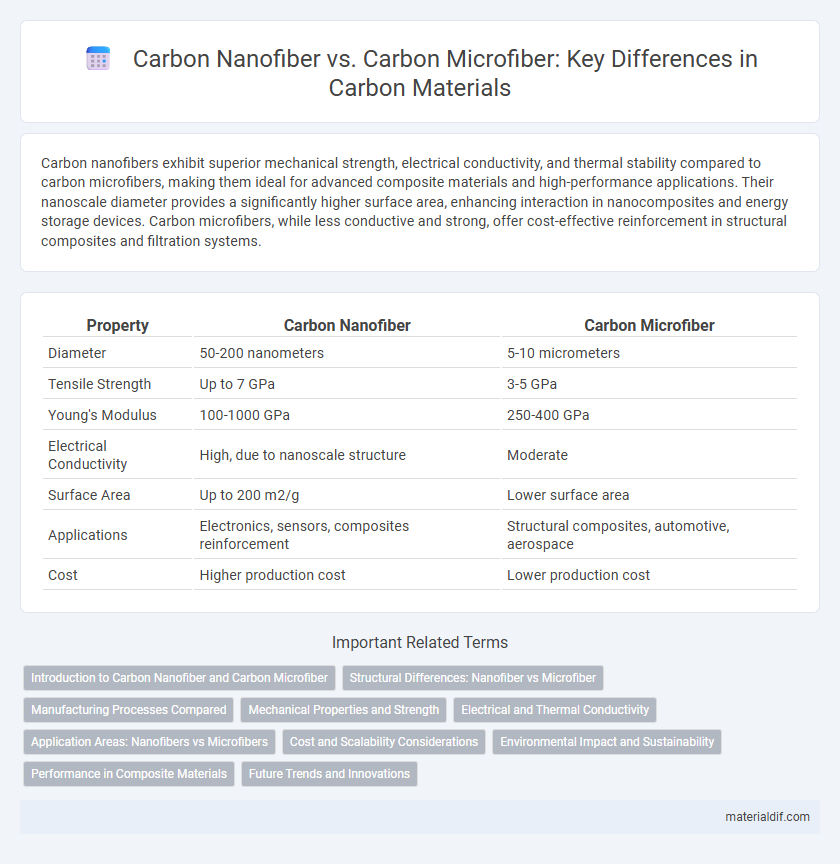

Carbon nanofibers exhibit superior mechanical strength, electrical conductivity, and thermal stability compared to carbon microfibers, making them ideal for advanced composite materials and high-performance applications. Their nanoscale diameter provides a significantly higher surface area, enhancing interaction in nanocomposites and energy storage devices. Carbon microfibers, while less conductive and strong, offer cost-effective reinforcement in structural composites and filtration systems.

Table of Comparison

| Property | Carbon Nanofiber | Carbon Microfiber |

|---|---|---|

| Diameter | 50-200 nanometers | 5-10 micrometers |

| Tensile Strength | Up to 7 GPa | 3-5 GPa |

| Young's Modulus | 100-1000 GPa | 250-400 GPa |

| Electrical Conductivity | High, due to nanoscale structure | Moderate |

| Surface Area | Up to 200 m2/g | Lower surface area |

| Applications | Electronics, sensors, composites reinforcement | Structural composites, automotive, aerospace |

| Cost | Higher production cost | Lower production cost |

Introduction to Carbon Nanofiber and Carbon Microfiber

Carbon nanofibers are cylindrical nanostructures with diameters typically below 100 nanometers, offering high tensile strength, electrical conductivity, and large surface area, making them ideal for advanced composites and electromagnetic applications. Carbon microfibers, larger in diameter ranging from 1 to 100 micrometers, provide enhanced mechanical properties and thermal stability at a more economical scale, commonly used in reinforcing materials and filtration systems. Both materials exhibit unique structural properties that influence their performance in aerospace, automotive, and energy storage industries.

