Epoxy carbon composites offer superior stiffness and thermal resistance due to their thermosetting matrix, making them ideal for high-performance aerospace and automotive parts. Thermoplastic carbon composites, while generally less stiff, provide enhanced impact resistance and recyclability, enabling faster manufacturing cycles and easier repair. The choice between epoxy and thermoplastic composites depends on specific application needs, balancing mechanical properties with production efficiency.

Table of Comparison

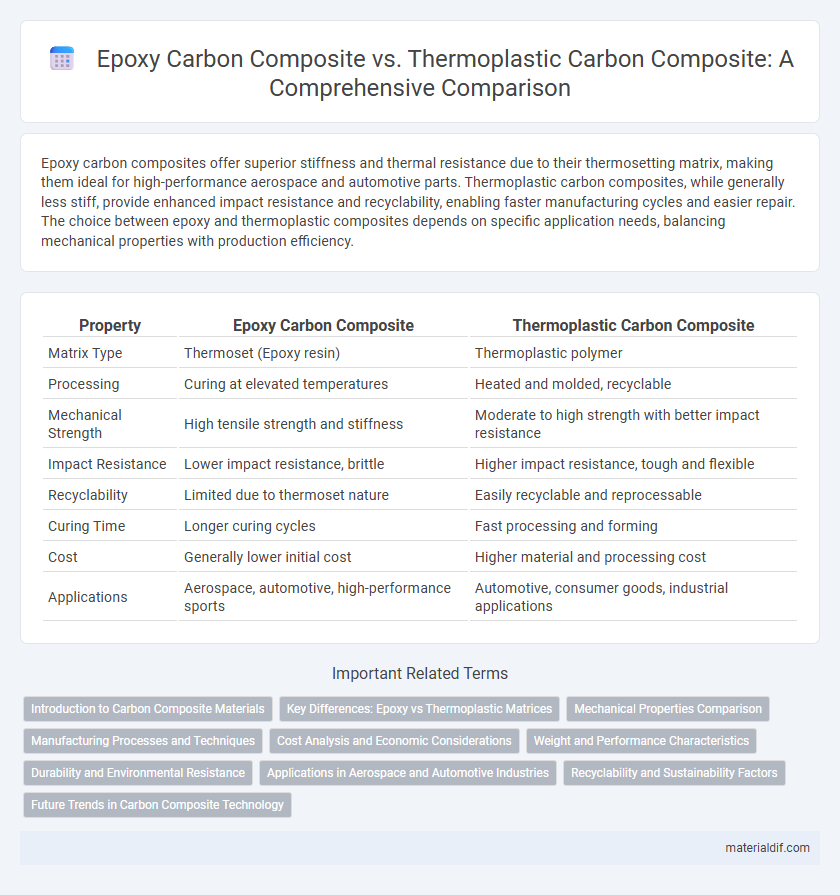

| Property | Epoxy Carbon Composite | Thermoplastic Carbon Composite |

|---|---|---|

| Matrix Type | Thermoset (Epoxy resin) | Thermoplastic polymer |

| Processing | Curing at elevated temperatures | Heated and molded, recyclable |

| Mechanical Strength | High tensile strength and stiffness | Moderate to high strength with better impact resistance |

| Impact Resistance | Lower impact resistance, brittle | Higher impact resistance, tough and flexible |

| Recyclability | Limited due to thermoset nature | Easily recyclable and reprocessable |

| Curing Time | Longer curing cycles | Fast processing and forming |

| Cost | Generally lower initial cost | Higher material and processing cost |

| Applications | Aerospace, automotive, high-performance sports | Automotive, consumer goods, industrial applications |

Introduction to Carbon Composite Materials

Epoxy carbon composites exhibit superior mechanical strength and thermal stability due to the thermosetting nature of epoxy resin, making them ideal for high-performance aerospace and automotive applications. Thermoplastic carbon composites offer enhanced toughness, faster processing times, and recyclability, which reduce manufacturing costs and improve sustainability in industries such as consumer electronics and sports equipment. The selection between epoxy and thermoplastic carbon composites depends on application-specific requirements including impact resistance, thermal endurance, and production efficiency.

