Activated carbon offers a highly porous structure with extensive surface area, making it ideal for adsorption and filtration applications. Pyrolytic carbon is characterized by its high purity and crystallinity, providing excellent biocompatibility and mechanical strength, commonly used in medical implants. Differences in their production methods result in distinct physical and chemical properties that suit diverse industrial and biomedical uses.

Table of Comparison

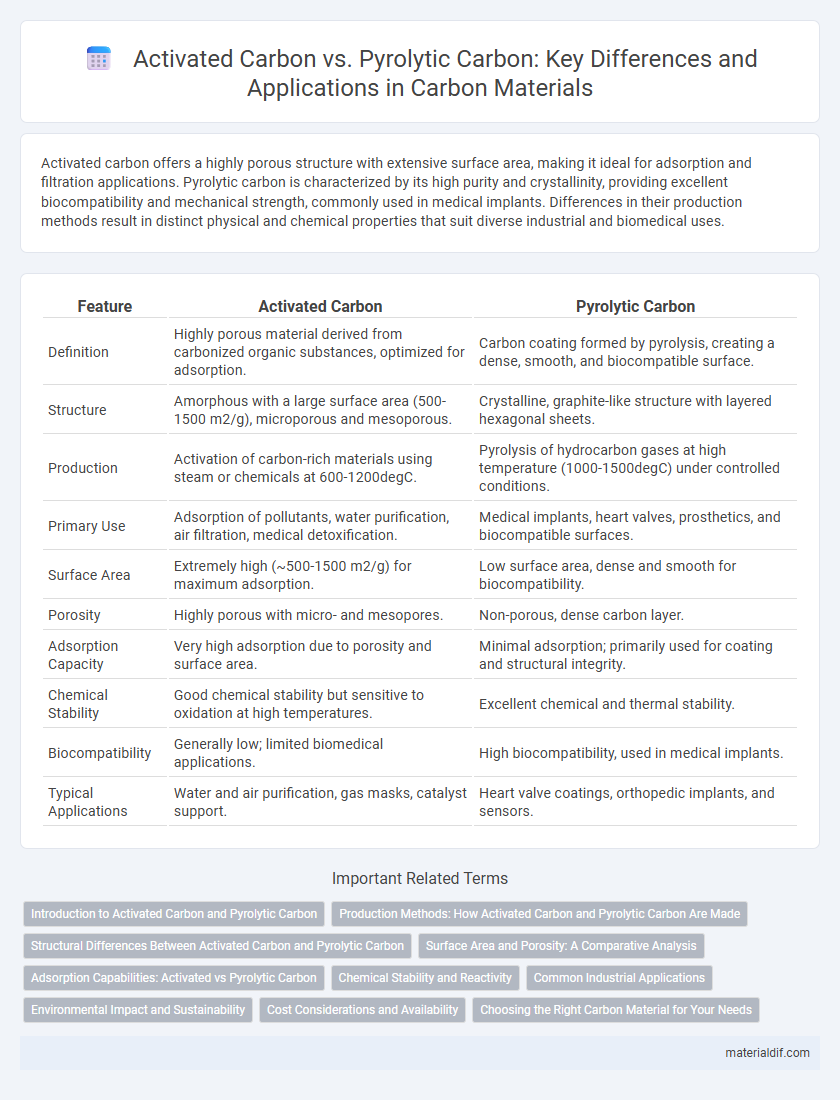

| Feature | Activated Carbon | Pyrolytic Carbon |

|---|---|---|

| Definition | Highly porous material derived from carbonized organic substances, optimized for adsorption. | Carbon coating formed by pyrolysis, creating a dense, smooth, and biocompatible surface. |

| Structure | Amorphous with a large surface area (500-1500 m2/g), microporous and mesoporous. | Crystalline, graphite-like structure with layered hexagonal sheets. |

| Production | Activation of carbon-rich materials using steam or chemicals at 600-1200degC. | Pyrolysis of hydrocarbon gases at high temperature (1000-1500degC) under controlled conditions. |

| Primary Use | Adsorption of pollutants, water purification, air filtration, medical detoxification. | Medical implants, heart valves, prosthetics, and biocompatible surfaces. |

| Surface Area | Extremely high (~500-1500 m2/g) for maximum adsorption. | Low surface area, dense and smooth for biocompatibility. |

| Porosity | Highly porous with micro- and mesopores. | Non-porous, dense carbon layer. |

| Adsorption Capacity | Very high adsorption due to porosity and surface area. | Minimal adsorption; primarily used for coating and structural integrity. |

| Chemical Stability | Good chemical stability but sensitive to oxidation at high temperatures. | Excellent chemical and thermal stability. |

| Biocompatibility | Generally low; limited biomedical applications. | High biocompatibility, used in medical implants. |

| Typical Applications | Water and air purification, gas masks, catalyst support. | Heart valve coatings, orthopedic implants, and sensors. |

Introduction to Activated Carbon and Pyrolytic Carbon

Activated carbon is a highly porous form of carbon known for its exceptional adsorption capacity, widely utilized in water purification, gas filtration, and industrial processes due to its large surface area and ability to trap contaminants. Pyrolytic carbon, produced by the high-temperature decomposition of hydrocarbons in the absence of oxygen, features a highly ordered graphitic structure with excellent thermal stability and mechanical strength, making it ideal for medical implants and high-performance coatings. Both materials derive from carbon but differ significantly in structure, production methods, and applications, with activated carbon emphasizing adsorption and pyrolytic carbon focusing on durability and biocompatibility.

