Carbon composites consist of carbon fibers embedded in a resin matrix, offering superior strength-to-weight ratios and enhanced flexibility for aerospace and automotive applications. In contrast, carbon monoliths are solid blocks of carbon material that provide exceptional thermal conductivity and mechanical stability but lack the lightweight benefits of composites. Choosing between carbon composite and carbon monolith depends on the specific performance requirements, such as weight reduction versus durability and thermal management.

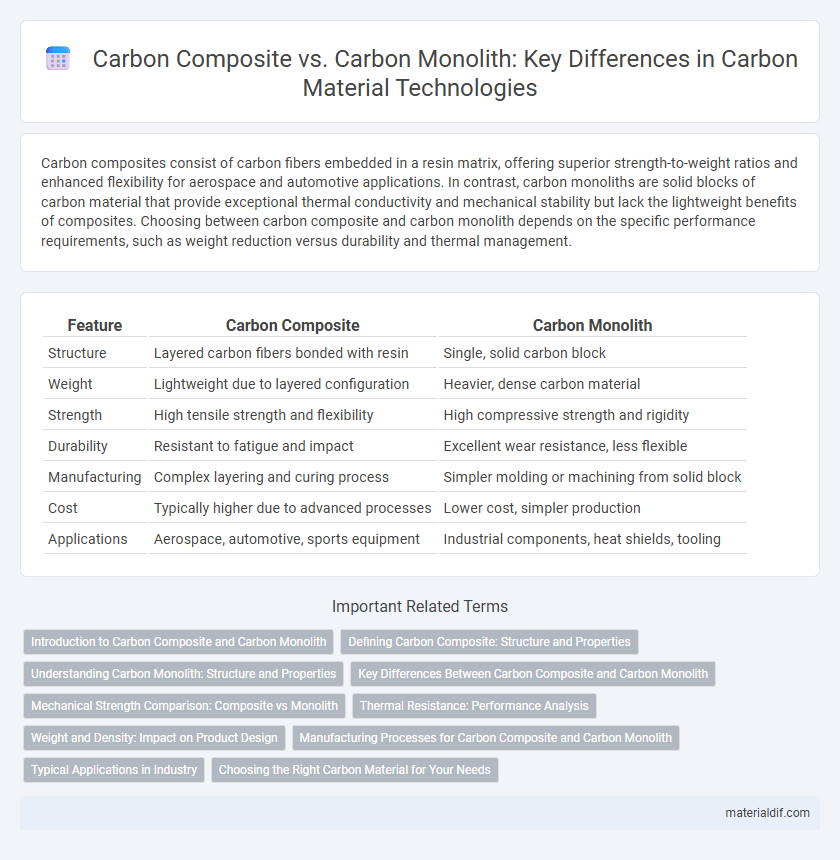

Table of Comparison

| Feature | Carbon Composite | Carbon Monolith |

|---|---|---|

| Structure | Layered carbon fibers bonded with resin | Single, solid carbon block |

| Weight | Lightweight due to layered configuration | Heavier, dense carbon material |

| Strength | High tensile strength and flexibility | High compressive strength and rigidity |

| Durability | Resistant to fatigue and impact | Excellent wear resistance, less flexible |

| Manufacturing | Complex layering and curing process | Simpler molding or machining from solid block |

| Cost | Typically higher due to advanced processes | Lower cost, simpler production |

| Applications | Aerospace, automotive, sports equipment | Industrial components, heat shields, tooling |

Introduction to Carbon Composite and Carbon Monolith

Carbon composite materials consist of carbon fibers embedded in a matrix, offering high strength-to-weight ratios and excellent durability, making them ideal for aerospace and automotive applications. Carbon monoliths are solid carbon structures with uniform properties, commonly used in high-temperature environments due to their thermal stability and resistance to wear. Understanding the differences between carbon composite and carbon monolith helps optimize material selection for specific engineering and industrial uses.