Key Differences: Epoxy vs Thermoplastic Matrices

Epoxy carbon composites feature a thermosetting matrix that provides superior mechanical strength, high thermal stability, and excellent chemical resistance, making them ideal for aerospace and automotive applications. Thermoplastic carbon composites utilize a melt-processable matrix offering enhanced impact resistance, faster manufacturing cycles, and easier recycling capabilities compared to epoxy. The key differences lie in cure mechanisms, mechanical performance, and recyclability, with epoxy matrices being rigid and durable, while thermoplastics offer flexibility and reusability.

Mechanical Properties Comparison

Epoxy carbon composites exhibit superior mechanical properties such as higher tensile strength, stiffness, and fatigue resistance compared to thermoplastic carbon composites, making them ideal for high-performance applications like aerospace and automotive industries. Thermoplastic carbon composites offer enhanced impact resistance and recyclability but generally have lower interlaminar shear strength and thermal stability. The choice between epoxy and thermoplastic carbon composites depends on the balance between mechanical performance requirements and lifecycle considerations.

Manufacturing Processes and Techniques

Epoxy carbon composites are primarily manufactured using hand lay-up, vacuum bagging, and autoclave curing, which allows for precise fiber alignment and high resin infusion, resulting in superior mechanical properties. Thermoplastic carbon composites utilize processes such as automated tape placement (ATP) and thermoforming, offering faster cycle times and enhanced recyclability due to the thermoplastic matrix's ability to be reheated and reshaped. The choice between epoxy and thermoplastic carbon composites hinges on the trade-off between the high strength and stiffness achievable through thermosetting epoxy curing and the manufacturing efficiency and impact resistance provided by thermoplastic techniques.

Cost Analysis and Economic Considerations

Epoxy carbon composites generally offer superior mechanical properties but come with higher production costs due to energy-intensive curing processes and longer cycle times. Thermoplastic carbon composites provide cost advantages through faster manufacturing, recyclability, and reduced labor expenses, making them economically favorable for high-volume applications. Economic considerations must balance initial material costs against lifecycle savings and potential for reuse or repair when selecting between these composite types.

Weight and Performance Characteristics

Epoxy carbon composites offer superior stiffness and strength-to-weight ratios compared to thermoplastic carbon composites, making them ideal for high-performance applications that demand rigidity and lightweight structures. Thermoplastic carbon composites provide enhanced impact resistance and greater toughness, enabling better durability and recyclability without significantly compromising weight. Weight savings typically favor epoxy composites, but thermoplastic composites excel in applications requiring repeated stress and rapid manufacturing cycles.

Durability and Environmental Resistance

Epoxy carbon composites exhibit superior durability due to their high cross-link density, providing excellent mechanical strength and resistance to fatigue and impact. Thermoplastic carbon composites offer enhanced environmental resistance, including improved resistance to moisture, chemicals, and UV radiation, which contributes to longer lifespan in harsh conditions. The choice between epoxy and thermoplastic depends on specific application requirements, balancing mechanical performance with environmental resilience.

Applications in Aerospace and Automotive Industries

Epoxy carbon composites offer superior stiffness, strength, and thermal stability, making them ideal for high-performance aerospace components like aircraft fuselages and wing structures where durability under extreme conditions is critical. Thermoplastic carbon composites provide enhanced impact resistance, faster manufacturing cycles, and recyclability, favoring automotive applications such as structural parts and crash components that demand lightweight yet resilient materials. Aerospace relies heavily on epoxy composites for their long-term mechanical reliability, while the automotive industry increasingly adopts thermoplastic carbon composites to optimize production efficiency and sustainability.

Recyclability and Sustainability Factors

Epoxy carbon composites exhibit strong mechanical properties but face significant challenges in recyclability due to their thermoset nature, limiting reuse and contributing to landfill waste. Thermoplastic carbon composites offer enhanced sustainability through improved recyclability, enabling multiple reshaping and recycling cycles without significant loss of structural integrity. The choice between these materials impacts lifecycle environmental footprints, favoring thermoplastic composites for circular economy applications in industries like automotive and aerospace.

Future Trends in Carbon Composite Technology

Epoxy carbon composites exhibit superior mechanical strength and thermal stability, making them ideal for high-performance aerospace and automotive applications. Thermoplastic carbon composites offer enhanced recyclability and faster processing times, aligning with the increasing demand for sustainable manufacturing solutions. Future trends emphasize hybrid composites combining epoxy and thermoplastic matrices to balance performance, cost-efficiency, and environmental impact in next-generation carbon composite technology.

Epoxy Carbon Composite vs Thermoplastic Carbon Composite Infographic

materialdif.com

materialdif.com