Carbon fiber consists of tightly woven strands of carbon atoms providing exceptional strength and lightweight properties. Carbon composite combines carbon fiber with a resin matrix to enhance durability and flexibility, making it ideal for complex shapes and high-performance applications. While carbon fiber offers superior tensile strength, carbon composite delivers improved structural integrity and resistance to impact.

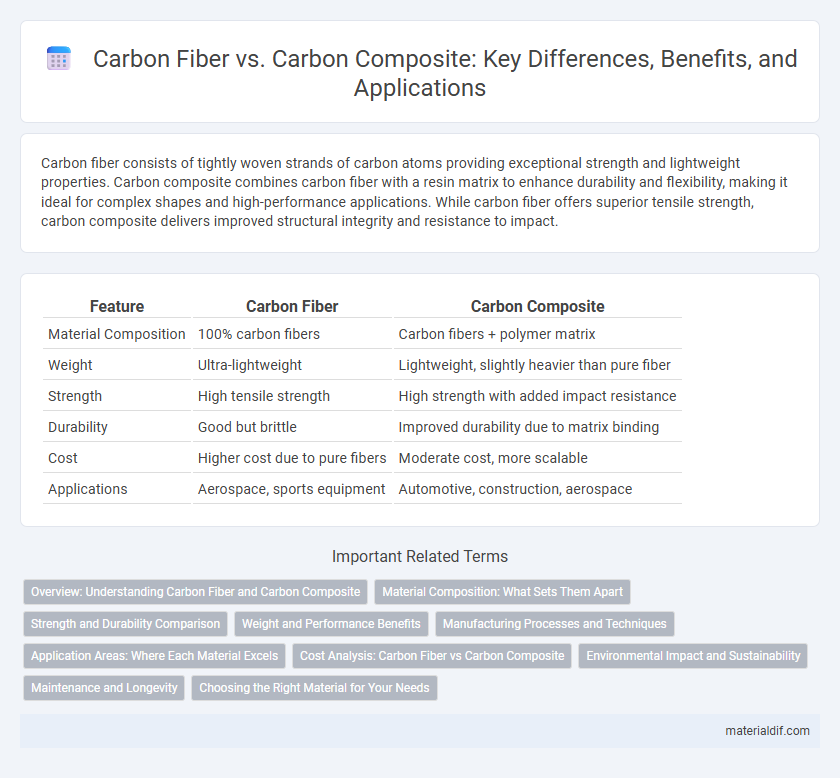

Table of Comparison

| Feature | Carbon Fiber | Carbon Composite |

|---|---|---|

| Material Composition | 100% carbon fibers | Carbon fibers + polymer matrix |

| Weight | Ultra-lightweight | Lightweight, slightly heavier than pure fiber |

| Strength | High tensile strength | High strength with added impact resistance |

| Durability | Good but brittle | Improved durability due to matrix binding |

| Cost | Higher cost due to pure fibers | Moderate cost, more scalable |

| Applications | Aerospace, sports equipment | Automotive, construction, aerospace |

Overview: Understanding Carbon Fiber and Carbon Composite

Carbon fiber consists of thin strands of carbon atoms tightly bonded in a crystalline formation, offering exceptional strength and lightweight properties. Carbon composite materials integrate carbon fibers with a resin matrix, enhancing durability and structural integrity for applications in aerospace, automotive, and sports equipment. The combination of carbon fiber and resin in composites maximizes performance by providing both rigidity and resistance to impact.

Material Composition: What Sets Them Apart

Carbon fiber consists of thin, strong crystalline filaments of carbon tightly woven into a fabric, while carbon composites combine these fibers with a polymer resin matrix to form a solid material. The key differentiation lies in carbon fiber's pure fiber form, offering high tensile strength and stiffness, whereas carbon composites leverage the resin to provide shape, structural bonding, and enhanced durability. This material composition makes carbon composites preferred for complex structural applications that require both strength and lightweight performance.

