Carbon black and carbon nanofiber differ significantly in structure and application; carbon black consists of fine particles primarily used as a reinforcing filler in rubber and pigment in inks and coatings, while carbon nanofibers have a fibrous morphology with higher aspect ratios, offering superior mechanical strength and electrical conductivity. Carbon nanofibers enhance composite materials by improving stiffness and durability, making them ideal for aerospace and automotive industries. The choice between carbon black and carbon nanofiber depends on the desired performance characteristics and cost considerations in industrial applications.

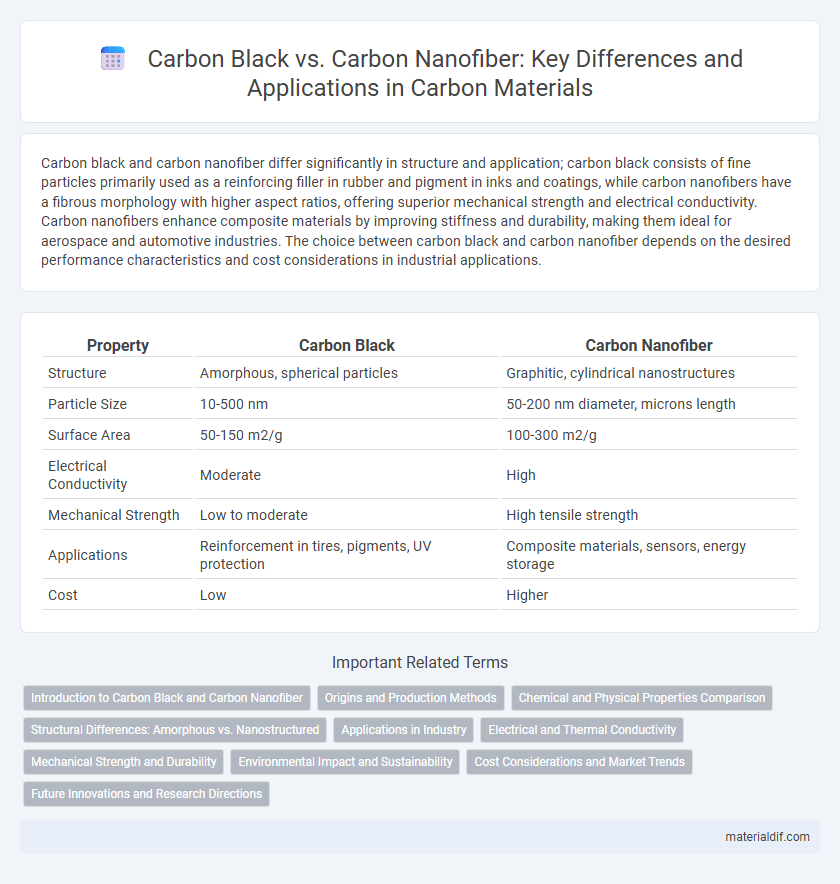

Table of Comparison

| Property | Carbon Black | Carbon Nanofiber |

|---|---|---|

| Structure | Amorphous, spherical particles | Graphitic, cylindrical nanostructures |

| Particle Size | 10-500 nm | 50-200 nm diameter, microns length |

| Surface Area | 50-150 m2/g | 100-300 m2/g |

| Electrical Conductivity | Moderate | High |

| Mechanical Strength | Low to moderate | High tensile strength |

| Applications | Reinforcement in tires, pigments, UV protection | Composite materials, sensors, energy storage |

| Cost | Low | Higher |

Introduction to Carbon Black and Carbon Nanofiber

Carbon black consists of fine carbon particles primarily used as a reinforcing agent in rubber and as a pigment in inks and coatings, notable for its high surface area and excellent conductivity. Carbon nanofibers are cylindrical nanostructures with superior mechanical strength, electrical conductivity, and thermal stability, applied in advanced composites and electronics. Both materials derive from carbon but differ significantly in morphology, scale, and application performance, influencing their industrial utility.

Origins and Production Methods

Carbon black is primarily produced through the incomplete combustion of heavy petroleum products such as coal tar and ethylene cracking tar, resulting in fine particles used mainly as a reinforcing filler in rubber and pigments. Carbon nanofibers, however, are synthesized via catalytic chemical vapor deposition (CVD), where hydrocarbons decompose on metal catalysts like nickel or cobalt to form nanoscale fibrous structures with high aspect ratios. The distinct production methods reflect their different physical forms and applications, with carbon black emerging from bulk pyrolysis processes and carbon nanofibers requiring precise catalyst-driven growth techniques.

