Carbon coating enhances the surface properties of materials by applying a thin, uniform carbon layer that increases wear resistance and electrical conductivity without altering the bulk material's structure. Carbon doping incorporates carbon atoms directly into the material's lattice, modifying its intrinsic electronic, mechanical, and chemical properties for improved performance at the fundamental level. Both techniques optimize carbon-based PET applications, with coating providing surface protection and doping enabling tailored material characteristics.

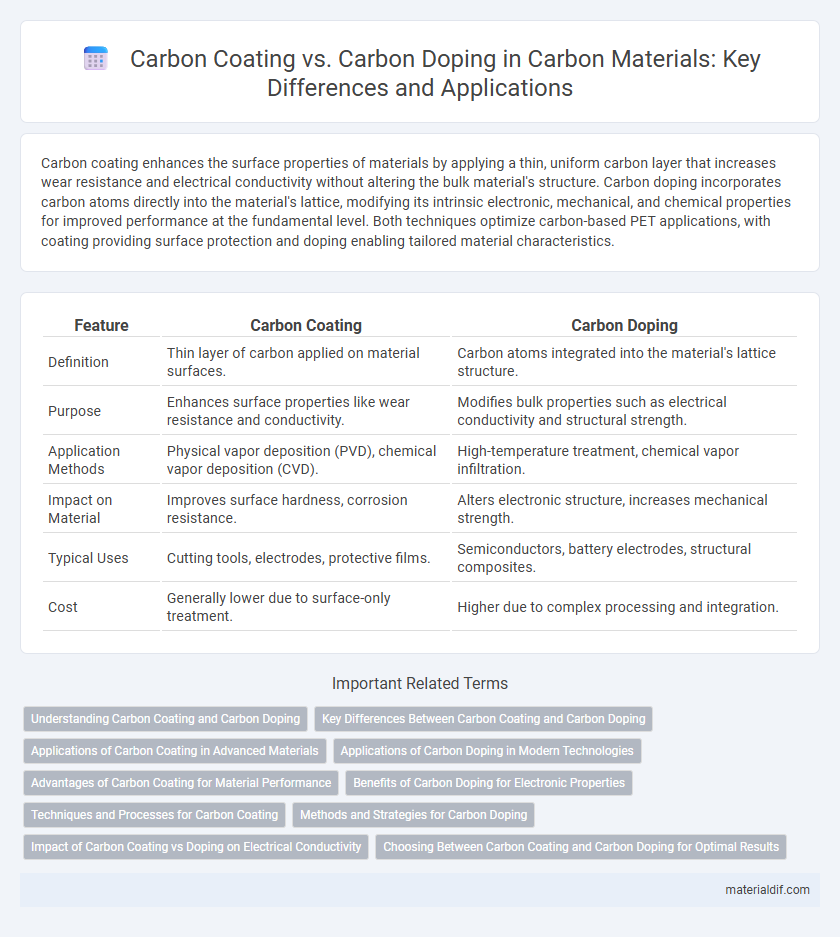

Table of Comparison

| Feature | Carbon Coating | Carbon Doping |

|---|---|---|

| Definition | Thin layer of carbon applied on material surfaces. | Carbon atoms integrated into the material's lattice structure. |

| Purpose | Enhances surface properties like wear resistance and conductivity. | Modifies bulk properties such as electrical conductivity and structural strength. |

| Application Methods | Physical vapor deposition (PVD), chemical vapor deposition (CVD). | High-temperature treatment, chemical vapor infiltration. |

| Impact on Material | Improves surface hardness, corrosion resistance. | Alters electronic structure, increases mechanical strength. |

| Typical Uses | Cutting tools, electrodes, protective films. | Semiconductors, battery electrodes, structural composites. |

| Cost | Generally lower due to surface-only treatment. | Higher due to complex processing and integration. |

Understanding Carbon Coating and Carbon Doping

Carbon coating involves applying a uniform layer of carbon material onto the surface of a substrate to enhance properties such as conductivity, corrosion resistance, and wear resistance. Carbon doping introduces carbon atoms into the lattice structure of a material, altering its electrical and mechanical characteristics by creating defects or changing the band structure. Understanding the fundamental differences between carbon coating and carbon doping is crucial for tailoring the performance of advanced materials in applications like electronics, energy storage, and catalysis.