Defining Carbon Composite: Structure and Properties

Carbon composite consists of carbon fibers embedded in a polymer matrix, providing exceptional strength-to-weight ratio and enhanced flexibility compared to monolithic carbon materials. Its layered structure allows for improved impact resistance and tailored mechanical properties, making it ideal for aerospace and automotive applications. Unlike carbon monolith, which is a single solid piece, carbon composite offers superior fatigue resistance and enhanced durability under dynamic loads.

Understanding Carbon Monolith: Structure and Properties

Carbon monoliths consist of a continuous, solid carbon matrix providing high mechanical strength and thermal conductivity, unlike carbon composites that combine carbon fibers with a resin matrix. Their dense, uniform structure results in superior electrical conductivity and enhanced resistance to chemical corrosion, making them ideal for applications in energy storage and filtration systems. Carbon monoliths feature customizable pore sizes and high surface area, enabling efficient adsorption and catalytic processes in industrial uses.

Key Differences Between Carbon Composite and Carbon Monolith

Carbon composites consist of carbon fibers embedded within a resin matrix, offering high strength-to-weight ratios and enhanced flexibility for diverse engineering applications. Carbon monoliths are solid, uniform structures of carbon that provide superior thermal conductivity and mechanical strength but lack the adaptability of composite materials. The key differences lie in their structural composition, mechanical properties, and suitability for applications requiring either lightweight flexibility or solid durability.

Mechanical Strength Comparison: Composite vs Monolith

Carbon composites exhibit superior mechanical strength compared to carbon monoliths due to their layered structure and fiber reinforcement, which enhance tensile strength and impact resistance. The anisotropic nature of composites allows for tailored strength along specific directions, whereas carbon monoliths show uniform but generally lower mechanical performance. Studies indicate that carbon composites can achieve up to 30-40% higher tensile strength and improved fracture toughness relative to monolithic carbon materials.

Thermal Resistance: Performance Analysis

Carbon composites exhibit superior thermal resistance compared to carbon monoliths due to their heterogeneous microstructure, which disrupts heat transfer pathways and reduces thermal conductivity. The layered arrangement in carbon composites enhances thermal shock resistance, making them ideal for high-temperature applications where rapid temperature changes occur. In contrast, carbon monoliths, with their homogeneous structure, tend to have higher thermal conductivity but lower resistance to thermal cycling and mechanical stress under heat.

Weight and Density: Impact on Product Design

Carbon composites offer significantly lower density compared to carbon monoliths, resulting in lighter products without compromising strength. This weight reduction influences product design by enabling more aerodynamic shapes and improved fuel efficiency in automotive and aerospace industries. Engineers leverage the superior strength-to-weight ratio of carbon composites to innovate lightweight, high-performance structures.

Manufacturing Processes for Carbon Composite and Carbon Monolith

Carbon composite manufacturing involves layering carbon fibers with resin matrices, followed by curing through heat and pressure in autoclaves or molds to form lightweight, high-strength structures. Carbon monolith production typically requires controlled pyrolysis of carbon-rich precursors, such as polymers or pitch, at high temperatures to achieve a dense, homogenous carbon block with minimal defects. These distinct manufacturing processes impact the material's microstructure, mechanical properties, and suitability for applications in aerospace, automotive, and energy storage industries.

Typical Applications in Industry

Carbon composites find extensive use in aerospace and automotive industries due to their high strength-to-weight ratio and corrosion resistance, ideal for structural components and lightweight parts. Carbon monoliths are typically employed in high-temperature applications such as furnace linings, catalytic converter components, and electrode materials in steel manufacturing. The distinction in thermal stability and mechanical properties dictates their selection based on specific industrial requirements.

Choosing the Right Carbon Material for Your Needs

Carbon composites offer superior strength-to-weight ratios and enhanced flexibility, making them ideal for aerospace and automotive applications requiring lightweight yet durable materials. Carbon monoliths, characterized by their uniform structure and high thermal conductivity, are preferred in industrial processes needing consistent performance under extreme temperatures. Selecting the right carbon material depends on balancing mechanical properties, thermal performance, and specific application demands to optimize efficiency and longevity.

Carbon Composite vs Carbon Monolith Infographic

materialdif.com

materialdif.com