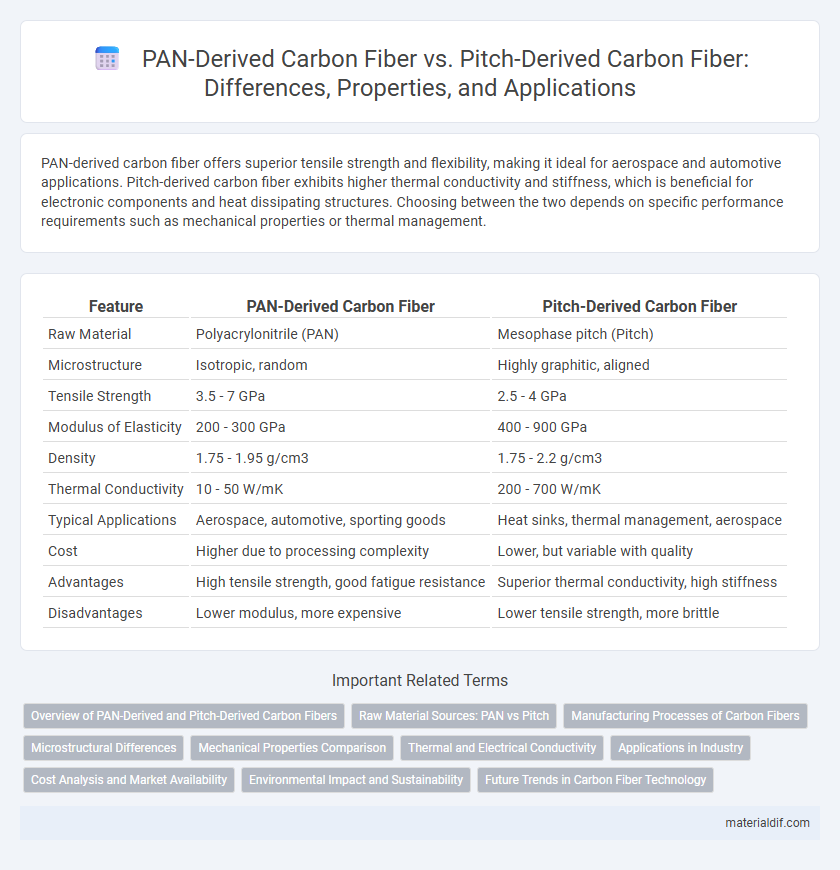

PAN-derived carbon fiber offers superior tensile strength and flexibility, making it ideal for aerospace and automotive applications. Pitch-derived carbon fiber exhibits higher thermal conductivity and stiffness, which is beneficial for electronic components and heat dissipating structures. Choosing between the two depends on specific performance requirements such as mechanical properties or thermal management.

Table of Comparison

| Feature | PAN-Derived Carbon Fiber | Pitch-Derived Carbon Fiber |

|---|---|---|

| Raw Material | Polyacrylonitrile (PAN) | Mesophase pitch (Pitch) |

| Microstructure | Isotropic, random | Highly graphitic, aligned |

| Tensile Strength | 3.5 - 7 GPa | 2.5 - 4 GPa |

| Modulus of Elasticity | 200 - 300 GPa | 400 - 900 GPa |

| Density | 1.75 - 1.95 g/cm3 | 1.75 - 2.2 g/cm3 |

| Thermal Conductivity | 10 - 50 W/mK | 200 - 700 W/mK |

| Typical Applications | Aerospace, automotive, sporting goods | Heat sinks, thermal management, aerospace |

| Cost | Higher due to processing complexity | Lower, but variable with quality |

| Advantages | High tensile strength, good fatigue resistance | Superior thermal conductivity, high stiffness |

| Disadvantages | Lower modulus, more expensive | Lower tensile strength, more brittle |

Overview of PAN-Derived and Pitch-Derived Carbon Fibers

PAN-derived carbon fibers are produced by stabilizing and carbonizing polyacrylonitrile precursors, resulting in fibers characterized by high tensile strength and excellent modulus, commonly used in aerospace and automotive applications. Pitch-derived carbon fibers are obtained through the carbonization of petroleum or coal tar pitch, offering superior thermal conductivity and stiffness, making them ideal for high-temperature and thermal management uses. Both types differ significantly in microstructure and mechanical properties, influencing their selection based on specific industrial requirements.

