Carbon paper transfers ink onto surfaces through direct pressure, making it ideal for creating duplicates in handwritten or typed documents. Carbon film, a thin layer of carbon material, is primarily used in electronic applications for its conductive and durable properties. While carbon paper is disposable and designed for manual use, carbon film offers long-lasting performance in devices such as batteries and sensors.

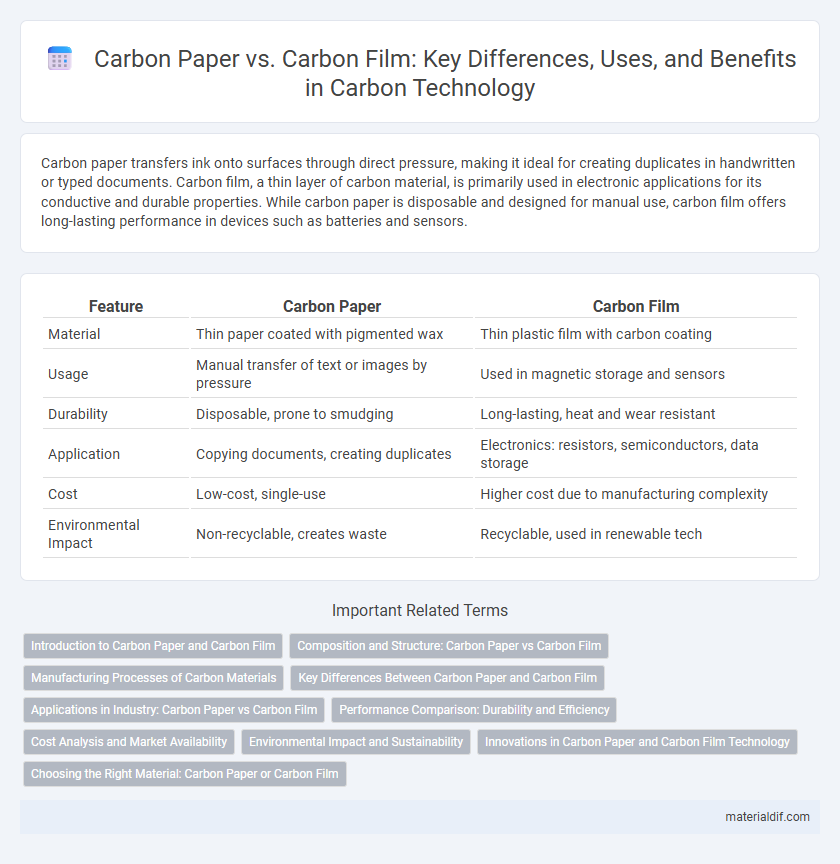

Table of Comparison

| Feature | Carbon Paper | Carbon Film |

|---|---|---|

| Material | Thin paper coated with pigmented wax | Thin plastic film with carbon coating |

| Usage | Manual transfer of text or images by pressure | Used in magnetic storage and sensors |

| Durability | Disposable, prone to smudging | Long-lasting, heat and wear resistant |

| Application | Copying documents, creating duplicates | Electronics: resistors, semiconductors, data storage |

| Cost | Low-cost, single-use | Higher cost due to manufacturing complexity |

| Environmental Impact | Non-recyclable, creates waste | Recyclable, used in renewable tech |

Introduction to Carbon Paper and Carbon Film

Carbon paper consists of a paper sheet coated with a layer of dry ink or pigmented film that transfers markings when pressure is applied, commonly used for making duplicate handwritten or typed documents. Carbon film, by contrast, is an ultra-thin polymeric layer of carbon atoms deposited on surfaces in semiconductor manufacturing, providing conductive or protective properties due to its uniform structure. Both materials utilize carbon's conductive and adhesive qualities but serve distinct roles in document duplication and electronics industries, respectively.

Composition and Structure: Carbon Paper vs Carbon Film

Carbon paper consists of a paper base coated with a layer of loosely bound pigmented wax or ink containing carbon particles, designed to transfer writing by pressure. Carbon film, used primarily in electronics, is a thin, uniform layer of carbon atoms deposited on a substrate, often via sputtering or chemical vapor deposition, providing conductive properties. The structure of carbon film offers greater consistency and durability compared to the porous and flexible composition of carbon paper.

