Vitreous carbon offers a dense, non-porous structure with exceptional chemical resistance and high thermal stability, ideal for applications demanding inert surfaces and durability. Reticulated carbon provides a highly porous, sponge-like framework that excels in filtration, catalysis, and energy storage due to its large surface area and excellent fluid permeability. Each type of carbon suits specific industrial uses based on structural and functional properties essential for optimizing performance.

Table of Comparison

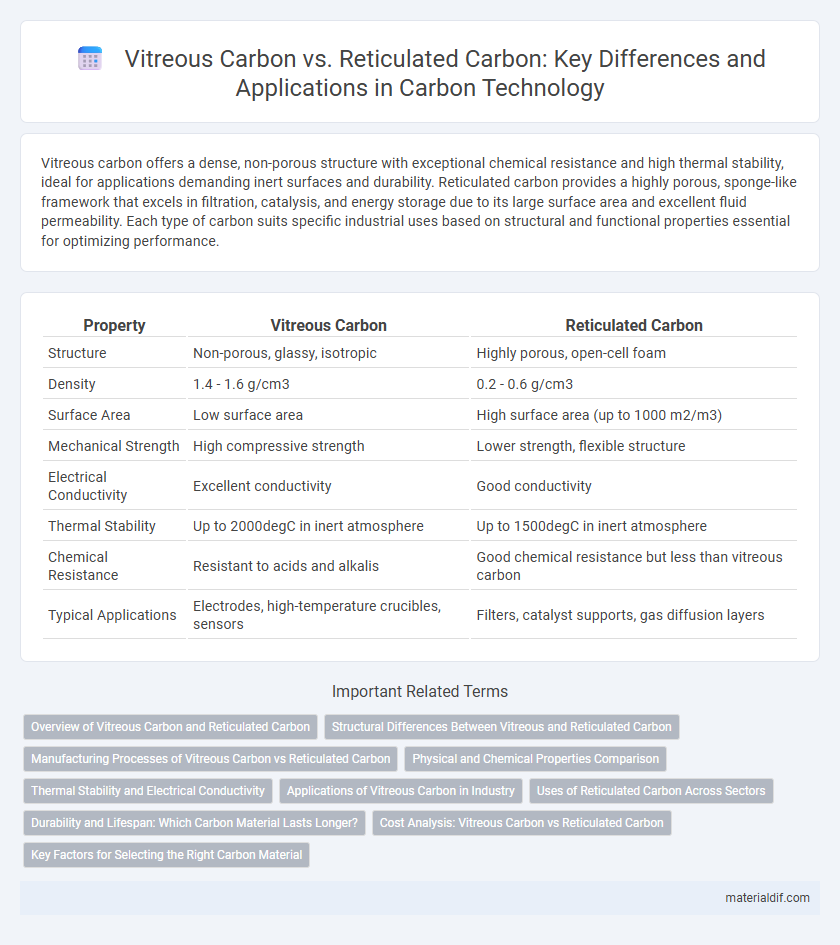

| Property | Vitreous Carbon | Reticulated Carbon |

|---|---|---|

| Structure | Non-porous, glassy, isotropic | Highly porous, open-cell foam |

| Density | 1.4 - 1.6 g/cm3 | 0.2 - 0.6 g/cm3 |

| Surface Area | Low surface area | High surface area (up to 1000 m2/m3) |

| Mechanical Strength | High compressive strength | Lower strength, flexible structure |

| Electrical Conductivity | Excellent conductivity | Good conductivity |

| Thermal Stability | Up to 2000degC in inert atmosphere | Up to 1500degC in inert atmosphere |

| Chemical Resistance | Resistant to acids and alkalis | Good chemical resistance but less than vitreous carbon |

| Typical Applications | Electrodes, high-temperature crucibles, sensors | Filters, catalyst supports, gas diffusion layers |

Overview of Vitreous Carbon and Reticulated Carbon

Vitreous carbon is a hard, glass-like material known for its high thermal stability, chemical resistance, and low density, making it ideal for applications in electrochemistry and high-temperature environments. Reticulated carbon consists of a porous, foam-like structure with a high surface area, commonly used for filtration, catalyst supports, and gas diffusion layers. Both types leverage carbon's exceptional conductivity and durability but differ significantly in morphology and typical industrial uses.