Strength and Durability Comparison

Carbon fiber exhibits exceptional tensile strength, often exceeding 3,500 MPa, while carbon composites integrate carbon fibers with resin matrices that enhance overall structural integrity and impact resistance. The durability of carbon composites surpasses pure carbon fiber by offering improved resistance to fatigue, environmental degradation, and mechanical wear. This combination results in materials optimized for high-performance applications where both strength and long-term durability are critical.

Weight and Performance Benefits

Carbon fiber offers exceptional strength-to-weight ratio, making it significantly lighter than traditional materials while maintaining high tensile strength. Carbon composites, which combine carbon fibers with resin matrices, enhance performance by providing improved stiffness, durability, and resistance to fatigue, essential for aerospace and automotive applications. The integration of carbon fibers in composite materials results in optimized weight reduction without compromising structural integrity, leading to superior efficiency and performance benefits.

Manufacturing Processes and Techniques

Carbon fiber manufacturing involves weaving thin strands of carbon filaments into fabric sheets, which are then combined under heat and pressure with epoxy resin to create lightweight, high-strength materials. Carbon composites refer to the finished products made by layering carbon fiber fabrics with resin matrices through processes such as lay-up, resin transfer molding (RTM), or autoclave curing, resulting in tailored mechanical properties. Advanced techniques like vacuum bagging improve fiber-resin consolidation and reduce void content, enhancing the structural performance of carbon composite parts.

Application Areas: Where Each Material Excels

Carbon fiber excels in aerospace, automotive, and sports equipment due to its exceptional strength-to-weight ratio and stiffness, making it ideal for high-performance applications. Carbon composites, which combine carbon fibers with various resins, provide enhanced durability and impact resistance, making them suitable for automotive body panels, wind turbine blades, and construction materials. The choice between carbon fiber and carbon composites depends on specific application requirements, such as weight reduction, structural integrity, and environmental resistance.

Cost Analysis: Carbon Fiber vs Carbon Composite

Carbon fiber typically incurs higher material costs due to its pure fiber content and manufacturing processes, while carbon composites combine carbon fiber with resin matrices, reducing overall expenses by optimizing material use. The cost-effectiveness of carbon composites makes them favorable in large-scale applications where performance-to-price ratio is critical, despite slightly lower strength-to-weight ratios compared to pure carbon fiber. Evaluating long-term durability and repair costs, carbon composites often offer better value in industries such as automotive and aerospace, balancing initial investment with functional efficiency.

Environmental Impact and Sustainability

Carbon fiber and carbon composites differ in environmental impact, with carbon fiber production typically consuming high energy and generating significant carbon emissions due to its energy-intensive manufacturing process. Carbon composites, which combine carbon fiber with resin matrices, present challenges in recycling and disposal, leading to concerns about long-term sustainability and environmental burden. Efforts to develop bio-based resins and improve recycling technologies are critical to enhancing the eco-friendliness and circularity of carbon composite materials.

Maintenance and Longevity

Carbon fiber offers superior tensile strength and rigidity, but it can be more susceptible to surface damage and requires specialized repairs. Carbon composites, combining carbon fiber with resin matrices, provide enhanced durability and resistance to environmental factors, reducing maintenance frequency. Longevity of carbon composites typically exceeds that of pure carbon fiber due to better impact absorption and protection against corrosion.

Choosing the Right Material for Your Needs

Carbon fiber offers exceptional tensile strength and lightweight properties, ideal for applications requiring maximum stiffness and durability, such as aerospace and sports equipment. Carbon composite materials combine carbon fibers with resin matrices, providing enhanced flexibility, impact resistance, and design versatility for automotive and structural components. Selecting between carbon fiber and carbon composite depends on specific performance needs, cost considerations, and environmental exposure factors.

Carbon Fiber vs Carbon Composite Infographic

materialdif.com

materialdif.com