Carbon black consists of fine particles primarily used as a reinforcing agent in rubber and as a pigment, offering high surface area and excellent UV protection. Carbon graphite, in contrast, features a crystalline structure with layers of carbon atoms arranged in hexagonal patterns, providing exceptional electrical conductivity and thermal resistance. While carbon black enhances durability and color depth, carbon graphite is preferred for its lubricating properties and strength in high-temperature applications.

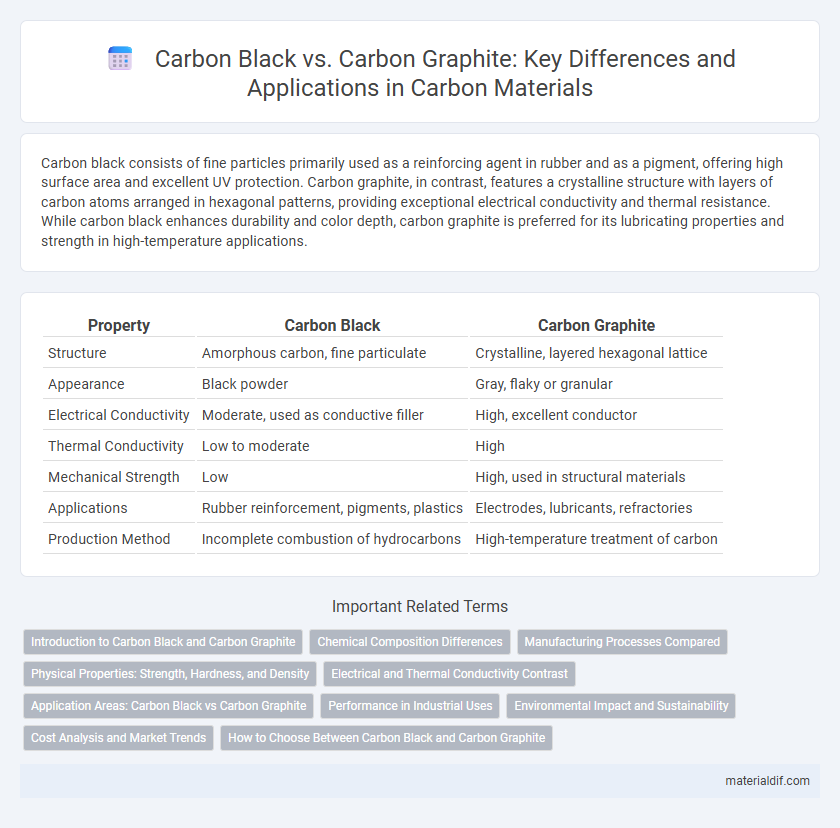

Table of Comparison

| Property | Carbon Black | Carbon Graphite |

|---|---|---|

| Structure | Amorphous carbon, fine particulate | Crystalline, layered hexagonal lattice |

| Appearance | Black powder | Gray, flaky or granular |

| Electrical Conductivity | Moderate, used as conductive filler | High, excellent conductor |

| Thermal Conductivity | Low to moderate | High |

| Mechanical Strength | Low | High, used in structural materials |

| Applications | Rubber reinforcement, pigments, plastics | Electrodes, lubricants, refractories |

| Production Method | Incomplete combustion of hydrocarbons | High-temperature treatment of carbon |

Introduction to Carbon Black and Carbon Graphite

Carbon black is a fine black powder composed primarily of elemental carbon, produced by incomplete combustion of heavy petroleum products, and widely used as a reinforcing filler in rubber and as a pigment. Carbon graphite consists of layers of carbon atoms arranged in a hexagonal lattice, exhibiting high electrical conductivity, thermal stability, and lubricity, commonly utilized in electrodes, lubricants, and refractories. Both materials differ significantly in structure and applications, with carbon black offering high surface area and carbon graphite providing excellent mechanical strength and conductivity.

Chemical Composition Differences

Carbon black consists primarily of elemental carbon in the form of fine particles with a high surface area, produced by incomplete combustion of hydrocarbons. Graphite is a crystalline allotrope of carbon characterized by layers of hexagonally arranged carbon atoms bonded covalently within planes and weakly between planes. The chemical composition difference lies in carbon black's amorphous structure versus graphite's ordered, crystalline lattice.

