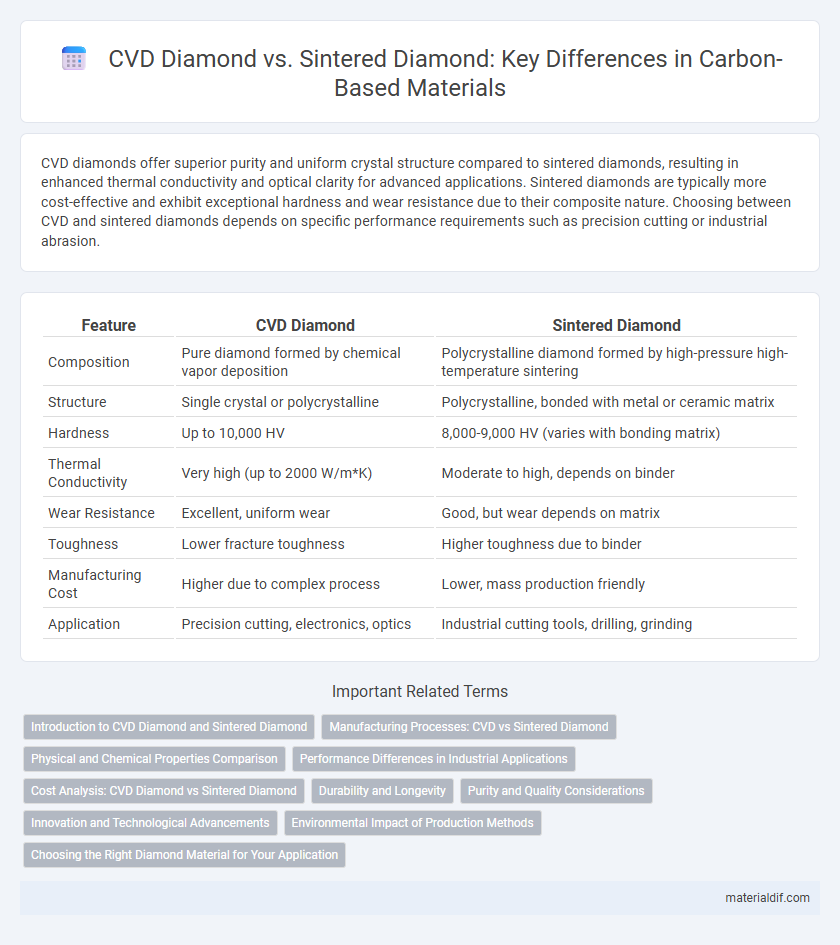

CVD diamonds offer superior purity and uniform crystal structure compared to sintered diamonds, resulting in enhanced thermal conductivity and optical clarity for advanced applications. Sintered diamonds are typically more cost-effective and exhibit exceptional hardness and wear resistance due to their composite nature. Choosing between CVD and sintered diamonds depends on specific performance requirements such as precision cutting or industrial abrasion.

Table of Comparison

| Feature | CVD Diamond | Sintered Diamond |

|---|---|---|

| Composition | Pure diamond formed by chemical vapor deposition | Polycrystalline diamond formed by high-pressure high-temperature sintering |

| Structure | Single crystal or polycrystalline | Polycrystalline, bonded with metal or ceramic matrix |

| Hardness | Up to 10,000 HV | 8,000-9,000 HV (varies with bonding matrix) |

| Thermal Conductivity | Very high (up to 2000 W/m*K) | Moderate to high, depends on binder |

| Wear Resistance | Excellent, uniform wear | Good, but wear depends on matrix |

| Toughness | Lower fracture toughness | Higher toughness due to binder |

| Manufacturing Cost | Higher due to complex process | Lower, mass production friendly |

| Application | Precision cutting, electronics, optics | Industrial cutting tools, drilling, grinding |

Introduction to CVD Diamond and Sintered Diamond

CVD diamond is a synthetic diamond produced through chemical vapor deposition, offering high purity and uniformity ideal for industrial cutting tools and optical applications. Sintered diamond combines diamond particles bonded under high temperature and pressure, delivering exceptional hardness and wear resistance for abrasive and grinding tools. Both materials leverage carbon's exceptional properties but differ significantly in structure, manufacturing processes, and typical use cases.

