Carbon-reinforced polymer offers superior strength-to-weight ratio and corrosion resistance, making it ideal for lightweight, high-performance applications. Carbon/aluminum hybrids combine the stiffness and thermal conductivity of aluminum with the durability and flexibility of carbon fiber, resulting in enhanced structural integrity and impact resistance. This hybrid approach optimizes material properties for automotive and aerospace industries, balancing performance with cost-effectiveness.

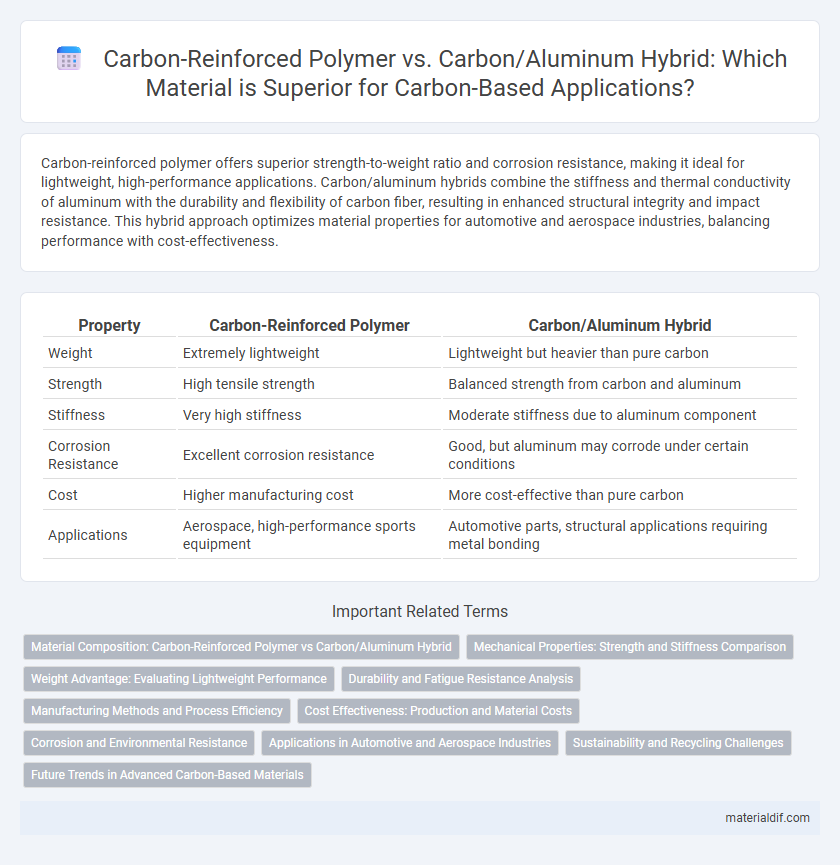

Table of Comparison

| Property | Carbon-Reinforced Polymer | Carbon/Aluminum Hybrid |

|---|---|---|

| Weight | Extremely lightweight | Lightweight but heavier than pure carbon |

| Strength | High tensile strength | Balanced strength from carbon and aluminum |

| Stiffness | Very high stiffness | Moderate stiffness due to aluminum component |

| Corrosion Resistance | Excellent corrosion resistance | Good, but aluminum may corrode under certain conditions |

| Cost | Higher manufacturing cost | More cost-effective than pure carbon |

| Applications | Aerospace, high-performance sports equipment | Automotive parts, structural applications requiring metal bonding |

Material Composition: Carbon-Reinforced Polymer vs Carbon/Aluminum Hybrid

Carbon-reinforced polymers consist primarily of carbon fibers embedded in a polymer matrix, offering high strength-to-weight ratios and exceptional fatigue resistance. Carbon/aluminum hybrids combine carbon fibers with aluminum layers, enhancing impact resistance and thermal conductivity while maintaining reduced weight. The synergy between carbon and aluminum in hybrids results in improved structural integrity and corrosion resistance compared to pure carbon-reinforced polymers.

Mechanical Properties: Strength and Stiffness Comparison

Carbon-reinforced polymers (CFRPs) exhibit superior strength-to-weight ratios and exceptional stiffness due to their continuous carbon fiber matrix, making them ideal for high-performance structural applications. In contrast, carbon/aluminum hybrids combine the lightweight nature and corrosion resistance of aluminum with carbon fiber's high tensile strength, resulting in enhanced impact resistance and improved load distribution. The hybrid materials often demonstrate better fatigue performance and damage tolerance, while pure CFRPs provide higher stiffness, crucial for aerospace and automotive components requiring minimal deformation under stress.