Manufacturing Processes of Carbon Materials

Carbon paper manufacturing involves coating a sheet of paper with a layer of dry ink, typically composed of carbon black and wax, using processes such as roller coating or gravure printing to ensure uniform ink distribution. In contrast, carbon film is produced through chemical vapor deposition (CVD) or sputtering techniques, where carbon atoms form a thin, uniform layer on substrates like silicon wafers or glass, enabling precise control over thickness and material properties. The choice between carbon paper and carbon film depends on the intended application, with carbon film offering superior conductivity and durability for electronic components, while carbon paper remains cost-effective for duplicating documents.

Key Differences Between Carbon Paper and Carbon Film

Carbon paper transfers ink through direct pressure, making it suitable for creating duplicate handwritten or typed documents, while carbon film uses a thin, ink-coated polyester layer bonded to a substrate, commonly applied in graphics and printing industries. Carbon paper is a single-use medium that produces immediate copies but can smudge or fade over time, whereas carbon film offers higher durability, consistent image quality, and resistance to environmental factors. The primary distinction lies in application: carbon paper excels in manual duplication processes, whereas carbon film is optimized for industrial and commercial print production.

Applications in Industry: Carbon Paper vs Carbon Film

Carbon paper is widely used in industrial settings for creating duplicate documents like invoices, receipts, and order forms due to its simplicity and cost-efficiency. Carbon film, favored in manufacturing and electronics industries, serves as a key material in sensors, batteries, and coatings because of its thin, uniform layer and superior electrical conductivity. While carbon paper excels in document replication tasks, carbon film's versatility and performance in high-tech applications make it indispensable in advanced industrial processes.

Performance Comparison: Durability and Efficiency

Carbon paper offers moderate durability suitable for short-term use, while carbon film provides superior longevity due to its robust synthetic composition. In terms of efficiency, carbon film ensures consistent image transfer with less degradation over time, enhancing print quality and reliability. The enhanced durability and sustained performance of carbon film make it a preferred choice for high-volume or precision-dependent applications.

Cost Analysis and Market Availability

Carbon paper generally presents a lower cost option due to its simple production process and widespread manufacturing across various suppliers, making it readily available in most office and art supply markets. Carbon film, often used in industrial applications and specialized electronics, commands a higher price due to advanced material composition and limited production scale, resulting in comparatively selective market availability. The cost difference influences consumer choice, with carbon paper preferred for budget-conscious buyers and carbon film favored for performance-critical uses where durability justifies the expense.

Environmental Impact and Sustainability

Carbon paper generates significant waste after single use, contributing to deforestation and landfill problems due to its non-recyclable materials. Carbon film, made with thin plastic layers and conductive materials, offers improved efficiency but poses challenges in recycling and microplastic pollution. Sustainable alternatives focus on biodegradable materials and digital solutions to reduce environmental impact and promote long-term sustainability.

Innovations in Carbon Paper and Carbon Film Technology

Innovations in carbon paper technology have enhanced the quality of transfers by integrating micro-encapsulated dyes and pressure-sensitive layers, resulting in clearer, longer-lasting impressions. Advances in carbon film technology focus on developing ultra-thin, conductive films using graphene and carbon nanotubes, improving flexibility and electrical conductivity for applications in electronics and flexible displays. Both technologies continue to evolve through nanotechnology and eco-friendly materials, driving enhanced performance and sustainability in printing and electronic industries.

Choosing the Right Material: Carbon Paper or Carbon Film

Choosing the right material between carbon paper and carbon film depends on the specific application requirements, such as durability, flexibility, and conductivity. Carbon paper excels in creating instant copies through pressure transfer, making it ideal for manual note duplication and receipt generation, while carbon film offers consistent electrical conductivity suitable for electronic components and sensors. Understanding the performance characteristics and intended use ensures optimal selection of carbon-based materials for both traditional and modern applications.

Carbon Paper vs Carbon Film Infographic

materialdif.com

materialdif.com