Structural Differences: Nanofiber vs Microfiber

Carbon nanofibers exhibit diameters typically in the range of 50 to 200 nanometers, with a highly ordered graphitic structure that enhances mechanical strength and electrical conductivity compared to carbon microfibers, which generally measure between 1 to 10 micrometers. The smaller diameter and higher aspect ratio of nanofibers result in a greater surface area-to-volume ratio, providing superior interfacial bonding in composites. Carbon microfibers possess a more amorphous carbon structure with less uniformity, making them less effective in applications demanding high tensile strength and conductivity.

Manufacturing Processes Compared

Carbon nanofibers are typically manufactured using chemical vapor deposition (CVD) processes that allow precise control over fiber diameter and morphology at the nanoscale, resulting in fibers with diameters ranging from 50 to 200 nanometers. Carbon microfibers, on the other hand, are commonly produced through electrospinning or melt spinning, followed by stabilization and carbonization, yielding fibers with diameters in the micrometer range, generally between 1 and 10 micrometers. The CVD process for nanofibers enables high surface area and tailored structural properties, while the methods for microfibers focus on scalability and mechanical strength suitable for composite reinforcement.

Mechanical Properties and Strength

Carbon nanofibers exhibit superior mechanical properties and strength compared to carbon microfibers due to their smaller diameter and higher surface area, which enhance load transfer and interfacial bonding. Their tensile strength can reach up to 7 GPa, significantly outperforming carbon microfibers that typically have tensile strengths around 2-4 GPa. The nanoscale structure of carbon nanofibers also provides greater stiffness and flexibility, making them ideal for high-performance composite materials.

Electrical and Thermal Conductivity

Carbon nanofibers exhibit superior electrical conductivity compared to carbon microfibers due to their smaller diameter and higher aspect ratio, which facilitate efficient electron transport along the fibers. Thermal conductivity in carbon nanofibers is also enhanced, driven by their well-ordered graphitic structure and reduced phonon scattering at the nanoscale. In contrast, carbon microfibers, while still conductive, generally present lower electrical and thermal conductivities because of their larger size and increased structural defects.

Application Areas: Nanofibers vs Microfibers

Carbon nanofibers exhibit exceptional electrical conductivity and high surface area, making them ideal for energy storage devices, sensors, and advanced composites in aerospace and automotive industries. Carbon microfibers, with their superior mechanical strength and thermal stability, are predominantly used in structural reinforcement of composites, filtration systems, and heating elements. The nanoscale dimension of carbon nanofibers enables enhanced electrochemical performance, while microfibers provide bulk material strength and durability in industrial applications.

Cost and Scalability Considerations

Carbon nanofibers offer superior mechanical properties but come with significantly higher production costs and complex scalability challenges due to advanced manufacturing processes like chemical vapor deposition. In contrast, carbon microfibers are more cost-effective and easier to produce at large scales, making them suitable for bulk applications despite having lower strength-to-weight ratios. Industries aiming for mass production often prefer carbon microfibers to balance performance with economic feasibility.

Environmental Impact and Sustainability

Carbon nanofibers exhibit higher energy consumption during production compared to carbon microfibers, resulting in a larger carbon footprint. However, their enhanced mechanical properties contribute to longer product lifespans and potential material efficiency, reducing overall environmental impact. Carbon microfibers, with lower manufacturing emissions, offer better sustainability for large-scale applications but may require more frequent replacement due to lower durability.

Performance in Composite Materials

Carbon nanofibers exhibit superior mechanical strength and enhanced electrical conductivity compared to carbon microfibers, leading to improved load transfer and durability in composite materials. Their nanoscale diameter and high aspect ratio provide larger surface area for matrix bonding, resulting in composites with higher tensile strength and impact resistance. Carbon microfibers, while offering good stiffness and thermal stability, generally deliver lower performance enhancements due to their larger size and reduced interface interaction within the composite matrix.

Future Trends and Innovations

Future trends in carbon nanofiber technology emphasize enhanced electrical conductivity and increased surface area for energy storage applications, driving innovations in batteries and supercapacitors. Advances in carbon microfiber manufacturing target improved mechanical strength and lightweight composites for aerospace and automotive industries. Both materials see growing integration with nanotechnology and sustainable production methods to meet evolving performance and environmental demands.

Carbon nanofiber vs Carbon microfiber Infographic

materialdif.com

materialdif.com