Isotropic carbon exhibits uniform properties in all directions, making it ideal for applications requiring consistent strength and thermal conductivity. Anisotropic carbon, on the other hand, has directional properties that vary based on its orientation, offering enhanced performance in specific directions. Understanding the differences between isotropic and anisotropic carbon is crucial for optimizing materials in aerospace, electronics, and industrial manufacturing.

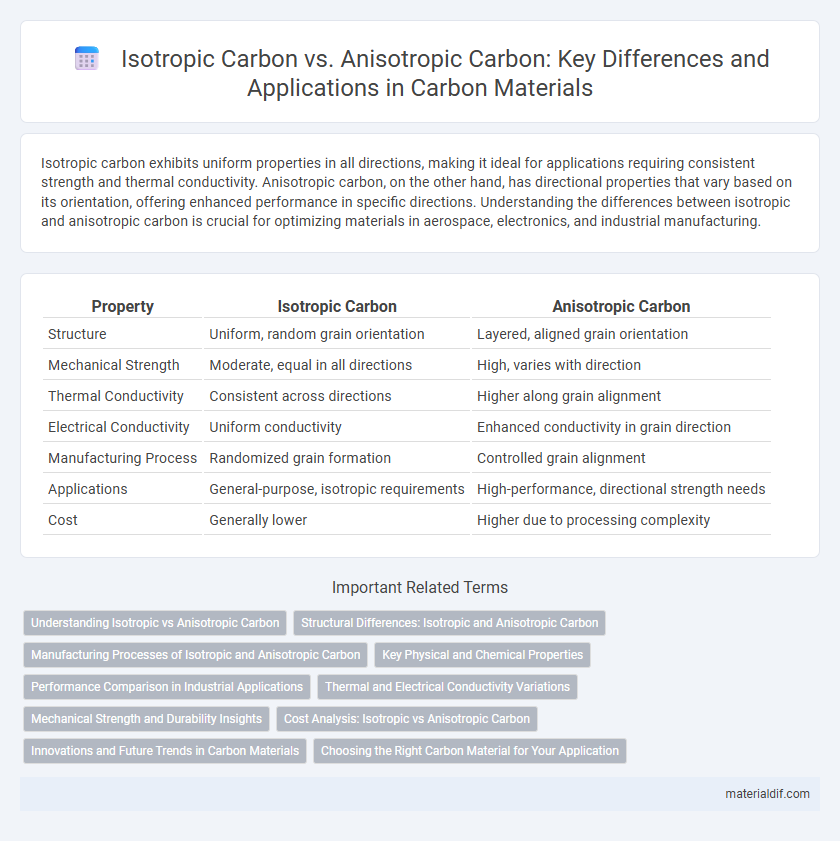

Table of Comparison

| Property | Isotropic Carbon | Anisotropic Carbon |

|---|---|---|

| Structure | Uniform, random grain orientation | Layered, aligned grain orientation |

| Mechanical Strength | Moderate, equal in all directions | High, varies with direction |

| Thermal Conductivity | Consistent across directions | Higher along grain alignment |

| Electrical Conductivity | Uniform conductivity | Enhanced conductivity in grain direction |

| Manufacturing Process | Randomized grain formation | Controlled grain alignment |

| Applications | General-purpose, isotropic requirements | High-performance, directional strength needs |

| Cost | Generally lower | Higher due to processing complexity |

Understanding Isotropic vs Anisotropic Carbon

Isotropic carbon features uniform properties in all directions, resulting from randomly oriented carbon grains, making it ideal for applications requiring consistent strength and thermal stability. Anisotropic carbon, conversely, exhibits directional properties due to aligned carbon structures, enhancing performance in specific orientations such as electrical conductivity or mechanical strength. Understanding these differences is crucial for selecting the appropriate carbon type in industries like aerospace, automotive, and electronics.

Structural Differences: Isotropic and Anisotropic Carbon

Isotropic carbon features a uniform microstructure with randomly oriented carbon crystallites, resulting in consistent mechanical and thermal properties in all directions. Anisotropic carbon exhibits a highly ordered, aligned structure where carbon layers are oriented predominantly in one direction, leading to directional variations in strength, thermal conductivity, and electrical properties. These structural differences profoundly affect performance in applications such as electrodes, refractories, and composite materials.

