Carbon composite materials offer superior toughness and flexibility compared to carbon ceramic counterparts, making them ideal for lightweight structural applications. Carbon ceramics excel in high-temperature resistance and wear durability, which suits them well for braking systems and thermal insulation. Selecting between carbon composite and carbon ceramic depends on the specific requirements of strength, heat resistance, and weight optimization in the intended use.

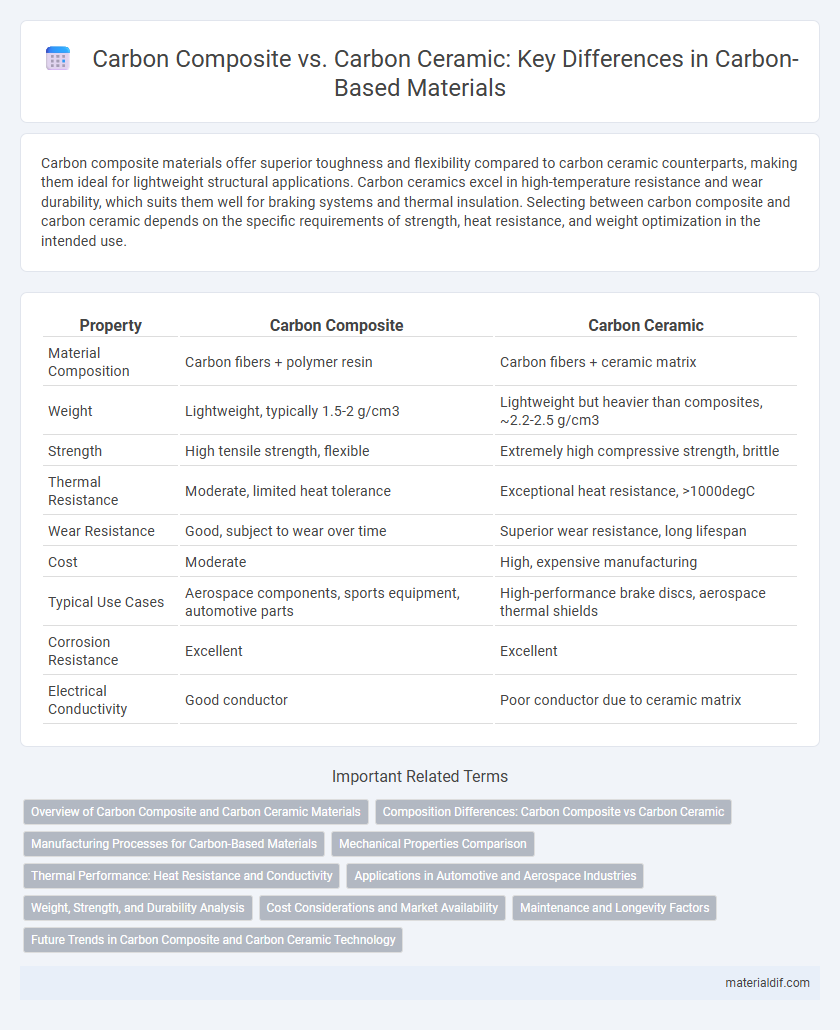

Table of Comparison

| Property | Carbon Composite | Carbon Ceramic |

|---|---|---|

| Material Composition | Carbon fibers + polymer resin | Carbon fibers + ceramic matrix |

| Weight | Lightweight, typically 1.5-2 g/cm3 | Lightweight but heavier than composites, ~2.2-2.5 g/cm3 |

| Strength | High tensile strength, flexible | Extremely high compressive strength, brittle |

| Thermal Resistance | Moderate, limited heat tolerance | Exceptional heat resistance, >1000degC |

| Wear Resistance | Good, subject to wear over time | Superior wear resistance, long lifespan |

| Cost | Moderate | High, expensive manufacturing |

| Typical Use Cases | Aerospace components, sports equipment, automotive parts | High-performance brake discs, aerospace thermal shields |

| Corrosion Resistance | Excellent | Excellent |

| Electrical Conductivity | Good conductor | Poor conductor due to ceramic matrix |

Overview of Carbon Composite and Carbon Ceramic Materials

Carbon composite materials consist of carbon fibers embedded in a polymer matrix, offering high strength-to-weight ratio and excellent fatigue resistance, commonly used in aerospace and automotive applications. Carbon ceramic materials combine carbon fibers with ceramic matrices, providing superior thermal stability, wear resistance, and performance under high-temperature conditions, making them ideal for braking systems and aerospace components. Both materials leverage the unique properties of carbon fibers but differ significantly in matrix composition and thermal management capabilities.