Chemical and Physical Properties Comparison

Carbon black exhibits a high surface area with amorphous, quasi-spherical particles predominantly composed of elemental carbon, resulting in excellent conductivity and UV protection, whereas carbon nanofibers possess a graphitic, cylindrical morphology with high tensile strength and electrical conductivity due to their ordered crystalline structure. Chemically, carbon black contains various functional groups and impurities influencing reactivity, while carbon nanofibers demonstrate greater chemical stability and resistance to oxidation. Physically, carbon black particles aggregate into larger clusters, impacting dispersion and mechanical reinforcement differently compared to the high aspect ratio and superior mechanical performance of carbon nanofibers in composite materials.

Structural Differences: Amorphous vs. Nanostructured

Carbon black exhibits an amorphous structure characterized by disordered, spherical particles that aggregate to form a complex network. In contrast, carbon nanofibers possess a nanostructured morphology with graphitic layers aligned along the fiber axis, resulting in enhanced mechanical strength and electrical conductivity. These fundamental structural differences directly influence their respective performance in applications such as reinforcement materials and conductive composites.

Applications in Industry

Carbon black is extensively used in the tire and rubber industry due to its excellent reinforcing properties and cost-effectiveness, enhancing durability and wear resistance. Carbon nanofibers find applications in advanced composites, electronics, and energy storage devices, where their superior mechanical strength, electrical conductivity, and lightweight nature improve performance and efficiency. Industrial sectors such as aerospace, automotive, and electronics leverage carbon nanofiber technology for innovative material solutions, while carbon black remains dominant in large-scale manufacturing and pigmentation processes.

Electrical and Thermal Conductivity

Carbon black exhibits moderate electrical conductivity due to its amorphous structure and high surface area, making it suitable for enhancing electrical properties in polymers and batteries. In contrast, carbon nanofibers possess superior electrical conductivity resulting from their graphitic crystalline structure, facilitating efficient electron transport pathways. Thermal conductivity is also significantly higher in carbon nanofibers, enabling effective heat dissipation in advanced composite materials, whereas carbon black provides only limited thermal conductivity improvements.

Mechanical Strength and Durability

Carbon nanofiber exhibits significantly higher mechanical strength and durability compared to carbon black due to its unique cylindrical nanostructure and larger aspect ratio, which enable better stress distribution and resistance to fracture. Carbon black, consisting of aggregated spherical particles, provides good reinforcement in polymers but lacks the superior tensile strength and fatigue resistance characteristic of carbon nanofibers. Enhanced durability of carbon nanofibers stems from their graphitic crystallinity and alignment, resulting in improved load transfer and long-term performance in composite materials.

Environmental Impact and Sustainability

Carbon black exhibits higher environmental concerns due to its energy-intensive production and significant particulate emissions, contributing to air pollution and health risks. In contrast, carbon nanofibers, despite being energy-demanding to manufacture, offer enhanced sustainability through their potential for lightweight composites, improving fuel efficiency and reducing carbon footprints in automotive and aerospace industries. The durability and recyclability of carbon nanofiber-based materials also position them as a more environmentally sustainable choice over traditional carbon black in advanced applications.

Cost Considerations and Market Trends

Carbon black exhibits lower production costs compared to carbon nanofibers, making it more accessible for large-scale applications in rubber reinforcement and pigment industries. Carbon nanofibers command higher prices due to complex manufacturing processes, limiting their current market penetration primarily to advanced composites and electronic markets. Market trends indicate a growing demand for carbon nanofibers driven by innovation in aerospace and automotive sectors, whereas carbon black maintains steady demand due to its cost-effectiveness and established applications.

Future Innovations and Research Directions

Carbon black, a traditional reinforcing filler in tires and plastics, faces limitations in mechanical performance improvements compared to carbon nanofibers, which exhibit superior tensile strength, electrical conductivity, and thermal stability. Future innovations are focusing on hybrid composites combining carbon black with carbon nanofibers to achieve enhanced multifunctionality, including improved wear resistance and sensor capabilities. Research directions prioritize scalable synthesis methods, eco-friendly production, and integration of carbon nanofibers in energy storage, flexible electronics, and lightweight structural materials.

Carbon black vs Carbon nanofiber Infographic

materialdif.com

materialdif.com