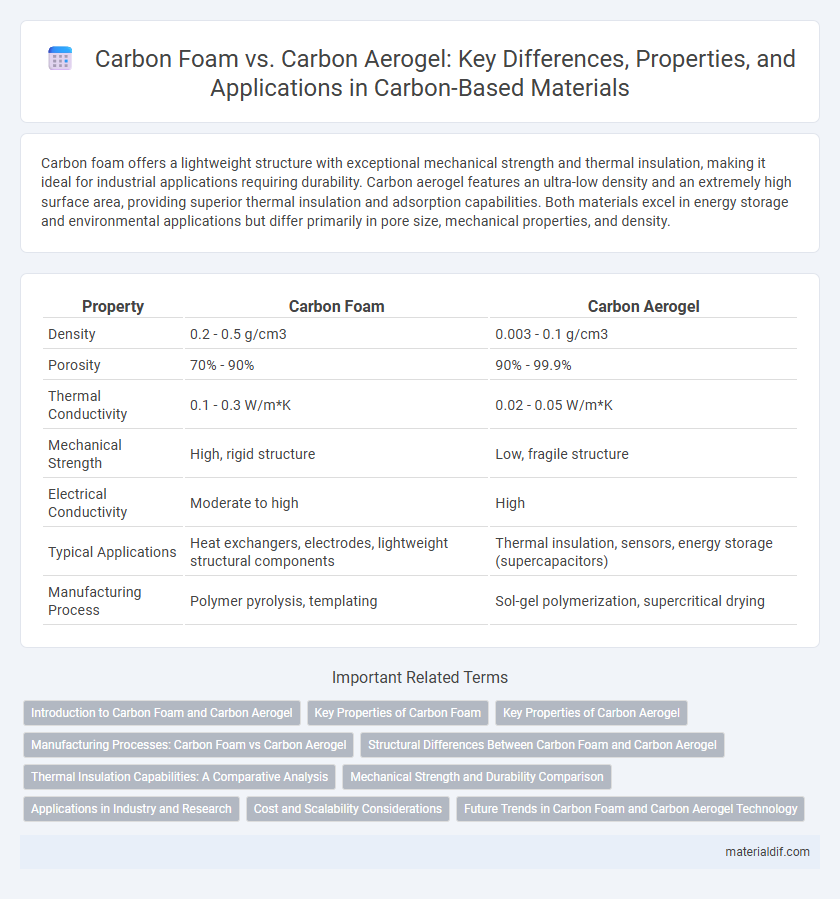

Carbon foam offers a lightweight structure with exceptional mechanical strength and thermal insulation, making it ideal for industrial applications requiring durability. Carbon aerogel features an ultra-low density and an extremely high surface area, providing superior thermal insulation and adsorption capabilities. Both materials excel in energy storage and environmental applications but differ primarily in pore size, mechanical properties, and density.

Table of Comparison

| Property | Carbon Foam | Carbon Aerogel |

|---|---|---|

| Density | 0.2 - 0.5 g/cm3 | 0.003 - 0.1 g/cm3 |

| Porosity | 70% - 90% | 90% - 99.9% |

| Thermal Conductivity | 0.1 - 0.3 W/m*K | 0.02 - 0.05 W/m*K |

| Mechanical Strength | High, rigid structure | Low, fragile structure |

| Electrical Conductivity | Moderate to high | High |

| Typical Applications | Heat exchangers, electrodes, lightweight structural components | Thermal insulation, sensors, energy storage (supercapacitors) |

| Manufacturing Process | Polymer pyrolysis, templating | Sol-gel polymerization, supercritical drying |

Introduction to Carbon Foam and Carbon Aerogel

Carbon foam and carbon aerogel are advanced porous materials used in various high-tech applications due to their exceptional thermal insulation, lightweight structure, and high surface area. Carbon foam typically features an interconnected network of relatively large pores, providing structural strength and efficient heat dissipation, making it ideal for thermal management in electronics and aerospace industries. Carbon aerogel, characterized by its nanoscale pore size and ultra-low density, offers superior insulation properties and high adsorption capacity, making it suitable for energy storage, catalyst support, and environmental cleanup technologies.

