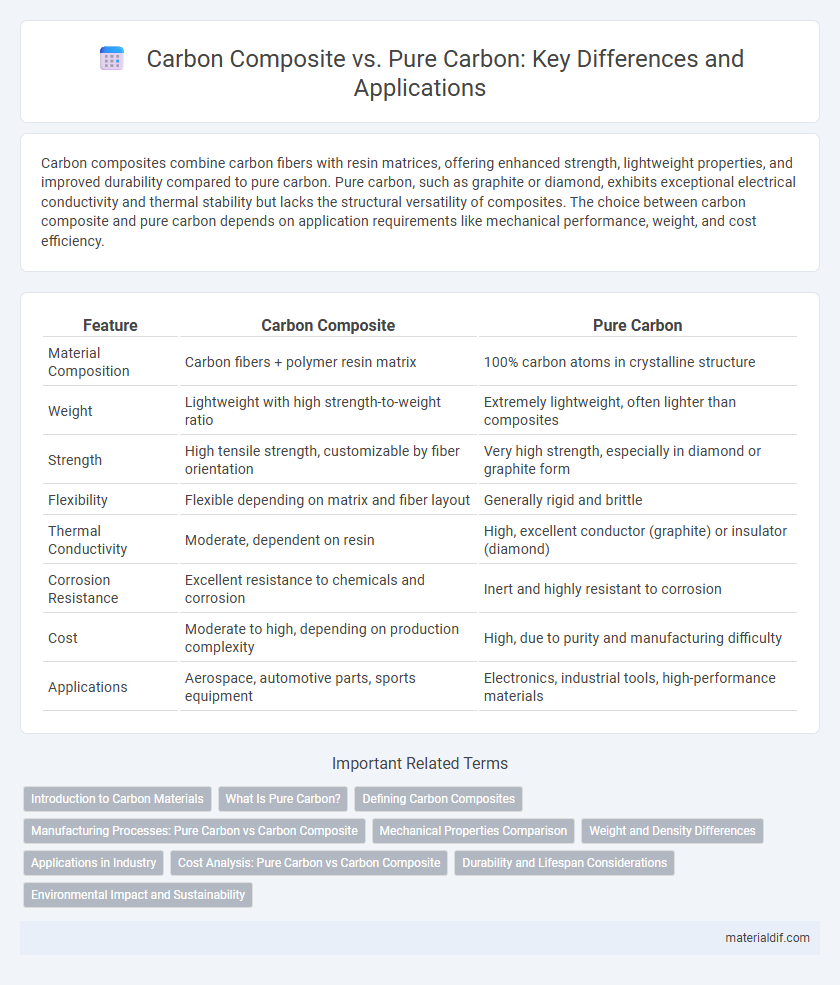

Carbon composites combine carbon fibers with resin matrices, offering enhanced strength, lightweight properties, and improved durability compared to pure carbon. Pure carbon, such as graphite or diamond, exhibits exceptional electrical conductivity and thermal stability but lacks the structural versatility of composites. The choice between carbon composite and pure carbon depends on application requirements like mechanical performance, weight, and cost efficiency.

Table of Comparison

| Feature | Carbon Composite | Pure Carbon |

|---|---|---|

| Material Composition | Carbon fibers + polymer resin matrix | 100% carbon atoms in crystalline structure |

| Weight | Lightweight with high strength-to-weight ratio | Extremely lightweight, often lighter than composites |

| Strength | High tensile strength, customizable by fiber orientation | Very high strength, especially in diamond or graphite form |

| Flexibility | Flexible depending on matrix and fiber layout | Generally rigid and brittle |

| Thermal Conductivity | Moderate, dependent on resin | High, excellent conductor (graphite) or insulator (diamond) |

| Corrosion Resistance | Excellent resistance to chemicals and corrosion | Inert and highly resistant to corrosion |

| Cost | Moderate to high, depending on production complexity | High, due to purity and manufacturing difficulty |

| Applications | Aerospace, automotive parts, sports equipment | Electronics, industrial tools, high-performance materials |

Introduction to Carbon Materials

Carbon composites combine carbon fibers with polymer, ceramic, or metal matrices to enhance strength, stiffness, and lightweight properties in aerospace, automotive, and sports applications. Pure carbon materials, such as graphite and diamond, consist solely of carbon atoms arranged in specific crystalline structures, providing exceptional conductivity, hardness, and thermal resistance. Understanding the differences between carbon composites and pure carbon is crucial for selecting materials based on mechanical performance, durability, and application-specific requirements.