Manufacturing Processes of Isotropic and Anisotropic Carbon

Isotropic carbon is manufactured through a controlled graphitization process of isotropic pitches or resins, resulting in uniform physical properties in all directions. Anisotropic carbon is produced by thermal decomposition of mesophase pitch, creating aligned microstructures that exhibit directional properties. Manufacturing anisotropic carbon requires precise temperature control and mechanical treatment to achieve the desired orientation in the carbon matrix.

Key Physical and Chemical Properties

Isotropic carbon exhibits uniform physical and chemical properties in all directions due to its randomly oriented microstructure, resulting in consistent thermal conductivity, electrical resistivity, and mechanical strength. Anisotropic carbon displays direction-dependent characteristics, with higher thermal conductivity and strength along the aligned grain structures, influenced by its ordered crystalline arrangement. The choice between isotropic and anisotropic carbon impacts performance in applications requiring specific thermal management, electrical conductivity, or mechanical durability.

Performance Comparison in Industrial Applications

Isotropic carbon exhibits uniform properties in all directions, enhancing its reliability in applications requiring consistent mechanical strength and thermal conductivity, such as electrodes in electric arc furnaces. Anisotropic carbon, with direction-dependent properties, offers superior performance in high-stress environments like aerospace components due to its enhanced tensile strength and resistance to thermal shock along specific orientations. Industrial applications prioritize isotropic carbon for stability and uniformity, while anisotropic carbon is favored where directional strength and tailored thermal expansion improve efficiency and durability.

Thermal and Electrical Conductivity Variations

Isotropic carbon exhibits uniform thermal and electrical conductivity in all directions due to its random microstructure, making it suitable for applications requiring consistent performance under thermal stress. In contrast, anisotropic carbon has directional properties where thermal and electrical conductivity vary significantly along different axes, attributed to its aligned carbon layers or grains. This directional conductivity in anisotropic carbon enhances heat dissipation and electrical flow in specific orientations, critical for high-performance electronic devices and thermal management systems.

Mechanical Strength and Durability Insights

Isotropic carbon exhibits uniform mechanical strength and durability due to its randomly oriented microstructure, making it resistant to stress from multiple directions. Anisotropic carbon, characterized by aligned carbon planes, offers superior strength and stiffness along specific orientations but may be prone to weaknesses when stress is applied perpendicularly. Understanding these differences is critical for applications requiring tailored mechanical performance and long-lasting material resilience.

Cost Analysis: Isotropic vs Anisotropic Carbon

Isotropic carbon generally incurs higher production costs than anisotropic carbon due to its uniform molecular structure and energy-intensive manufacturing processes. Anisotropic carbon offers cost advantages by leveraging directional properties that reduce raw material usage and optimize thermal conductivity. Industries often prefer anisotropic carbon for cost efficiency in applications where directional performance meets operational requirements.

Innovations and Future Trends in Carbon Materials

Innovations in isotropic carbon focus on enhancing uniform properties through advanced manufacturing techniques such as chemical vapor deposition and high-pressure processing, which improve performance in aerospace and electronics. Anisotropic carbon materials, including carbon fiber composites and graphene derivatives, benefit from directional property optimization, enabling breakthroughs in lightweight structural components and flexible electronics. Future trends emphasize integrating nanotechnology and bio-inspired designs to develop multifunctional carbon materials with tunable isotropic and anisotropic properties for energy storage and environmental applications.

Choosing the Right Carbon Material for Your Application

Isotropic carbon exhibits uniform properties in all directions, making it ideal for applications requiring consistent performance under multidirectional stresses, such as electrical contacts and heating elements. Anisotropic carbon offers directional strength and thermal conductivity, suited for structural components and aerospace applications where tailored mechanical properties are critical. Selecting the right carbon material depends on the specific application's mechanical, thermal, and electrical requirements, ensuring optimum durability and efficiency.

Isotropic Carbon vs Anisotropic Carbon Infographic

materialdif.com

materialdif.com