Key Properties of Carbon Foam

Carbon foam features a porous, rigid structure with high thermal stability, low density, and excellent electrical conductivity. Its open-cell configuration provides superior mechanical strength and efficient heat dissipation, making it ideal for lightweight structural components and thermal insulation. Compared to carbon aerogel, carbon foam exhibits greater durability and robustness under mechanical stress.

Key Properties of Carbon Aerogel

Carbon aerogel exhibits exceptional properties such as ultra-low density, high porosity exceeding 90%, and a large specific surface area often above 500 m2/g, making it highly efficient for insulation and energy storage applications. Its unique nanostructure provides superior electrical conductivity and thermal resistance compared to carbon foam, enabling enhanced performance in supercapacitors and catalytic supports. The lightweight and mechanical flexibility of carbon aerogel further distinguishes it from denser, more rigid carbon foam materials.

Manufacturing Processes: Carbon Foam vs Carbon Aerogel

Carbon foam is typically manufactured through a polymer pyrolysis process where a polymer precursor is foamed and then carbonized at high temperatures, resulting in a porous structure with relatively larger pore sizes. In contrast, carbon aerogel is synthesized using a sol-gel process followed by supercritical drying and carbonization, producing an ultra-lightweight material with nanoscale porosity. The key manufacturing distinction lies in aerogel's wet gel processing and drying techniques, which enable a more controlled pore size distribution and higher surface area compared to the foam's bulk carbonization approach.

Structural Differences Between Carbon Foam and Carbon Aerogel

Carbon foam features a porous structure with interconnected macropores typically ranging from 100 to 500 micrometers, providing high mechanical strength and thermal stability. In contrast, carbon aerogel consists of a highly porous, nanoporous network with pore sizes below 50 nanometers, resulting in extremely low density and high surface area. The macroporous framework of carbon foam is ideal for structural applications, while the nanoporous carbon aerogel excels in adsorption and insulation due to its ultrafine pore architecture.

Thermal Insulation Capabilities: A Comparative Analysis

Carbon foam exhibits moderate thermal insulation due to its porous structure with interconnected cells that trap air, providing resistance to heat transfer. Carbon aerogel, characterized by its ultra-lightweight and highly porous nanoscale framework, offers superior thermal insulation performance with extremely low thermal conductivity values often below 0.02 W/m*K. Comparative analysis reveals that carbon aerogels outperform carbon foam in insulating applications requiring minimal heat loss, making them ideal for advanced thermal management systems.

Mechanical Strength and Durability Comparison

Carbon foam exhibits superior mechanical strength due to its rigid, porous structure, making it highly resistant to compression and impact forces compared to carbon aerogel. Carbon aerogel, while extremely lightweight and possessing excellent energy absorption, generally has lower mechanical durability and is more prone to structural deformation under stress. The choice between carbon foam and carbon aerogel depends on the application requirements for strength versus weight and resilience over prolonged use.

Applications in Industry and Research

Carbon foam exhibits high thermal insulation and mechanical strength, making it ideal for aerospace components and heat exchangers, where durability and temperature resistance are critical. Carbon aerogel offers exceptional porosity and surface area, enabling advanced applications in energy storage, catalyst supports, and environmental remediation. Research explores carbon foam for structural composites, while carbon aerogel is favored for supercapacitors and sensor technologies due to its enhanced electrochemical properties.

Cost and Scalability Considerations

Carbon foam generally offers a more cost-effective and scalable production process compared to carbon aerogel, mainly due to its simpler manufacturing techniques and availability of raw materials. Carbon aerogels, while providing superior surface area and porosity, involve higher costs associated with complex sol-gel synthesis and supercritical drying methods, limiting large-scale applications. For industries prioritizing budget and mass production, carbon foam remains the preferred choice, whereas carbon aerogel is suited for specialized, high-performance uses despite its scalability challenges.

Future Trends in Carbon Foam and Carbon Aerogel Technology

Carbon foam is expected to advance with enhanced thermal insulation and mechanical strength for aerospace and energy storage applications, leveraging nano-engineered pore structures to improve performance. Carbon aerogel technology is trending towards ultra-lightweight, high-surface-area materials optimized for supercapacitors and environmental cleanup, emphasizing scalable synthesis methods and multifunctionality. Both materials show promise in integrating with smart sensors and flexible electronics, driving innovation in wearable technology and sustainable energy solutions.

Carbon foam vs Carbon aerogel Infographic

materialdif.com

materialdif.com