rapid charge-discharge cycles and enhanced energy density. Carbon xerogels offer a more controlled pore structure and higher mechanical strength, suitable for electrode materials in lithium-ion batteries to improve cycle stability and capacity retention. Both materials optimize ion transport and conductivity but are selected based on specific energy storage requirements such as power density and structural integrity.

Environmental Impact and Sustainability

Carbon aerogels exhibit lower environmental impact compared to carbon xerogels due to their higher porosity and enhanced adsorption capabilities, which contribute to superior pollutant capture and energy efficiency in applications. The sustainable synthesis of carbon aerogels often involves biobased precursors and low-energy drying methods such as supercritical CO2 drying, reducing carbon footprint relative to the ambient pressure drying used for carbon xerogels. Lifecycle assessments highlight carbon aerogels' potential for reduced greenhouse gas emissions and waste generation, promoting their use in eco-friendly energy storage, water purification, and environmental remediation technologies.

Future Trends in Carbon Aerogel and Xerogel Research

Future trends in carbon aerogel and xerogel research emphasize enhancing their electrical conductivity and mechanical strength for energy storage and environmental applications. Innovations in pore structure control and surface functionalization aim to improve adsorption capacity and catalytic performance. Integration with nanomaterials and sustainable synthesis methods is driving advancements toward scalable production and multifunctional applications.

Carbon Aerogel vs Carbon Xerogel Infographic

materialdif.com

materialdif.com