Carbon fiber weave consists of fibers interlaced in a structured, grid-like pattern, providing superior strength, stiffness, and durability ideal for high-performance applications such as aerospace and automotive components. Carbon fiber nonwoven features randomly oriented fibers bonded together, offering flexibility, better impact resistance, and ease of molding into complex shapes, making it suitable for lightweight and shock-absorbing materials. The choice between woven and nonwoven carbon fiber depends on the specific mechanical properties and manufacturing requirements of the intended use.

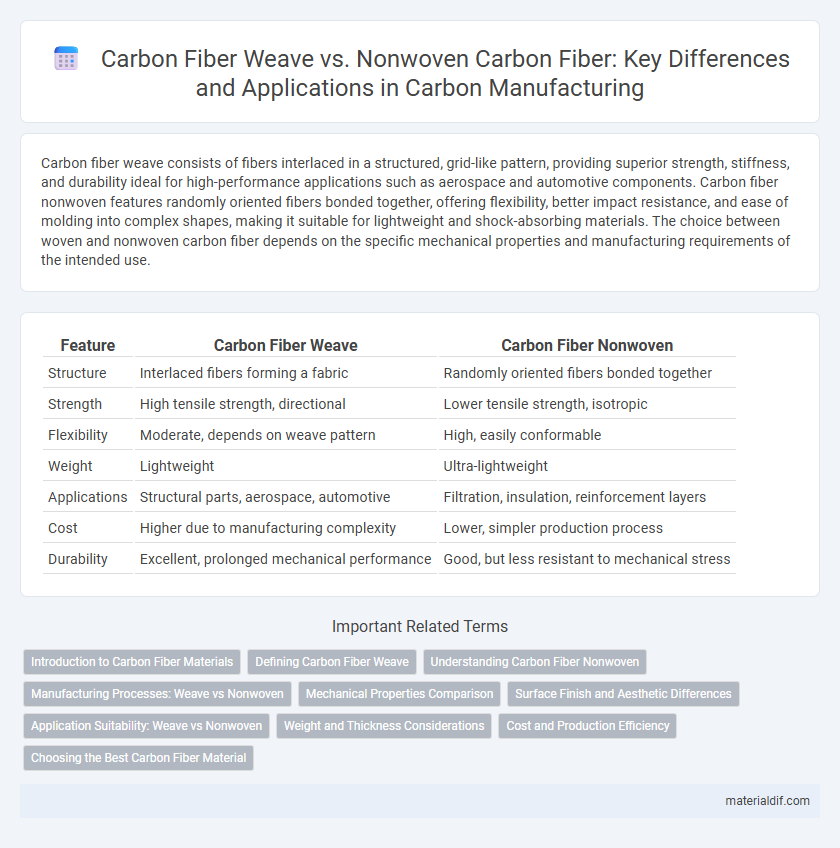

Table of Comparison

| Feature | Carbon Fiber Weave | Carbon Fiber Nonwoven |

|---|---|---|

| Structure | Interlaced fibers forming a fabric | Randomly oriented fibers bonded together |

| Strength | High tensile strength, directional | Lower tensile strength, isotropic |

| Flexibility | Moderate, depends on weave pattern | High, easily conformable |

| Weight | Lightweight | Ultra-lightweight |

| Applications | Structural parts, aerospace, automotive | Filtration, insulation, reinforcement layers |

| Cost | Higher due to manufacturing complexity | Lower, simpler production process |

| Durability | Excellent, prolonged mechanical performance | Good, but less resistant to mechanical stress |

Introduction to Carbon Fiber Materials

Carbon fiber weave consists of interlaced strands forming a patterned fabric that offers enhanced strength and stiffness, ideal for structural applications requiring uniform load distribution. Nonwoven carbon fiber materials are composed of randomly oriented fibers bonded together, providing superior impact absorption and flexibility for composite layering. These material formats differ significantly in mechanical properties and manufacturing processes, influencing performance outcomes in aerospace, automotive, and sporting goods industries.

Defining Carbon Fiber Weave

Carbon fiber weave refers to the structured interlacing of carbon fibers into a fabric pattern, enhancing strength and flexibility in composite materials. This woven construction maximizes load distribution and provides superior tensile strength compared to nonwoven carbon fibers, which are randomly oriented and lack defined patterns. The distinct weave patterns, such as twill or plain weave, significantly influence the mechanical properties and aesthetic qualities of carbon fiber composites.

