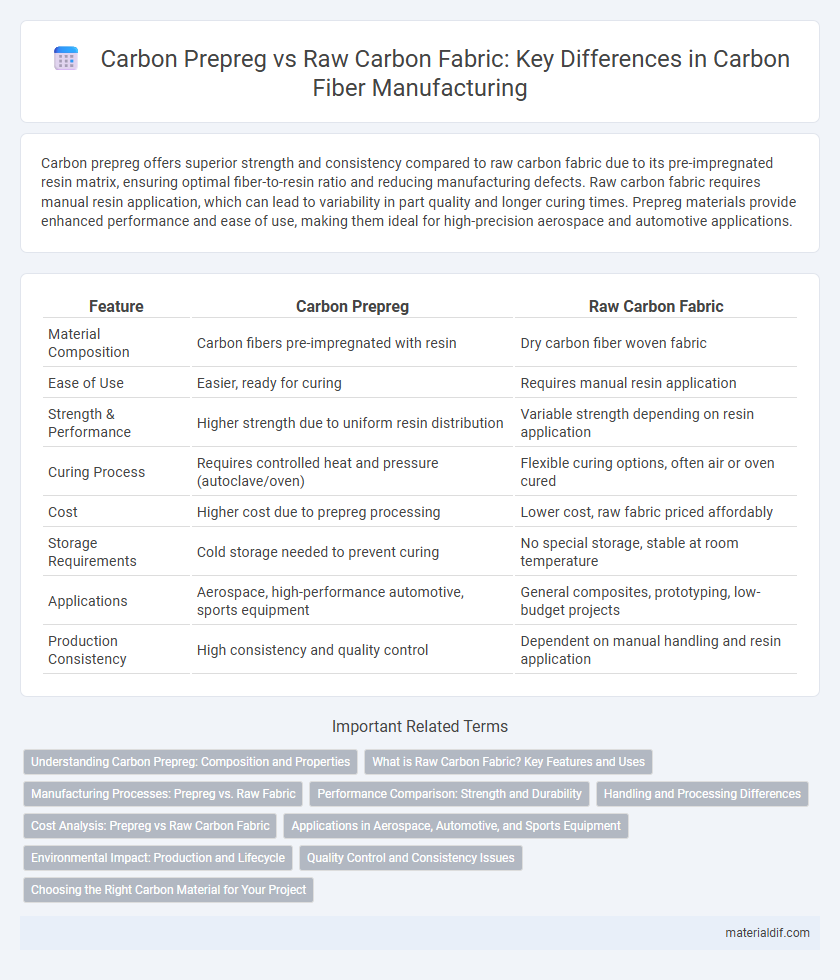

Carbon prepreg offers superior strength and consistency compared to raw carbon fabric due to its pre-impregnated resin matrix, ensuring optimal fiber-to-resin ratio and reducing manufacturing defects. Raw carbon fabric requires manual resin application, which can lead to variability in part quality and longer curing times. Prepreg materials provide enhanced performance and ease of use, making them ideal for high-precision aerospace and automotive applications.

Table of Comparison

| Feature | Carbon Prepreg | Raw Carbon Fabric |

|---|---|---|

| Material Composition | Carbon fibers pre-impregnated with resin | Dry carbon fiber woven fabric |

| Ease of Use | Easier, ready for curing | Requires manual resin application |

| Strength & Performance | Higher strength due to uniform resin distribution | Variable strength depending on resin application |

| Curing Process | Requires controlled heat and pressure (autoclave/oven) | Flexible curing options, often air or oven cured |

| Cost | Higher cost due to prepreg processing | Lower cost, raw fabric priced affordably |

| Storage Requirements | Cold storage needed to prevent curing | No special storage, stable at room temperature |

| Applications | Aerospace, high-performance automotive, sports equipment | General composites, prototyping, low-budget projects |

| Production Consistency | High consistency and quality control | Dependent on manual handling and resin application |

Understanding Carbon Prepreg: Composition and Properties

Carbon prepreg consists of carbon fibers pre-impregnated with a precisely measured resin matrix, typically epoxy, ensuring consistent fiber-to-resin ratio and enhanced mechanical properties. This material offers superior strength, stiffness, and reduced weight compared to raw carbon fabric, which requires manual resin application and curing. The controlled resin content in carbon prepreg results in improved layup quality, reduced voids, and enhanced thermal stability, making it ideal for advanced aerospace, automotive, and sporting goods applications.