Manufacturing Processes Compared

Carbon black is produced through the incomplete combustion of heavy petroleum products in a controlled furnace process, resulting in fine, particulate carbon used mainly as a reinforcing filler in rubber products. Carbon graphite manufacturing involves high-temperature treatment of carbon materials, such as petroleum coke or coal tar pitch, in electric furnaces, leading to a crystalline structure with excellent electrical and thermal conductivity. The key difference lies in carbon black's formation as amorphous carbon particles via combustion, whereas carbon graphite undergoes graphitization through solid-state transformations at temperatures above 2500degC.

Physical Properties: Strength, Hardness, and Density

Carbon black exhibits high strength and excellent hardness with a typical density around 1.8 to 2.1 g/cm3, making it ideal for reinforcing rubber and plastic composites. Graphite, in contrast, possesses lower strength but superior hardness due to its layered crystal structure, with a density typically between 2.2 to 2.3 g/cm3. The anisotropic nature of graphite imparts high mechanical stability along the planes, while carbon black's amorphous structure provides versatility in applications requiring impact resistance.

Electrical and Thermal Conductivity Contrast

Carbon black exhibits low electrical and thermal conductivity due to its amorphous structure and high surface area, making it suitable for applications requiring electrical insulation or reinforcement. In contrast, carbon graphite demonstrates high electrical and thermal conductivity attributed to its crystalline, layered structure, which facilitates efficient electron and phonon transport. This conductivity contrast drives the selection of carbon black for insulating fillers and carbon graphite for conductive components in electronics and heat dissipation systems.

Application Areas: Carbon Black vs Carbon Graphite

Carbon black is widely used in rubber reinforcement, particularly in tires and conveyor belts, providing enhanced durability and abrasion resistance. In contrast, carbon graphite excels in high-temperature applications such as electrodes, lubricants, and refractory materials due to its excellent thermal conductivity and chemical stability. Both materials play crucial roles in industrial manufacturing, but their distinct properties determine their specific applications in sectors like automotive, chemical processing, and electronics.

Performance in Industrial Uses

Carbon black exhibits superior reinforcement and conductivity, making it ideal for applications like rubber manufacturing and conductive polymers. Carbon graphite offers exceptional thermal stability and lubricity, enhancing performance in high-temperature industries and mechanical components. Both materials excel in distinct industrial roles by leveraging their unique structural properties for optimized performance.

Environmental Impact and Sustainability

Carbon black, derived primarily from the incomplete combustion of heavy petroleum products, contributes significantly to air pollution and greenhouse gas emissions, impacting urban air quality and climate change. In contrast, carbon graphite, often sourced from natural mineral deposits or synthetic processes, exhibits lower environmental footprints due to its longer lifespan and recyclability in applications such as batteries and lubricants. Sustainable practices in carbon graphite production, including the use of renewable energy and improved material recovery techniques, further enhance its eco-friendly profile compared to carbon black's more pollutive manufacturing processes.

Cost Analysis and Market Trends

Carbon black maintains a lower production cost due to its simpler manufacturing process compared to carbon graphite, which requires high-temperature treatment and graphitization. Market trends indicate rising demand for carbon black in rubber and tire industries, driven by automotive growth, while carbon graphite is gaining traction in energy storage and aerospace sectors due to its superior conductivity and strength. Cost analysis reveals carbon graphite's higher price point justifies its specialized applications despite carbon black's dominance in volume-driven markets.

How to Choose Between Carbon Black and Carbon Graphite

Choosing between carbon black and carbon graphite depends on the application's requirements for conductivity, thermal stability, and mechanical strength. Carbon black offers excellent electrical conductivity and pigmentation properties, making it ideal for rubber reinforcement and conductive plastics, while carbon graphite excels in high-temperature environments due to its superior thermal resistance and lubricating characteristics. Consider the operating temperature range, electrical conductivity needs, and mechanical performance when selecting the optimal carbon material for your project.

Carbon black vs Carbon graphite Infographic

materialdif.com

materialdif.com