Isotropic graphite exhibits uniform properties in all directions due to its fine, randomly oriented grain structure, making it ideal for applications requiring consistent mechanical strength and thermal conductivity. Extruded graphite, formed through a directional extrusion process, has oriented grains that provide higher strength and thermal conductivity along the extrusion axis but lower performance perpendicular to it. Selection between isotropic and extruded graphite depends on the specific requirements for anisotropy, mechanical strength, and thermal management in industrial applications.

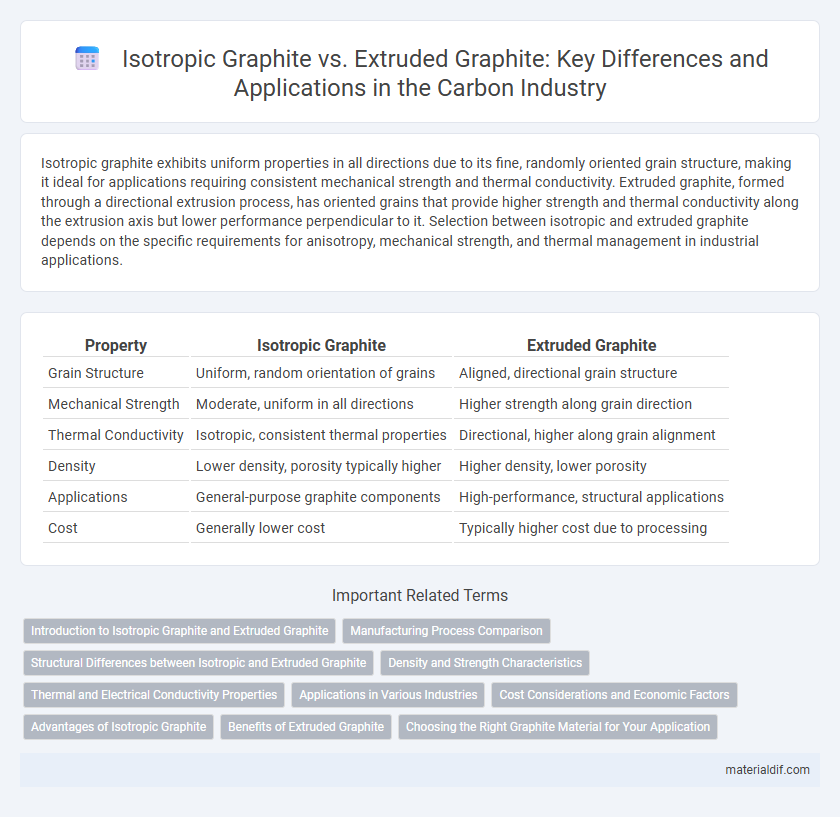

Table of Comparison

| Property | Isotropic Graphite | Extruded Graphite |

|---|---|---|

| Grain Structure | Uniform, random orientation of grains | Aligned, directional grain structure |

| Mechanical Strength | Moderate, uniform in all directions | Higher strength along grain direction |

| Thermal Conductivity | Isotropic, consistent thermal properties | Directional, higher along grain alignment |

| Density | Lower density, porosity typically higher | Higher density, lower porosity |

| Applications | General-purpose graphite components | High-performance, structural applications |

| Cost | Generally lower cost | Typically higher cost due to processing |

Introduction to Isotropic Graphite and Extruded Graphite

Isotropic graphite exhibits uniform properties in all directions due to its fine, evenly distributed grain structure, making it ideal for applications requiring consistent thermal and electrical conductivity. Extruded graphite is produced by forcing graphite paste through a die, resulting in a material with anisotropic properties, stronger in one direction, and is often used in manufacturing high-strength components. Both forms serve critical roles in industries such as aerospace, nuclear, and electronics, where tailored mechanical and thermal characteristics are essential.

Manufacturing Process Comparison

Isotropic graphite is manufactured through a molding process that involves mixing coke and pitch binder, followed by baking and graphitization to achieve uniform properties in all directions. Extruded graphite is produced by forcing a graphitizable mixture through a die, resulting in a directional grain structure with improved mechanical strength along the extrusion axis. The manufacturing process of isotropic graphite allows for consistent isotropy and machinability, whereas extruded graphite offers enhanced strength and thermal conductivity due to its aligned grain structure.