What is Raw Carbon Fabric? Key Features and Uses

Raw carbon fabric consists of unprocessed woven carbon fibers, providing a lightweight yet strong base material essential in composites manufacturing. Its key features include high tensile strength, excellent stiffness, and corrosion resistance, making it ideal for aerospace, automotive, and sporting goods applications. Unlike carbon prepreg, raw carbon fabric requires external resin application during layup, offering flexibility in customized composite production.

Manufacturing Processes: Prepreg vs. Raw Fabric

Carbon prepreg undergoes an advanced manufacturing process where carbon fibers are pre-impregnated with a precise resin matrix, ensuring consistent fiber-to-resin ratios and superior structural integrity during curing. Raw carbon fabric requires manual resin application during layup, which can introduce variability in resin distribution and may affect the final composite quality. The controlled resin content in prepregs reduces waste and curing time, making them preferable for high-performance aerospace and automotive components.

Performance Comparison: Strength and Durability

Carbon prepreg offers superior strength and durability compared to raw carbon fabric due to its pre-impregnated resin system that ensures uniform fiber distribution and optimal curing. The controlled resin content in carbon prepreg enhances structural integrity, reducing voids and increasing resistance to fatigue and impact. Raw carbon fabric, while flexible and cost-effective, often results in variable mechanical properties and weaker interlaminar bonding, leading to lower overall performance in high-stress applications.

Handling and Processing Differences

Carbon prepreg materials feature resin-impregnated fibers that provide better tack and shape retention, simplifying layup and reducing handling time compared to raw carbon fabric. Raw carbon fabric requires separate resin application during processing, which may result in more handling complexity and inconsistent resin distribution. Prepregs demand careful storage at low temperatures to prevent premature curing, whereas raw carbon fabric offers more flexibility in storage and preparation timing.

Cost Analysis: Prepreg vs Raw Carbon Fabric

Carbon prepreg offers superior consistency and performance but comes at a higher cost due to specialized resin systems and controlled curing processes, often exceeding raw carbon fabric prices by 30-50%. Raw carbon fabric provides a more economical option with flexible resin choices, leading to lower upfront material expenses but potentially increased labor and processing times. Evaluating overall cost-effectiveness requires balancing initial material costs against performance requirements and manufacturing efficiencies.

Applications in Aerospace, Automotive, and Sports Equipment

Carbon prepreg offers enhanced mechanical properties and consistent fiber-to-resin ratios, making it ideal for aerospace components requiring high strength and lightweight, such as aircraft fuselages and wings. Raw carbon fabric provides flexibility in manufacturing processes, preferred in automotive applications for custom body panels and structural parts where cost-efficiency and design adaptability are crucial. In sports equipment, carbon prepreg enables precision molding for high-performance gear like bicycles and tennis rackets, while raw carbon fabric is often utilized for prototyping and less complex designs.

Environmental Impact: Production and Lifecycle

Carbon prepreg materials typically have a higher environmental impact during production due to the energy-intensive processes and chemical resins involved, resulting in increased carbon emissions. Raw carbon fabric production is generally less resource-intensive, allowing for lower initial environmental footprint and easier recycling at the end of its lifecycle. Lifecycle assessments reveal that raw carbon fabric offers improved sustainability potential through reduced waste and enhanced opportunities for material recovery.

Quality Control and Consistency Issues

Carbon prepreg offers superior quality control and consistency compared to raw carbon fabric due to its pre-impregnated resin system, ensuring uniform resin distribution and reduced variability in fiber alignment. Raw carbon fabric requires manual resin application, increasing the risk of inconsistencies such as resin pooling or dry spots that can compromise structural integrity. Advanced manufacturing processes for carbon prepreg enable tighter tolerances and higher repeatability, essential for aerospace and high-performance automotive applications.

Choosing the Right Carbon Material for Your Project

Carbon prepreg offers enhanced strength and uniform resin distribution due to its pre-impregnated fibers with epoxy resin, making it ideal for high-performance aerospace and automotive applications requiring precise control over material properties. Raw carbon fabric provides greater flexibility and cost-efficiency for projects where customization of resin content and manual lay-up techniques are preferred, often used in prototyping or low-volume production. Selecting the right carbon material depends on factors like mechanical performance demands, budget constraints, and fabrication methods, ensuring optimal composite strength, weight reduction, and durability for the specific project requirements.

Carbon Prepreg vs Raw Carbon Fabric Infographic

materialdif.com

materialdif.com