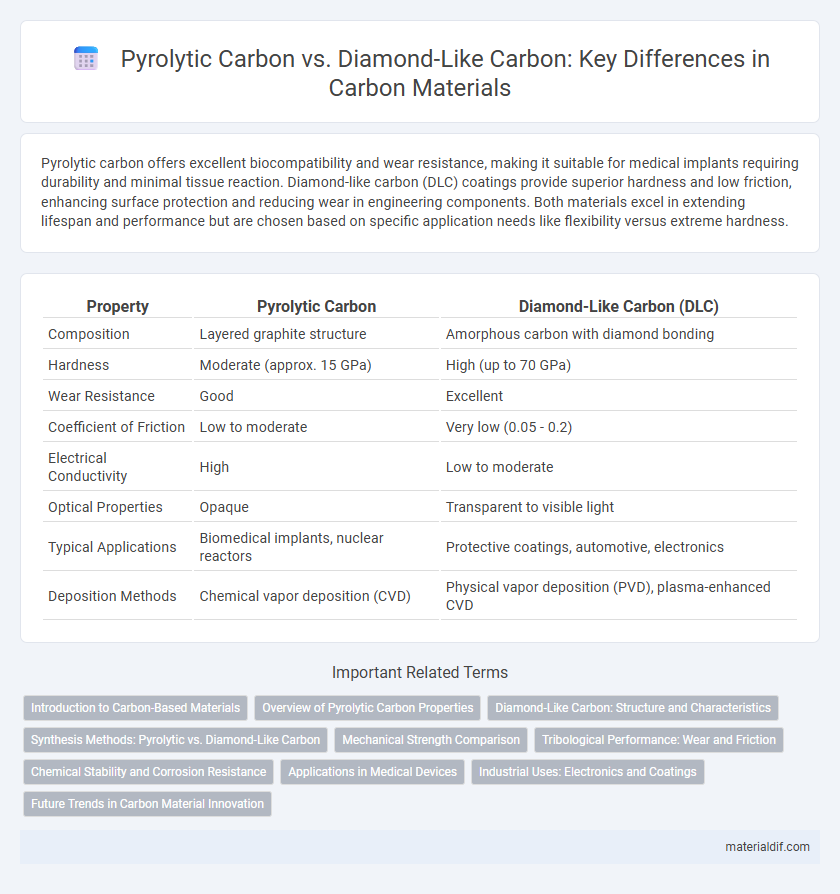

Pyrolytic carbon offers excellent biocompatibility and wear resistance, making it suitable for medical implants requiring durability and minimal tissue reaction. Diamond-like carbon (DLC) coatings provide superior hardness and low friction, enhancing surface protection and reducing wear in engineering components. Both materials excel in extending lifespan and performance but are chosen based on specific application needs like flexibility versus extreme hardness.

Table of Comparison

| Property | Pyrolytic Carbon | Diamond-Like Carbon (DLC) |

|---|---|---|

| Composition | Layered graphite structure | Amorphous carbon with diamond bonding |

| Hardness | Moderate (approx. 15 GPa) | High (up to 70 GPa) |

| Wear Resistance | Good | Excellent |

| Coefficient of Friction | Low to moderate | Very low (0.05 - 0.2) |

| Electrical Conductivity | High | Low to moderate |

| Optical Properties | Opaque | Transparent to visible light |

| Typical Applications | Biomedical implants, nuclear reactors | Protective coatings, automotive, electronics |

| Deposition Methods | Chemical vapor deposition (CVD) | Physical vapor deposition (PVD), plasma-enhanced CVD |

Introduction to Carbon-Based Materials

Pyrolytic carbon and diamond-like carbon (DLC) are two prominent carbon-based materials distinguished by their unique structural and mechanical properties. Pyrolytic carbon features a layered, graphitic structure with high thermal stability and biocompatibility, making it suitable for medical implants and high-temperature applications. Diamond-like carbon exhibits a predominantly amorphous structure with a high fraction of sp3 bonds, offering exceptional hardness, low friction, and chemical inertness, ideal for protective coatings and wear-resistant surfaces.

Overview of Pyrolytic Carbon Properties

Pyrolytic carbon exhibits a highly anisotropic structure with excellent thermal stability, chemical inertness, and biocompatibility, making it ideal for medical implants and high-temperature applications. Its layered, graphitic microstructure provides superior wear resistance and low friction coefficients compared to diamond-like carbon. Unlike diamond-like carbon, pyrolytic carbon possesses moderate electrical conductivity, enhancing its utility in electronic components and biomedical devices.