Composition Differences: Carbon Composite vs Carbon Ceramic

Carbon composite consists primarily of carbon fibers embedded in a polymer matrix, resulting in lightweight materials with high tensile strength and flexibility. Carbon ceramic incorporates carbon fibers within a ceramic matrix, typically silicon carbide, enhancing heat resistance and durability under extreme thermal conditions. The key compositional difference lies in the matrix material, which dictates the mechanical and thermal properties suited for applications like aerospace (carbon composite) versus high-performance braking systems (carbon ceramic).

Manufacturing Processes for Carbon-Based Materials

Carbon composites are produced through layering carbon fibers and resin matrices using processes such as lay-up, filament winding, or resin transfer molding, enabling lightweight and high-strength materials commonly used in aerospace and automotive industries. Carbon ceramic materials are manufactured by impregnating carbon fiber preforms with ceramic precursors followed by high-temperature pyrolysis, resulting in components with superior thermal resistance and durability, ideal for braking systems. The manufacturing complexity and processing temperatures of carbon ceramics exceed those of carbon composites, reflecting their enhanced mechanical and thermal properties.

Mechanical Properties Comparison

Carbon composites exhibit high tensile strength and excellent fatigue resistance due to their fiber-reinforced polymer matrix, making them ideal for lightweight structural applications. Carbon ceramics, composed of carbon matrix infiltrated with ceramic phases, offer superior thermal stability and wear resistance but generally have lower tensile strength and higher brittleness compared to carbon composites. Mechanical properties comparison reveals carbon composites excel in strength-to-weight ratio and flexibility, whereas carbon ceramics surpass in hardness, heat tolerance, and fracture toughness under extreme conditions.

Thermal Performance: Heat Resistance and Conductivity

Carbon composites exhibit moderate heat resistance with thermal conductivity ranging from 5 to 10 W/mK, making them suitable for applications requiring lightweight materials with decent heat dissipation. Carbon ceramic materials demonstrate exceptional heat resistance, often exceeding 1000degC, and possess higher thermal conductivity values between 20 to 50 W/mK, enabling superior thermal management in high-temperature environments. These properties make carbon ceramics preferable in aerospace and high-performance braking systems, while carbon composites are favored in structural components where weight savings are critical.

Applications in Automotive and Aerospace Industries

Carbon composites exhibit high strength-to-weight ratios and excellent fatigue resistance, making them ideal for automotive structural components and aerospace airframe parts where weight reduction is critical. Carbon ceramic materials offer superior thermal stability and wear resistance, which are crucial for high-performance automotive brake systems and aerospace turbine engine components. Both materials optimize performance by balancing lightweight design with durability under extreme operational conditions.

Weight, Strength, and Durability Analysis

Carbon composites offer superior weight reduction compared to carbon ceramics, making them ideal for applications requiring lightweight materials. In terms of strength, carbon ceramics provide higher thermal resistance and exceptional hardness, enhancing durability under extreme temperatures and wear conditions. The durability of carbon composites excels in impact resistance and flexibility, while carbon ceramics outperform in abrasion resistance and long-term stability in harsh environments.

Cost Considerations and Market Availability

Carbon composites typically offer a lower cost and greater market availability compared to carbon ceramic materials, making them more accessible for mass production in automotive and aerospace industries. Carbon ceramics, while offering superior heat resistance and durability, come with significantly higher manufacturing costs and limited supply due to complex production processes. The cost difference restricts carbon ceramic use to high-performance, niche applications, whereas carbon composites dominate in broader commercial markets.

Maintenance and Longevity Factors

Carbon composite materials exhibit superior resistance to corrosion and fatigue, resulting in lower maintenance requirements compared to carbon ceramic counterparts. Carbon ceramic components offer exceptional thermal stability and wear resistance, extending longevity under high-temperature conditions but often demand more specialized upkeep. Both materials enhance durability in automotive and aerospace applications, yet carbon composites typically provide a cost-effective balance between maintenance ease and lifespan.

Future Trends in Carbon Composite and Carbon Ceramic Technology

Carbon composite materials are evolving with advancements in nanotechnology, enabling lighter, stronger, and more durable structures critical for aerospace and automotive industries. Carbon ceramic technology is advancing through improved thermal resistance and wear properties, making it ideal for high-performance brake systems and energy-efficient applications. Future trends indicate integration of smart sensors within both materials to enhance performance monitoring and predictive maintenance.

Carbon composite vs Carbon ceramic Infographic

materialdif.com

materialdif.com