Structural Differences Between Vitreous and Reticulated Carbon

Vitreous carbon is characterized by a dense, glass-like structure with low porosity, providing high mechanical strength and chemical resistance. Reticulated carbon, in contrast, features an open-cell foam structure with interconnected pores, enabling high surface area and excellent permeability. These structural differences make vitreous carbon suitable for precision applications requiring durability, while reticulated carbon excels in filtration and catalyst support due to its porous framework.

Manufacturing Processes of Vitreous Carbon vs Reticulated Carbon

Vitreous carbon is manufactured through carbonization of polymeric precursors at high temperatures in an inert atmosphere, resulting in a non-porous, glass-like structure with high density and hardness. Reticulated carbon is produced using a polymer or resin foam template that undergoes pyrolysis, forming an open-cell porous network with high surface area and low density. The key distinction lies in vitreous carbon's dense, isotropic structure formed via controlled thermal decomposition, while reticulated carbon's morphology is derived from sacrificial foam templates yielding a 3D porous matrix.

Physical and Chemical Properties Comparison

Vitreous carbon exhibits high density, low porosity, and superior chemical inertness, making it highly resistant to oxidation and corrosion at elevated temperatures. Reticulated carbon, characterized by its porous, foam-like structure, offers a high surface area and excellent electrical conductivity but is more susceptible to oxidation due to increased reactivity from its open framework. The distinct microstructures result in vitreous carbon being optimal for applications requiring mechanical strength and chemical stability, while reticulated carbon excels in catalysis and filtration where surface area is critical.

Thermal Stability and Electrical Conductivity

Vitreous carbon exhibits exceptional thermal stability, maintaining structural integrity at temperatures exceeding 2,000degC in inert atmospheres, making it ideal for high-temperature applications. Reticulated carbon, with its porous structure, offers superior electrical conductivity due to increased surface area, enhancing electron transfer in electrochemical devices. Both forms differ significantly: vitreous carbon excels in thermal resistance while reticulated carbon provides enhanced electrical performance through its interconnected network.

Applications of Vitreous Carbon in Industry

Vitreous carbon is extensively used in electrochemical applications due to its high chemical resistance, low porosity, and excellent electrical conductivity, making it ideal for electrodes and sensors in fuel cells and batteries. Its thermal stability and inertness allow use in harsh industrial environments, including high-temperature furnace components and chemical reactors. Additionally, vitreous carbon serves as a robust material for semiconductor manufacturing and microfabrication processes, where precision and durability are critical.

Uses of Reticulated Carbon Across Sectors

Reticulated carbon, known for its high porosity and excellent electrical conductivity, is widely used in energy storage devices such as batteries and supercapacitors, enabling efficient charge transfer and storage. Its open-cell foam structure also facilitates applications in filtration and catalysis, particularly in chemical and environmental sectors for gas purification and water treatment. Furthermore, reticulated carbon's lightweight and durable properties make it suitable for aerospace and automotive industries where high-performance materials are essential.

Durability and Lifespan: Which Carbon Material Lasts Longer?

Vitreous carbon demonstrates superior durability and longer lifespan compared to reticulated carbon due to its non-porous, glass-like structure that resists wear, corrosion, and thermal shock more effectively. Reticulated carbon, characterized by its porous and foam-like morphology, is more susceptible to mechanical degradation and chemical attack, limiting its longevity in harsh environments. For applications demanding extended service life and consistent performance, vitreous carbon remains the preferred choice.

Cost Analysis: Vitreous Carbon vs Reticulated Carbon

Vitreous carbon typically incurs higher production costs due to its dense, non-porous structure and complex manufacturing process involving pyrolysis, whereas reticulated carbon offers a cost-effective alternative with a porous, foam-like morphology enabling efficient material use and lower fabrication expenses. The initial investment for vitreous carbon components is justified in applications demanding superior chemical resistance and mechanical strength, while reticulated carbon suits budget-sensitive projects emphasizing high surface area and low weight. Evaluating total lifecycle costs reveals reticulated carbon's advantage in reduced maintenance and replacement expenses, which can offset its relatively lower upfront price compared to vitreous carbon.

Key Factors for Selecting the Right Carbon Material

Vitreous carbon offers high chemical resistance and excellent thermal stability, making it ideal for applications requiring durability in harsh environments. Reticulated carbon provides superior porosity and high surface area, which enhances catalytic efficiency and gas diffusion in filtration or electrode applications. Selecting the right carbon material depends on factors like structural integrity, porosity requirements, and operating temperature ranges.

Vitreous Carbon vs Reticulated Carbon Infographic

materialdif.com

materialdif.com