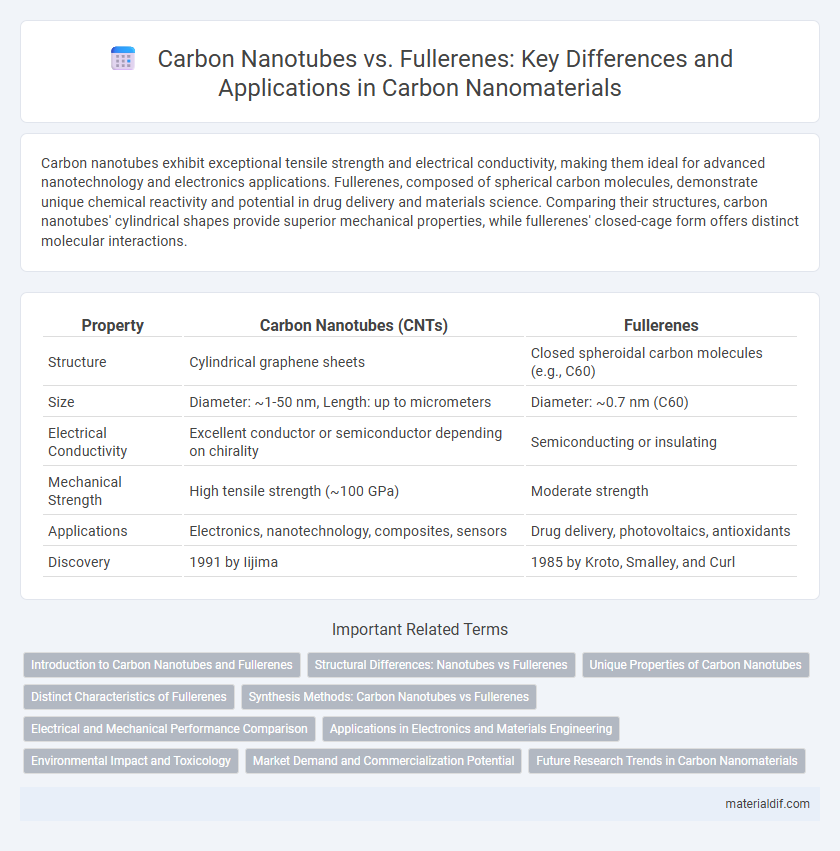

Carbon nanotubes exhibit exceptional tensile strength and electrical conductivity, making them ideal for advanced nanotechnology and electronics applications. Fullerenes, composed of spherical carbon molecules, demonstrate unique chemical reactivity and potential in drug delivery and materials science. Comparing their structures, carbon nanotubes' cylindrical shapes provide superior mechanical properties, while fullerenes' closed-cage form offers distinct molecular interactions.

Table of Comparison

| Property | Carbon Nanotubes (CNTs) | Fullerenes |

|---|---|---|

| Structure | Cylindrical graphene sheets | Closed spheroidal carbon molecules (e.g., C60) |

| Size | Diameter: ~1-50 nm, Length: up to micrometers | Diameter: ~0.7 nm (C60) |

| Electrical Conductivity | Excellent conductor or semiconductor depending on chirality | Semiconducting or insulating |

| Mechanical Strength | High tensile strength (~100 GPa) | Moderate strength |

| Applications | Electronics, nanotechnology, composites, sensors | Drug delivery, photovoltaics, antioxidants |

| Discovery | 1991 by Iijima | 1985 by Kroto, Smalley, and Curl |

Introduction to Carbon Nanotubes and Fullerenes

Carbon nanotubes consist of cylindrical nanostructures formed from graphene sheets rolled into tubes, exhibiting exceptional mechanical strength, electrical conductivity, and thermal stability. Fullerenes are spherical or ellipsoidal molecules composed entirely of carbon atoms arranged in hexagonal and pentagonal patterns, with C60 being the most common form. Both carbon nanotubes and fullerenes belong to the fullerene family but differ significantly in shape and applications, impacting fields like nanotechnology, electronics, and materials science.