Key Differences Between Carbon Coating and Carbon Doping

Carbon coating enhances surface properties by applying a thin carbon layer onto materials, improving corrosion resistance and conductivity without altering the bulk composition. Carbon doping involves integrating carbon atoms into the crystal lattice of a material, significantly modifying its electronic, optical, or mechanical properties at the atomic level. Key differences include coating being a surface modification technique, while doping fundamentally changes the material's internal structure and properties.

Applications of Carbon Coating in Advanced Materials

Carbon coating enhances surface properties such as hardness, corrosion resistance, and electrical conductivity, making it essential in cutting tools, biomedical implants, and electronics. This technique improves wear resistance and prolongs component lifespan in aerospace and automotive industries by providing a protective carbon layer. Carbon doping modifies bulk material properties at the atomic level, whereas carbon coating primarily serves as a functional surface modification for advanced material applications.

Applications of Carbon Doping in Modern Technologies

Carbon doping enhances semiconductor performance by introducing carbon atoms into the crystal lattice, improving thermal stability and electrical conductivity in devices like high-power transistors and LEDs. This technique is crucial in advanced electronics, enabling more efficient power management and longer device lifespans compared to traditional carbon coating methods. Carbon doping also plays a vital role in quantum computing and spintronics by modulating material properties at the atomic level for superior functionality.

Advantages of Carbon Coating for Material Performance

Carbon coating enhances material performance by creating a protective barrier that improves corrosion resistance and reduces wear, extending the lifespan of components. It provides uniform surface coverage, which optimizes thermal stability and electrical conductivity without altering the bulk properties of the substrate. This method also offers superior control over thickness and composition compared to carbon doping, making it ideal for applications demanding precise surface enhancement.

Benefits of Carbon Doping for Electronic Properties

Carbon doping enhances electronic properties by introducing controlled impurities that improve conductivity and charge carrier mobility in semiconductors. Unlike carbon coating, which primarily provides surface protection, carbon doping modifies the internal crystal structure, resulting in increased efficiency and stability of electronic devices. This technique is widely used in applications such as transistors, sensors, and photovoltaic cells to optimize performance and durability.

Techniques and Processes for Carbon Coating

Carbon coating involves applying a thin layer of carbon onto a substrate through techniques such as chemical vapor deposition (CVD), physical vapor deposition (PVD), and spray pyrolysis, which enhance surface properties like wear resistance and conductivity. Carbon doping incorporates carbon atoms directly into the crystal lattice of materials using methods like ion implantation or plasma-enhanced CVD to alter electronic and mechanical characteristics. Carbon coating processes emphasize controlled deposition parameters including temperature, gas composition, and pressure to achieve uniformity and adhesion critical for performance in applications like batteries and catalysts.

Methods and Strategies for Carbon Doping

Carbon doping involves the intentional introduction of carbon atoms into a material's lattice structure using methods such as chemical vapor deposition (CVD), ion implantation, or solid-state diffusion, enhancing electrical conductivity and mechanical properties. In contrast, carbon coating typically applies a carbon layer onto the surface through techniques like sputtering or pyrolysis, primarily improving surface hardness and corrosion resistance without altering the bulk material properties. Strategies for effective carbon doping focus on controlling doping concentration, uniformity, and depth profile to optimize material performance in applications like semiconductors and battery electrodes.

Impact of Carbon Coating vs Doping on Electrical Conductivity

Carbon coating enhances electrical conductivity by creating a continuous conductive layer on the surface of materials, improving electron transport pathways and reducing resistance. In contrast, carbon doping introduces carbon atoms into the material's lattice, altering its electronic structure and carrier concentration, which can either increase or decrease conductivity depending on the doping level and material type. The impact of carbon coating is typically more pronounced in surface-dominated conduction, while doping effects are critical in tailoring bulk electronic properties for semiconductors or battery electrodes.

Choosing Between Carbon Coating and Carbon Doping for Optimal Results

Carbon coating enhances surface properties by applying a thin carbon layer, improving hardness, corrosion resistance, and conductivity, ideal for protecting materials from external damage. Carbon doping integrates carbon atoms into the crystal lattice, modifying electrical, optical, and mechanical properties at the atomic level, crucial for semiconductor and advanced material applications. Selecting between carbon coating and carbon doping depends on whether surface protection or intrinsic material modification aligns better with the desired performance outcomes.

Carbon coating vs Carbon doping Infographic

materialdif.com

materialdif.com