Vapor-grown carbon fibers exhibit a higher surface area and enhanced electrical conductivity compared to conventional carbon fibers, making them ideal for advanced composite materials and energy storage applications. Their unique nanoscale structure provides superior mechanical strength and improved interface bonding with polymer matrices. These properties enable vapor-grown carbon fibers to deliver better performance in lightweight, high-strength, and conductive composites than traditional carbon fibers.

Table of Comparison

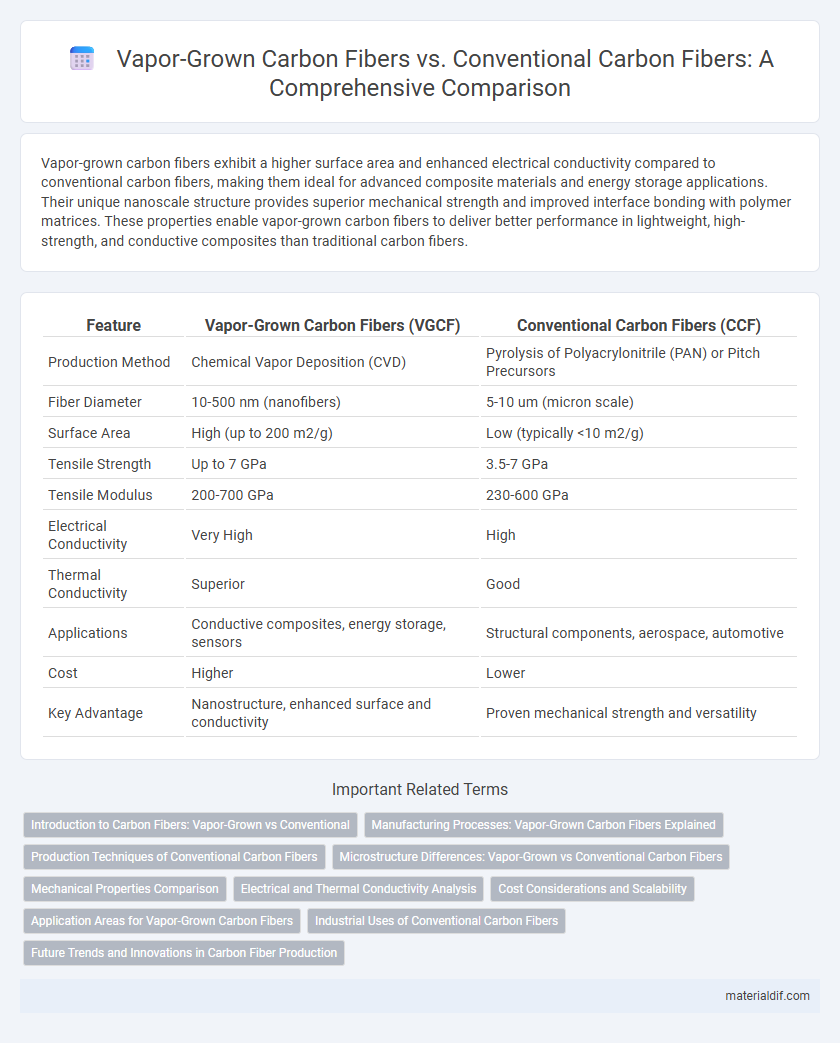

| Feature | Vapor-Grown Carbon Fibers (VGCF) | Conventional Carbon Fibers (CCF) |

|---|---|---|

| Production Method | Chemical Vapor Deposition (CVD) | Pyrolysis of Polyacrylonitrile (PAN) or Pitch Precursors |

| Fiber Diameter | 10-500 nm (nanofibers) | 5-10 um (micron scale) |

| Surface Area | High (up to 200 m2/g) | Low (typically <10 m2/g) |

| Tensile Strength | Up to 7 GPa | 3.5-7 GPa |

| Tensile Modulus | 200-700 GPa | 230-600 GPa |

| Electrical Conductivity | Very High | High |

| Thermal Conductivity | Superior | Good |

| Applications | Conductive composites, energy storage, sensors | Structural components, aerospace, automotive |

| Cost | Higher | Lower |

| Key Advantage | Nanostructure, enhanced surface and conductivity | Proven mechanical strength and versatility |

Introduction to Carbon Fibers: Vapor-Grown vs Conventional

Vapor-grown carbon fibers (VGCF) exhibit a unique morphology with high aspect ratios and surface areas, distinguishing them from conventional carbon fibers that are typically produced by pyrolyzing polyacrylonitrile (PAN) or pitch precursors. VGCFs demonstrate enhanced electrical conductivity and improved mechanical properties, making them ideal for advanced composites and thermal management applications. Conventional carbon fibers offer excellent tensile strength and stiffness, widely used in aerospace and automotive industries, but lack the nano-scale features present in vapor-grown variants.