Structural Differences: Nanotubes vs Fullerenes

Carbon nanotubes consist of cylindrical structures formed by rolled graphene sheets with hexagonal carbon atom arrangements, providing high aspect ratios and exceptional tensile strength. In contrast, fullerenes are spherical or ellipsoidal molecules composed of hexagonal and pentagonal carbon rings, creating closed-cage structures that resemble soccer balls. The key structural difference lies in nanotubes' elongated, hollow tubes versus fullerenes' compact, closed-surface geometry, influencing their electrical, mechanical, and chemical properties.

Unique Properties of Carbon Nanotubes

Carbon nanotubes exhibit exceptional mechanical strength, electrical conductivity, and thermal stability compared to fullerenes, due to their cylindrical nanostructure composed of sp2-bonded carbon atoms. These properties enable carbon nanotubes to outperform fullerenes in applications such as nanoelectronics, reinforced composites, and energy storage devices. Their high aspect ratio and extraordinary tensile strength make them ideal for use in advanced materials requiring both lightweight and robust characteristics.

Distinct Characteristics of Fullerenes

Fullerenes are unique carbon allotropes characterized by their closed-cage, spherical structure composed of hexagonal and pentagonal carbon rings, distinct from the cylindrical shape of carbon nanotubes. These molecules exhibit remarkable electron-accepting properties and high symmetry, enabling applications in organic photovoltaics and medicinal chemistry. Fullerenes' ability to form stable, soluble derivatives contrasts with the typically insoluble nature of carbon nanotubes, expanding their versatility in chemical and material science.

Synthesis Methods: Carbon Nanotubes vs Fullerenes

Chemical vapor deposition (CVD) is a predominant synthesis method for carbon nanotubes, enabling controlled growth on substrates through hydrocarbon decomposition at high temperatures. Fullerenes are primarily produced using arc discharge techniques, where carbon vapor condenses into spherical molecules after graphite electrodes are vaporized. Both methods yield distinct carbon allotropes with unique properties influenced by variations in temperature, pressure, and catalyst presence.

Electrical and Mechanical Performance Comparison

Carbon nanotubes exhibit superior electrical conductivity compared to fullerenes due to their extended cylindrical structure that facilitates electron transport along the tube axis. Mechanically, carbon nanotubes demonstrate exceptional tensile strength and flexibility, outperforming fullerenes which possess a spherical shape limiting their load-bearing capacity. The distinct atomic arrangements in carbon nanotubes enable enhanced electron mobility and structural resilience, making them ideal for advanced nanotechnology applications.

Applications in Electronics and Materials Engineering

Carbon nanotubes exhibit exceptional electrical conductivity and mechanical strength, making them ideal for advanced electronic components such as transistors, sensors, and flexible displays. Fullerenes, with their unique spherical structure, are primarily utilized in organic photovoltaics, superconductors, and drug delivery systems due to their electron-accepting properties. Both nanomaterials significantly enhance materials engineering by providing lightweight, resilient solutions for next-generation electronic and composite devices.

Environmental Impact and Toxicology

Carbon nanotubes exhibit greater environmental persistence and potential bioaccumulation compared to fullerenes, raising concerns about long-term ecological effects. Toxicological studies indicate that carbon nanotubes may induce more severe respiratory and cellular damage due to their fibrous shape and high aspect ratio, whereas fullerenes generally demonstrate lower toxicity but can generate reactive oxygen species under specific conditions. Understanding these differences is crucial for safe applications and regulatory policies addressing carbon nanomaterials.

Market Demand and Commercialization Potential

Carbon nanotubes exhibit higher market demand and commercialization potential than fullerenes due to their superior electrical conductivity, mechanical strength, and versatility in electronics, energy storage, and composite materials. Fullerenes, while valuable in medical and pharmaceutical research, face limitations in large-scale production and integration, hindering widespread commercial adoption. Advanced manufacturing techniques and growing applications in nanotechnology boost the carbon nanotube market growth, making them a preferred choice for industrial innovation.

Future Research Trends in Carbon Nanomaterials

Carbon nanotubes exhibit exceptional electrical conductivity and mechanical strength, making them ideal candidates for next-generation nanoelectronics and composite materials. Fullerenes offer unique electron affinity and photophysical properties that hold promise for advanced organic photovoltaics and drug delivery systems. Future research trends are converging on hybrid nanostructures combining carbon nanotubes and fullerenes to harness synergistic effects for enhanced energy storage and catalytic applications.

Carbon Nanotubes vs Fullerenes Infographic

materialdif.com

materialdif.com