Manufacturing Processes: CVD vs Sintered Diamond

Chemical Vapor Deposition (CVD) diamond manufacturing involves depositing carbon atoms onto a substrate in a controlled plasma environment, resulting in high-purity, single-crystal or polycrystalline diamond films with excellent uniformity. Sintered diamond production relies on high-pressure, high-temperature (HPHT) processes that fuse diamond particles with a metal binder, creating a composite material known for its toughness and wear resistance. The distinct manufacturing techniques lead to differences in diamond quality, composition, and application suitability, with CVD diamonds excelling in electronic and optical uses, while sintered diamonds dominate cutting and grinding tool markets.

Physical and Chemical Properties Comparison

CVD diamonds exhibit exceptional purity and homogeneity, resulting in superior thermal conductivity and greater chemical stability compared to sintered diamonds, which often contain binder phases that compromise hardness and thermal performance. The physical structure of CVD diamonds is characterized by a single-crystal lattice, providing higher wear resistance and strength, whereas sintered diamonds, composed of polycrystalline aggregates bonded with metal or ceramic binders, display enhanced toughness but lower hardness. Chemically, CVD diamonds resist oxidation and chemical attacks at elevated temperatures better than sintered diamonds due to minimal impurities and absence of binder materials.

Performance Differences in Industrial Applications

CVD diamond exhibits superior thermal conductivity and chemical stability compared to sintered diamond, making it ideal for high-precision cutting and wear-resistant applications in industries such as electronics and aerospace. Sintered diamond, while offering higher toughness and shock resistance, is preferred for heavy-duty drilling and grinding where mechanical strength is critical. Performance differences hinge on the operational environment, with CVD diamonds excelling in precision and sintered diamonds in durability under extreme mechanical stress.

Cost Analysis: CVD Diamond vs Sintered Diamond

CVD diamond typically incurs higher initial costs due to complex manufacturing processes involving chemical vapor deposition, but offers superior purity and performance, justifying the expense in high-precision applications. Sintered diamond presents a cost-effective alternative with lower production costs through powder metallurgy, making it suitable for large-scale industrial uses where extreme performance is less critical. Evaluating the total cost of ownership, including durability and application-specific efficiency, is essential for an accurate cost analysis between CVD and sintered diamond materials.

Durability and Longevity

CVD diamond exhibits superior durability and longevity compared to sintered diamond due to its single-crystal structure, which offers enhanced resistance to wear and fracture. Sintered diamonds, composed of polycrystalline particles bonded under high pressure, often display lower toughness and are more prone to microcracking under stress. The exceptional hardness and chemical stability of CVD diamonds ensure longer service life in cutting and industrial applications.

Purity and Quality Considerations

CVD diamond exhibits superior purity due to its controlled chemical vapor deposition process, resulting in fewer impurities and lattice defects compared to sintered diamond, which is often composed of polycrystalline aggregates with potential contamination from binders. The quality of CVD diamonds is characterized by high optical clarity and consistent mechanical properties, making them ideal for precision applications, whereas sintered diamonds, while tougher due to their composite nature, generally show variability in grain size and distribution affecting performance consistency. In high-purity and high-quality demanding industries such as electronics and optics, CVD diamonds are preferred over sintered diamonds due to their uniform crystal structure and minimal inclusions.

Innovation and Technological Advancements

CVD diamond technology offers superior purity and customizable properties through advanced chemical vapor deposition processes, enabling innovative applications in electronics and optics. Sintered diamond combines synthetic diamond particles with metallic binders, providing enhanced toughness and wear resistance critical for cutting-edge industrial tools. Technological advancements in CVD focus on atomic-level control and defect minimization, while sintered diamond innovations optimize grain size and binder composition for improved mechanical performance.

Environmental Impact of Production Methods

CVD diamond production utilizes low-pressure chemical vapor deposition, consuming less energy and producing fewer emissions compared to the high-temperature, high-pressure processes of sintered diamond manufacturing. The sintered diamond method relies heavily on metal catalysts and generates significant industrial waste, contributing to environmental pollution. Advances in CVD technology enable cleaner synthesis with reduced carbon footprint and minimal hazardous material use.

Choosing the Right Diamond Material for Your Application

CVD diamond offers superior purity and uniformity, making it ideal for high-precision optical and electronic applications requiring excellent thermal conductivity and chemical stability. Sintered diamond, composed of aggregated diamond grains bound by a metal matrix, excels in cutting and drilling tools due to its enhanced toughness and wear resistance. Selecting the right diamond material depends on application demands such as hardness, thermal properties, and cost efficiency, with CVD diamonds favored for precision and sintered diamonds preferred for abrasive durability.

CVD diamond vs Sintered diamond Infographic

materialdif.com

materialdif.com