Understanding Carbon Fiber Nonwoven

Carbon fiber nonwoven materials consist of randomly oriented fibers bonded together, offering enhanced toughness and flexibility compared to the structured pattern of carbon fiber weave. Nonwoven carbon fiber excels in applications requiring complex shapes and impact resistance due to its isotropic mechanical properties and reduced delamination risk. Its manufacturing process allows for faster production and customization, making it ideal for automotive, aerospace, and sporting goods where tailored performance is essential.

Manufacturing Processes: Weave vs Nonwoven

Carbon fiber weave manufacturing involves interlacing continuous carbon filament threads in a specific pattern, resulting in a strong and durable fabric with high tensile strength and excellent dimensional stability. The nonwoven carbon fiber process uses bonded or matted short carbon fibers, created through methods like needle punching or resin bonding, producing a more flexible and less structured material suitable for applications requiring conformability. Weave processes require precision looms and controlled tension to ensure consistent fiber alignment, while nonwoven production emphasizes fiber distribution and bonding techniques to achieve uniformity and desired mechanical properties.

Mechanical Properties Comparison

Carbon fiber weave exhibits superior tensile strength and stiffness due to its organized interlacing structure, which distributes stress evenly across the fabric. Nonwoven carbon fiber, while offering improved conformability and impact resistance, generally shows lower mechanical strength and reduced load-bearing capacity. The woven variant is preferred in aerospace and automotive industries where high mechanical performance is critical, whereas nonwoven materials are often used in applications requiring flexibility and energy absorption.

Surface Finish and Aesthetic Differences

Carbon fiber weave offers a glossy, patterned surface finish characterized by the distinct interlacing of fibers that enhances visual appeal and texture uniformity. In contrast, carbon fiber nonwoven exhibits a matte, random fiber orientation resulting in a rougher, less uniform surface that emphasizes functional over aesthetic qualities. The woven variant is preferred for applications where a premium, polished look is critical, while nonwoven is favored for structural uses requiring less visual emphasis.

Application Suitability: Weave vs Nonwoven

Carbon fiber weave offers superior tensile strength and stiffness, making it ideal for aerospace, automotive, and sporting goods where structural integrity is critical. Nonwoven carbon fiber provides enhanced impact resistance and flexibility, suitable for applications like thermal insulation, filtration, and lightweight composites requiring energy absorption. Selecting between woven and nonwoven carbon fiber depends on performance requirements such as load-bearing capacity, durability, and design complexity.

Weight and Thickness Considerations

Carbon fiber weave offers superior strength and stiffness with a consistent thickness typically ranging from 0.2 to 0.5 mm, while maintaining lightweight properties ideal for aerospace and automotive applications. Nonwoven carbon fiber mats are generally thicker, around 0.5 to 2 mm, and heavier due to randomly oriented fibers that provide impact resistance rather than directional strength. Selecting between woven and nonwoven carbon fibers depends on balancing weight constraints with required mechanical performance and thickness tolerances.

Cost and Production Efficiency

Carbon fiber weave typically incurs higher costs due to the intricate interlacing process and longer production times, but it offers superior strength and stiffness for advanced structural applications. Nonwoven carbon fiber mats are generally more cost-effective and enable faster production cycles, making them suitable for large-scale, less structurally demanding components. The selection between woven and nonwoven carbon fiber depends largely on balancing budget constraints with performance requirements in manufacturing.

Choosing the Best Carbon Fiber Material

Selecting the best carbon fiber material depends on the specific application demands, with woven carbon fiber offering superior strength and stiffness due to its interlaced structure, providing excellent load distribution in aerospace and automotive components. Nonwoven carbon fiber, characterized by randomly oriented fibers, excels in impact resistance and flexibility, making it ideal for complex shapes and composite reinforcement where directional strength is less critical. Evaluating factors such as mechanical performance, weight constraints, and manufacturing processes is essential to optimize the benefits of either carbon fiber weave or nonwoven materials.

Carbon fiber weave vs Carbon fiber nonwoven Infographic

materialdif.com

materialdif.com