What Is Pure Carbon?

Pure carbon consists entirely of carbon atoms arranged in a specific crystalline structure, such as graphite or diamond, without any additional elements or compounds. Unlike carbon composites, which combine carbon fibers with resins or other materials to enhance strength and flexibility, pure carbon exhibits distinct electrical conductivity, chemical stability, and high thermal resistance. This fundamental form of carbon serves as the basis for various industrial applications, including electrodes, lubricants, and high-performance materials.

Defining Carbon Composites

Carbon composites consist of carbon fibers embedded within a resin matrix, combining high strength and lightweight properties ideal for aerospace and automotive applications. Pure carbon, in contrast, refers to materials composed entirely of carbon atoms, such as graphite or diamond, with distinct crystalline structures and separate mechanical characteristics. The unique synergy in carbon composites enhances durability and flexibility beyond what pure carbon materials typically offer.

Manufacturing Processes: Pure Carbon vs Carbon Composite

Pure carbon typically undergoes processes such as chemical vapor deposition and high-temperature purification to achieve a highly crystalline structure, enhancing its electrical conductivity and thermal properties. Carbon composites combine carbon fibers with polymer matrices through techniques like lay-up, molding, and curing, enabling tailored mechanical strength and weight optimization. Manufacturing carbon composites allows for greater design flexibility and structural performance compared to pure carbon, which is limited by its brittle nature and processing constraints.

Mechanical Properties Comparison

Carbon composites exhibit superior mechanical properties compared to pure carbon due to their enhanced strength-to-weight ratio and improved stiffness. The integration of carbon fibers within a polymer matrix significantly increases tensile strength and impact resistance, making them ideal for aerospace and automotive applications. Pure carbon, although strong in compression, tends to be brittle and lacks the flexibility and durability found in carbon composite materials.

Weight and Density Differences

Carbon composites combine carbon fibers with a resin matrix, resulting in a material significantly lighter than pure carbon but with slightly higher density due to the resin content. Pure carbon, often found in forms like graphite or diamond, has a uniform, dense atomic structure that leads to higher density and greater weight compared to carbon composites. The lower weight-to-strength ratio of carbon composites makes them ideal for aerospace and automotive applications requiring lightweight yet strong materials.

Applications in Industry

Carbon composites offer enhanced strength-to-weight ratios and corrosion resistance, making them ideal for aerospace, automotive, and sports equipment industries where durability and lightweight materials are critical. Pure carbon, often found in graphite form, excels in electrical conductivity and high-temperature stability, thus it is widely used in electrical electrodes, batteries, and industrial furnaces. Industrial applications prioritize carbon composites for structural components and pure carbon for energy and thermal management solutions.

Cost Analysis: Pure Carbon vs Carbon Composite

Carbon composites generally offer superior strength-to-weight ratios compared to pure carbon, but they come at higher production costs due to complex manufacturing processes involving resin and fiber layering. Pure carbon, while less expensive, lacks the enhanced mechanical properties found in composites, making it suitable for applications with lower performance demands but tighter budgets. Cost analysis reveals that carbon composites, despite their upfront investment, provide long-term value through durability and reduced maintenance costs.

Durability and Lifespan Considerations

Carbon composites offer enhanced durability and longer lifespan compared to pure carbon due to their layered structure, which provides greater resistance to impact, fatigue, and environmental factors. Pure carbon materials, while strong and lightweight, are more prone to brittleness and wear under mechanical stress, limiting their practical longevity. The integration of resin matrices in carbon composites further improves toughness and corrosion resistance, making them ideal for high-performance applications requiring sustained durability.

Environmental Impact and Sustainability

Carbon composites, combining carbon fibers with polymers, offer enhanced strength-to-weight ratios but pose challenges in recyclability due to mixed materials. Pure carbon materials, such as graphite or activated carbon, generally have lower environmental footprints in production and can be more easily recycled or repurposed, contributing to sustainability. The energy-intensive manufacturing of carbon composites and difficulties in end-of-life processing highlight the need for advancements in eco-friendly recycling technologies to mitigate environmental impact.

Carbon Composite vs Pure Carbon Infographic

materialdif.com

materialdif.com