Structural Differences between Isotropic and Extruded Graphite

Isotropic graphite exhibits uniform microstructure with randomly oriented graphite grains, resulting in consistent mechanical properties in all directions. Extruded graphite features aligned graphite particles due to the extrusion process, enhancing strength and thermal conductivity along the extrusion axis while reducing properties in transverse directions. These structural differences influence material selection for applications requiring specific directional performance characteristics.

Density and Strength Characteristics

Isotropic graphite exhibits uniform density and strength properties in all directions due to its fine-grained, randomly oriented microstructure, which typically results in densities ranging from 1.6 to 1.8 g/cm3 and compressive strengths between 100 to 250 MPa. Extruded graphite has anisotropic density and strength with higher mechanical strength along the extrusion direction, densities generally around 1.7 to 1.9 g/cm3, and compressive strengths often exceeding 200 MPa in the primary axis. The choice between isotropic and extruded graphite depends heavily on the specific application requiring balanced strength or directional mechanical performance.

Thermal and Electrical Conductivity Properties

Isotropic graphite exhibits uniform thermal and electrical conductivity in all directions due to its randomly oriented graphite grains, ideal for applications requiring consistent performance. Extruded graphite, with aligned graphite grains, shows higher thermal and electrical conductivity along the extrusion direction, offering enhanced directional conductivity but reduced isotropy. The choice between isotropic and extruded graphite depends on the specific thermal management or electrical conduction requirements in high-temperature or electronic environments.

Applications in Various Industries

Isotropic graphite offers uniform properties in all directions, making it ideal for precision components in aerospace and semiconductor industries where consistent thermal and electrical conductivity is critical. Extruded graphite, characterized by its anisotropic structure, is preferred in automotive and heavy machinery applications due to its strength and machinability for complex shapes like seals and bearings. Both types are crucial in nuclear reactors, but isotropic graphite's superior structural integrity supports high-stress environments better than extruded variants.

Cost Considerations and Economic Factors

Isotropic graphite typically incurs higher manufacturing costs due to its uniform grain structure achieved through costly molding and baking processes, making it economically viable for applications demanding high mechanical strength and thermal shock resistance. Extruded graphite, produced by extruding natural coke and pitch, offers lower production costs and faster fabrication, appealing to industries that prioritize budget and efficiency over isotropic properties. Cost considerations often drive material selection, with extruded graphite preferred for large-scale, cost-sensitive projects, while isotropic graphite is reserved for specialized uses where performance justifies its premium price.

Advantages of Isotropic Graphite

Isotropic graphite offers superior uniformity in thermal and electrical conductivity due to its consistent structure, making it ideal for applications requiring even heat distribution and minimal anisotropy. It exhibits enhanced mechanical strength and resistance to stress-induced cracking compared to extruded graphite, increasing durability in high-temperature environments. Its fine grain structure allows for precise machining and improved performance in semiconductor manufacturing and aerospace industries.

Benefits of Extruded Graphite

Extruded graphite offers superior mechanical strength and improved thermal conductivity compared to isotropic graphite, making it ideal for applications requiring high durability and efficient heat dissipation. Its anisotropic structure allows for precise machining and consistent performance under thermal cycling, enhancing reliability in industrial components. Enhanced purity and alignment in extruded graphite contribute to its resistance against oxidation and chemical attack, extending the lifespan of critical parts in harsh environments.

Choosing the Right Graphite Material for Your Application

Isotropic graphite offers uniform properties and high thermal stability, making it ideal for applications requiring consistent mechanical strength and thermal conductivity in all directions. Extruded graphite features a directional grain structure that provides superior strength and machinability along the grain, suitable for complex shapes and high-stress environments. Selecting the right graphite material depends on specific application demands such as thermal conductivity, mechanical strength, and machining requirements.

Isotropic graphite vs Extruded graphite Infographic

materialdif.com

materialdif.com