Production Methods: How Activated Carbon and Pyrolytic Carbon Are Made

Activated carbon is produced by carbonizing carbon-rich materials such as coconut shells or coal, followed by a high-temperature activation process using steam or chemicals to create a porous structure that enhances adsorption. Pyrolytic carbon is manufactured through the pyrolysis of hydrocarbon gases in a high-temperature, oxygen-free environment, resulting in a highly ordered, dense carbon coating commonly used in biomedical implants. The stark contrast in production methods leads to activated carbon's extensive surface area for filtration and pyrolytic carbon's structural integrity and biocompatibility.

Structural Differences Between Activated Carbon and Pyrolytic Carbon

Activated carbon features a highly porous structure with an extensive surface area, making it ideal for adsorption applications, whereas pyrolytic carbon exhibits a dense, layered, graphitic structure characterized by hexagonally arranged carbon atoms. The microporosity of activated carbon results from the activation process that develops numerous pores, while pyrolytic carbon forms through chemical vapor deposition or pyrolysis, creating a uniform, crystalline arrangement. These structural differences influence their respective uses, with activated carbon excelling in filtration and purification, and pyrolytic carbon favored in medical implants and electronic components due to its mechanical strength and electrical conductivity.

Surface Area and Porosity: A Comparative Analysis

Activated carbon exhibits significantly higher surface area and porosity compared to pyrolytic carbon, often exceeding 1,000 m2/g due to its highly porous structure. Pyrolytic carbon, characterized by its layered graphite-like morphology, typically presents a lower surface area ranging from 10 to 100 m2/g with limited microporosity. This contrast makes activated carbon more effective for adsorption applications, while pyrolytic carbon excels in structural and conductive roles.

Adsorption Capabilities: Activated vs Pyrolytic Carbon

Activated carbon exhibits superior adsorption capabilities compared to pyrolytic carbon due to its highly porous structure and extensive surface area, enabling efficient trapping of contaminants and organic molecules. Pyrolytic carbon, while chemically stable and smooth, presents a denser morphology with lower surface area, resulting in reduced adsorption capacity. Industrial applications prioritize activated carbon for water purification and gas treatment, leveraging its enhanced adsorption efficiency over pyrolytic carbon.

Chemical Stability and Reactivity

Activated carbon exhibits high chemical stability due to its porous structure and predominantly aromatic carbon framework, making it resistant to many chemical reagents and suitable for adsorption applications. Pyrolytic carbon, synthesized through thermal decomposition of hydrocarbons, offers enhanced chemical inertness and exceptional resistance to oxidation and corrosion, especially at elevated temperatures. The lower reactivity of pyrolytic carbon compared to activated carbon makes it preferred for biomedical implants and high-temperature environments.

Common Industrial Applications

Activated carbon excels in industrial applications such as water purification, air filtration, and chemical purification due to its highly porous structure and strong adsorption capacity. Pyrolytic carbon, characterized by its high density and chemical stability, is primarily used in medical implants and high-temperature crucibles. Both forms of carbon serve critical roles in industries requiring absorption, filtration, and thermal resistance, with activated carbon favored for environmental remediation and pyrolytic carbon for durability in extreme conditions.

Environmental Impact and Sustainability

Activated carbon is widely used for environmental remediation due to its high adsorption capacity, efficiently removing pollutants from air and water, which supports sustainability efforts. Pyrolytic carbon, produced through controlled thermal decomposition, offers durability and inertness beneficial in medical applications but has a less significant role in environmental cleanup. Evaluating life cycle emissions shows activated carbon generally presents a lower environmental footprint, making it a preferred choice for eco-friendly pollution control technologies.

Cost Considerations and Availability

Activated carbon is widely available and generally more cost-effective due to mass production from abundant raw materials like coconut shells and coal. Pyrolytic carbon, produced through specialized chemical vapor deposition, incurs higher manufacturing costs and is less readily available, limiting its use to niche applications. The price difference reflects the scalability and supply chain efficiency favoring activated carbon over pyrolytic carbon in most commercial markets.

Choosing the Right Carbon Material for Your Needs

Activated carbon features a highly porous structure ideal for adsorption applications like water purification and air filtration, offering exceptional surface area for contaminant removal. Pyrolytic carbon, produced through controlled thermal decomposition, provides superior mechanical strength and biocompatibility, making it suitable for medical implants and high-temperature industrial uses. Selecting the right carbon material depends on specific requirements such as adsorption capacity, mechanical durability, and application environment.

Activated carbon vs Pyrolytic carbon Infographic

materialdif.com

materialdif.com