Manufacturing Processes: Vapor-Grown Carbon Fibers Explained

Vapor-grown carbon fibers (VGCF) are produced through chemical vapor deposition (CVD), where hydrocarbon gases decompose on substrates at high temperatures, forming continuous carbon filaments with nanoscale diameters. This process allows precise control over fiber morphology, resulting in lightweight fibers with high surface area and enhanced conductivity compared to conventional carbon fibers manufactured by pyrolyzing polymer precursors like polyacrylonitrile (PAN). The CVD method enables scalable production of VGCFs tailored for advanced composite materials and energy storage applications due to their superior mechanical and electrochemical properties.

Production Techniques of Conventional Carbon Fibers

Conventional carbon fibers are primarily produced through a pyrolysis process that involves stabilizing precursor fibers, typically polyacrylonitrile (PAN), and then carbonizing them at high temperatures above 1000degC in an inert atmosphere. The stabilization phase chemically alters the fibers to withstand the carbonization step without melting, ensuring a high carbon content and structural integrity. This multi-stage process results in carbon fibers with high tensile strength and modulus, widely used in aerospace and automotive industries.

Microstructure Differences: Vapor-Grown vs Conventional Carbon Fibers

Vapor-grown carbon fibers exhibit a highly aligned graphitic microstructure with fewer defects compared to conventional carbon fibers, resulting in superior electrical conductivity and mechanical strength. The vapor deposition process promotes uniform nanoscale crystallite formation, while conventional fibers often contain more heterogeneous and disordered graphitic domains. These microstructural differences influence the fibers' tensile properties, thermal stability, and application performance in advanced composites.

Mechanical Properties Comparison

Vapor-grown carbon fibers (VGCF) exhibit superior mechanical properties compared to conventional carbon fibers, including higher tensile strength and improved modulus due to their unique nano-structured morphology. The increased surface area and reduced defect density in VGCF contribute to enhanced load transfer efficiency and fracture resistance in composite materials. These characteristics make VGCF particularly advantageous in applications requiring lightweight, high-performance mechanical components.

Electrical and Thermal Conductivity Analysis

Vapor-grown carbon fibers (VGCF) exhibit significantly higher electrical conductivity, reaching up to 10^4 S/m, compared to conventional carbon fibers which typically range between 10^2 to 10^3 S/m due to their unique graphitic structure and reduced defect density. VGCF also demonstrate superior thermal conductivity, often exceeding 300 W/m*K, surpassing the 150-200 W/m*K typically observed in conventional fibers, enabling enhanced heat dissipation in composite materials. The enhanced conductivity in VGCF is attributed to their smaller diameter and higher aspect ratio, which facilitate more efficient electron and phonon transport pathways.

Cost Considerations and Scalability

Vapor-grown carbon fibers exhibit lower production costs due to their energy-efficient chemical vapor deposition processes compared to the high-temperature pyrolysis used in conventional carbon fibers. Scalability is enhanced with vapor-grown fibers as their continuous manufacturing techniques allow for large-scale production without significant quality loss. Conventional carbon fibers face higher scalability challenges due to slower batch processing and expensive precursor materials like polyacrylonitrile (PAN).

Application Areas for Vapor-Grown Carbon Fibers

Vapor-grown carbon fibers (VGCF) are extensively used in advanced composite materials, offering superior electrical conductivity and thermal management in aerospace, automotive, and electronics industries. Their unique nanoscale diameter and high aspect ratio enhance mechanical strength and durability in battery electrodes and electromagnetic interference shielding applications. VGCF also play a crucial role in thermal interface materials and heat dissipation systems for high-performance electronic devices.

Industrial Uses of Conventional Carbon Fibers

Conventional carbon fibers are extensively used in aerospace, automotive, and sporting goods industries due to their high tensile strength, stiffness, and lightweight properties. These fibers contribute to manufacturing aircraft components, automotive parts, and high-performance sports equipment, enhancing durability and fuel efficiency. Industrial applications prioritize conventional carbon fibers for their consistent quality and established performance standards in composite materials.

Future Trends and Innovations in Carbon Fiber Production

Vapor-grown carbon fibers (VGCF) exhibit superior electrical conductivity and tensile strength compared to conventional carbon fibers, driving advancements in aerospace and electronics industries. Emerging trends focus on enhancing VGCF scalability and cost-efficiency through improved chemical vapor deposition techniques and sustainable precursor materials. Innovations such as hybrid fiber composites integrating VGCF promise to revolutionize lightweight, high-performance applications in automotive and renewable energy sectors.

Vapor-grown carbon fibers vs Conventional carbon fibers Infographic

materialdif.com

materialdif.com