Weight Advantage: Evaluating Lightweight Performance

Carbon-reinforced polymers offer significant weight reduction with densities around 1.5-1.6 g/cm3, outperforming traditional aluminum at approximately 2.7 g/cm3, which directly translates into enhanced fuel efficiency and structural performance. Carbon/aluminum hybrids balance strength and weight by integrating lightweight aluminum alloys with carbon composites, achieving optimized stiffness-to-weight ratios and improved impact resistance for automotive and aerospace applications. Evaluating lightweight performance involves assessing specific strength and stiffness metrics, where carbon-reinforced polymers excel in minimizing mass while hybrid configurations provide tailored mechanical properties for multifunctional designs.

Durability and Fatigue Resistance Analysis

Carbon-reinforced polymer (CRP) demonstrates superior fatigue resistance due to its homogenous fiber-matrix structure, which effectively distributes stress and prevents crack propagation. In contrast, carbon/aluminum hybrids exhibit increased durability through the metal's toughness but face challenges with delamination and galvanic corrosion at the fiber-metal interface. Analysis reveals that while CRP offers excellent cyclic loading performance, the hybrid's mechanical resilience benefits from aluminum's ductility, making the choice application-dependent.

Manufacturing Methods and Process Efficiency

Carbon-reinforced polymer (CFRP) manufacturing primarily involves processes like resin transfer molding (RTM) and autoclave curing, which offer high precision but often require longer cycle times and substantial energy input. In contrast, carbon/aluminum hybrid structures benefit from combining automated aluminum forming techniques such as extrusion or stamping with bonding or co-curing methods for carbon components, resulting in enhanced process efficiency and faster production cycles. The hybrid approach reduces total manufacturing time and energy consumption by optimizing each material's forming process, thereby improving overall production throughput and cost-effectiveness.

Cost Effectiveness: Production and Material Costs

Carbon-reinforced polymer offers lower production costs due to simpler manufacturing processes and reduced material expenses compared to carbon/aluminum hybrids. The hybrid materials involve more complex fabrication techniques and higher raw material costs from aluminum alloys, increasing overall production expenses. Cost-effectiveness favors carbon-reinforced polymers in applications where budget constraints are critical without sacrificing performance.

Corrosion and Environmental Resistance

Carbon-reinforced polymers exhibit superior corrosion resistance due to their inert polymer matrix, preventing degradation in harsh environmental conditions. In contrast, carbon/aluminum hybrids may suffer from galvanic corrosion at the interface between carbon fibers and aluminum, necessitating protective coatings or treatments. Environmental resistance is higher in carbon-reinforced polymers as they resist moisture, chemicals, and UV exposure better than aluminum-based hybrids, which can oxidize and weaken over time.

Applications in Automotive and Aerospace Industries

Carbon-reinforced polymers (CRPs) offer lightweight strength and corrosion resistance ideal for automotive body panels and aerospace structural components, enhancing fuel efficiency and performance. Carbon/aluminum hybrids combine aluminum's ductility with carbon fiber's tensile strength, making them suitable for complex automotive frames and aerospace fuselage sections requiring durability and impact resistance. These materials accelerate innovation in vehicle and aircraft design by reducing weight while maintaining high mechanical integrity.

Sustainability and Recycling Challenges

Carbon-reinforced polymers offer high strength-to-weight ratios but pose significant sustainability challenges due to their non-biodegradable nature and difficulty in recycling, often requiring energy-intensive processes. Carbon/aluminum hybrids provide improved recyclability as aluminum components can be more easily separated and recycled, yet the integration of carbon fibers complicates material recovery and reduces overall recyclability rates. Both materials demand innovative recycling technologies and circular economy approaches to minimize environmental impact and promote sustainable lifecycle management.

Future Trends in Advanced Carbon-Based Materials

Future trends in advanced carbon-based materials emphasize enhanced mechanical strength and weight reduction, with carbon-reinforced polymers offering superior flexibility and corrosion resistance. Carbon/aluminum hybrids provide a balance of structural integrity and cost efficiency, promoting broader applications in automotive and aerospace industries. Innovations in nanotechnology and bio-based polymers are expected to further optimize material performance and sustainability.

Carbon-reinforced polymer vs Carbon/aluminum hybrid Infographic

materialdif.com

materialdif.com