Raw Material Sources: PAN vs Pitch

PAN-derived carbon fibers originate from polyacrylonitrile, a synthetic polymer made through controlled polymerization of acrylonitrile monomers, offering high purity and consistent quality. In contrast, pitch-derived carbon fibers are produced from petroleum or coal tar pitch, which consists of complex aromatic hydrocarbons, resulting in raw materials that vary significantly in molecular structure and composition. The choice between PAN and pitch raw materials impacts fiber properties due to differences in precursor molecular weight, thermal stability, and carbon yield during the carbonization process.

Manufacturing Processes of Carbon Fibers

PAN-derived carbon fibers are produced through the stabilization, carbonization, and graphitization of polyacrylonitrile precursors involving oxidative stabilization at 200-300degC, followed by high-temperature carbonization above 1000degC. Pitch-derived carbon fibers originate from mesophase pitch, requiring melt spinning, stabilization, and carbonization, with processing temperatures often exceeding 1300degC to achieve graphitic structures. The manufacturing process of PAN fibers offers higher tensile strength due to better molecular alignment, while pitch fibers provide higher modulus attributed to their graphitic crystal structure formed during high-temperature treatment.

Microstructural Differences

PAN-derived carbon fibers exhibit a turbostratic microstructure characterized by disordered graphitic layers with randomly oriented graphene planes, resulting in higher tensile strength and better fiber toughness. Pitch-derived carbon fibers possess a highly ordered graphitic microstructure with well-aligned and stacked graphene layers, contributing to superior modulus and electrical conductivity. The microstructural differences influence their mechanical properties and suitability for applications requiring specific strength-to-weight ratios or electrical performance.

Mechanical Properties Comparison

PAN-derived carbon fibers offer higher tensile strength typically ranging from 3.5 to 7 GPa, making them ideal for aerospace and automotive applications requiring durability and impact resistance. Pitch-derived carbon fibers exhibit superior modulus values, often exceeding 500 GPa, providing exceptional stiffness suitable for high-performance structural components. While PAN fibers excel in strength and fatigue resistance, pitch fibers are favored in applications demanding rigidity and thermal stability.

Thermal and Electrical Conductivity

PAN-derived carbon fibers typically exhibit higher tensile strength but lower thermal and electrical conductivity compared to pitch-derived carbon fibers. Pitch-derived carbon fibers offer superior thermal conductivity, often exceeding 400 W/m*K, making them ideal for heat dissipation applications. Electrical conductivity in pitch-derived fibers also tends to be significantly higher due to their more graphitic microstructure, enhancing their performance in electronic and conductive materials.

Applications in Industry

PAN-derived carbon fiber dominates aerospace and automotive industries due to its high tensile strength and lightweight properties, making it ideal for structural components and sporting equipment. Pitch-derived carbon fiber, with superior thermal conductivity and modulus, is preferred in electronic devices, heat exchangers, and nuclear reactors where heat management and stability are critical. Both fibers contribute significantly to industrial advancements, with PAN fibers excelling in mechanical applications and pitch fibers optimizing thermal performance.

Cost Analysis and Market Availability

PAN-derived carbon fiber dominates the market due to its balanced cost structure and widespread production infrastructure, making it more accessible and affordable for industries like aerospace and automotive. Pitch-derived carbon fibers tend to have higher production costs and limited commercial availability, as their niche applications require specialized processes and higher temperature treatments. Market analysis shows PAN-based fibers hold over 90% market share, driven by cost efficiency and scalability compared to the more expensive, less available pitch-based alternatives.

Environmental Impact and Sustainability

PAN-derived carbon fiber generates higher greenhouse gas emissions during production compared to pitch-derived carbon fiber, which benefits from lower energy requirements. Pitch-derived carbon fiber offers improved recyclability and reduced environmental footprint due to its inherently lower processing temperatures and use of aromatic hydrocarbons. Sustainable development in carbon fiber manufacturing increasingly favors pitch-derived alternatives for minimizing carbon emissions and enhancing lifecycle sustainability.

Future Trends in Carbon Fiber Technology

PAN-derived carbon fiber continues to dominate the market due to its superior tensile strength and versatility in aerospace and automotive industries. Pitch-derived carbon fiber, known for its exceptional thermal conductivity and high modulus, is gaining attention for specialized applications in electronics and heat dissipation systems. Future trends indicate a growing integration of hybrid carbon fibers combining PAN and pitch precursors to optimize mechanical properties and thermal performance for advanced composite materials.

PAN-derived carbon fiber vs Pitch-derived carbon fiber Infographic

materialdif.com

materialdif.com