Diamond-Like Carbon: Structure and Characteristics

Diamond-like carbon (DLC) features an amorphous structure combining sp2 and sp3 hybridized carbon atoms, resulting in exceptional hardness and chemical inertness. Unlike pyrolytic carbon, DLC exhibits low friction and high wear resistance, making it ideal for protective coatings in medical and industrial applications. Its tunable mechanical and optical properties stem from variable hydrogen content and deposition methods, enhancing versatility across industries.

Synthesis Methods: Pyrolytic vs. Diamond-Like Carbon

Pyrolytic carbon is synthesized through the thermal decomposition of hydrocarbon gases at high temperatures, typically above 1000degC, resulting in a graphitic structure with high thermal stability and anisotropic properties. Diamond-like carbon (DLC) is produced using physical vapor deposition (PVD) or chemical vapor deposition (CVD) techniques, often involving plasma-enhanced methods that create amorphous carbon films with sp3 bonding characteristics similar to diamond. These distinct synthesis approaches directly influence the microstructure, mechanical hardness, and tribological performance of pyrolytic carbon and diamond-like carbon coatings.

Mechanical Strength Comparison

Pyrolytic carbon exhibits notable mechanical strength with high wear resistance and excellent load-bearing capacity due to its anisotropic layered structure, making it ideal for biomedical implants and mechanical components. Diamond-like carbon (DLC) films, characterized by their amorphous carbon matrix with sp3 bonding, offer superior hardness and elastic modulus, resulting in outstanding scratch resistance and low friction coefficients. Comparatively, DLC provides higher hardness and stiffness, while pyrolytic carbon delivers enhanced toughness and fatigue resistance, emphasizing distinct application advantages based on mechanical performance requirements.

Tribological Performance: Wear and Friction

Pyrolytic carbon exhibits exceptional wear resistance and low friction coefficients due to its graphitic layered structure, making it ideal for high-friction applications such as joint implants. Diamond-like carbon (DLC) coatings provide superior hardness and low wear rates with ultra-low friction properties, attributed to their amorphous carbon network containing sp3 bonds. Comparative studies demonstrate DLC outperforms pyrolytic carbon in minimizing adhesive wear and maintaining stable friction under varying load conditions.

Chemical Stability and Corrosion Resistance

Pyrolytic carbon exhibits exceptional chemical stability due to its graphitic microstructure, making it highly resistant to oxidation and chemical corrosion in harsh environments. Diamond-like carbon (DLC) films possess superior corrosion resistance thanks to their amorphous carbon matrix with high sp3 bonding, which provides excellent inertness and barrier properties against aggressive chemicals. Both materials offer remarkable durability, but DLC generally outperforms pyrolytic carbon in resisting corrosive agents due to its dense, defect-free surface.

Applications in Medical Devices

Pyrolytic carbon exhibits exceptional biocompatibility and wear resistance, making it ideal for heart valve prostheses and orthopedic implants. Diamond-like carbon (DLC) coatings offer superior hardness and low friction properties, enhancing the durability of stents, catheters, and joint replacements. Both materials improve device longevity and patient outcomes by reducing wear and minimizing biological reactions in medical applications.

Industrial Uses: Electronics and Coatings

Pyrolytic carbon and diamond-like carbon (DLC) serve distinct roles in industrial applications, particularly in electronics and coatings. Pyrolytic carbon, known for its high thermal stability and electrical conductivity, is commonly used in semiconductor devices and as protective coatings for electronic components. Diamond-like carbon offers superior hardness, low friction, and excellent chemical resistance, making it ideal for wear-resistant coatings on hard disks, cutting tools, and medical implants.

Future Trends in Carbon Material Innovation

Pyrolytic carbon and diamond-like carbon (DLC) represent two advanced forms of carbon with distinct properties and applications, driving innovation in various industries. Emerging trends focus on enhancing the thermal stability, electrical conductivity, and wear resistance of these materials using nanostructuring and doping techniques to meet specific industrial demands. Future innovations aim to integrate these carbon materials into flexible electronics, biocompatible devices, and sustainable energy systems, leveraging their unique mechanical and chemical properties for improved performance and durability.

Pyrolytic carbon vs Diamond-like carbon Infographic

materialdif.com

materialdif.com