Carbon reinforcement enhances material strength and stiffness by integrating continuous carbon fibers into composites, resulting in superior mechanical performance and durability. In contrast, carbon additives are fine particulate carbon materials mixed into matrices to improve conductivity, thermal stability, or wear resistance without significantly altering the structural framework. Choosing between carbon reinforcement and carbon additive depends on the desired balance of mechanical properties and functional enhancements in the final product.

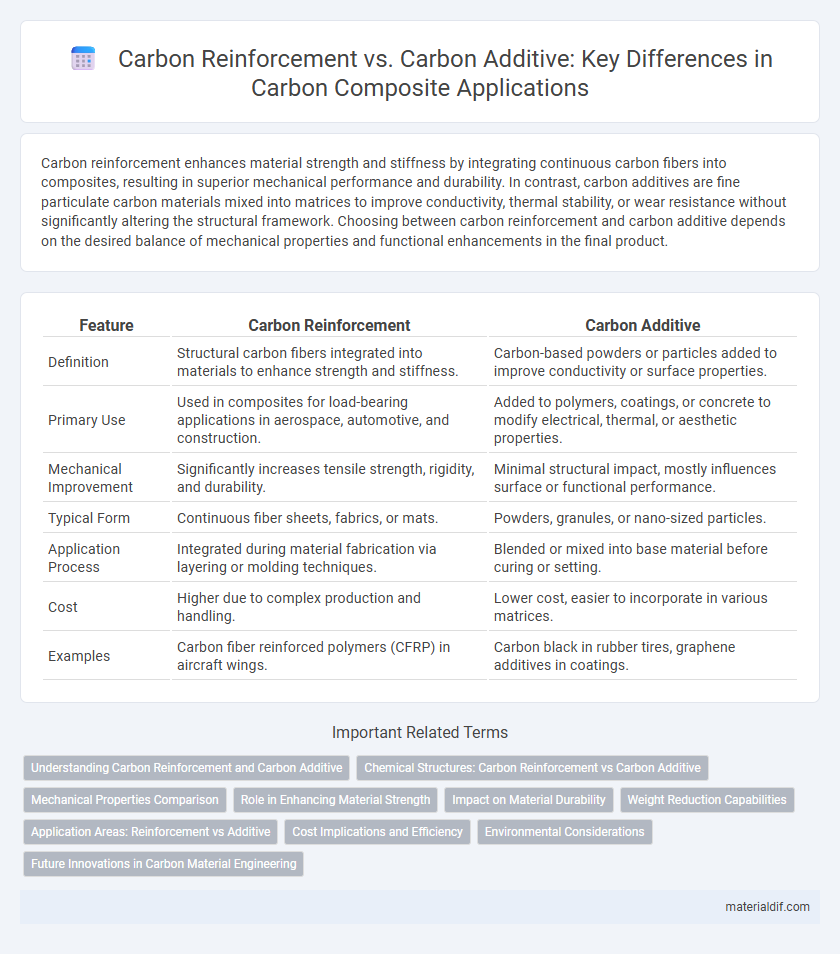

Table of Comparison

| Feature | Carbon Reinforcement | Carbon Additive |

|---|---|---|

| Definition | Structural carbon fibers integrated into materials to enhance strength and stiffness. | Carbon-based powders or particles added to improve conductivity or surface properties. |

| Primary Use | Used in composites for load-bearing applications in aerospace, automotive, and construction. | Added to polymers, coatings, or concrete to modify electrical, thermal, or aesthetic properties. |

| Mechanical Improvement | Significantly increases tensile strength, rigidity, and durability. | Minimal structural impact, mostly influences surface or functional performance. |

| Typical Form | Continuous fiber sheets, fabrics, or mats. | Powders, granules, or nano-sized particles. |

| Application Process | Integrated during material fabrication via layering or molding techniques. | Blended or mixed into base material before curing or setting. |

| Cost | Higher due to complex production and handling. | Lower cost, easier to incorporate in various matrices. |

| Examples | Carbon fiber reinforced polymers (CFRP) in aircraft wings. | Carbon black in rubber tires, graphene additives in coatings. |

Understanding Carbon Reinforcement and Carbon Additive

Carbon reinforcement enhances material strength and stiffness by integrating carbon fibers or fabrics into composites, significantly improving structural performance and durability in industries like aerospace and automotive. Carbon additives, on the other hand, are fine carbon particles or powders incorporated into polymers or metals to improve electrical conductivity, thermal stability, and wear resistance without substantially altering the primary mechanical framework. Understanding the distinct roles of carbon reinforcement and carbon additives enables optimized material design for advanced engineering applications, balancing mechanical enhancement with functional properties.

Chemical Structures: Carbon Reinforcement vs Carbon Additive

Carbon reinforcement utilizes carbon fibers composed of long, continuous chains of sp2 hybridized carbon atoms arranged in a hexagonal lattice, providing exceptional tensile strength and stiffness. Carbon additives, often in the form of carbon black or graphene nanoplatelets, consist of smaller particulate structures with varied degrees of crystallinity and surface functional groups that enhance composite conductivity and surface area. The chemical structure differences influence mechanical reinforcement by continuous anisotropic fibers versus property modification through dispersed particulate additives.

Mechanical Properties Comparison

Carbon reinforcement significantly enhances mechanical properties such as tensile strength, stiffness, and impact resistance by providing structural support within composite materials. In contrast, carbon additives primarily improve surface-level attributes like abrasion resistance and electrical conductivity but contribute less to load-bearing capacity. The integration of carbon reinforcement results in superior mechanical performance compared to carbon additives, making it ideal for demanding engineering applications.

Role in Enhancing Material Strength

Carbon reinforcement significantly improves material strength by integrating continuous carbon fibers that distribute stress evenly and increase tensile strength, stiffness, and fatigue resistance. Carbon additives, typically fine particles or powders, enhance strength by filling microvoids and improving matrix bonding without dramatically altering the material's structural framework. The reinforcement offers superior load-bearing capacity due to fiber alignment, while additives mainly optimize microstructural integrity and surface properties.

Impact on Material Durability

Carbon reinforcement significantly enhances material durability by increasing tensile strength and resistance to fatigue, making composites more robust under mechanical stress. Carbon additives improve wear resistance and thermal stability but do not provide the same structural reinforcement as carbon fibers. The integration of carbon reinforcement leads to longer-lasting materials in aerospace, automotive, and construction applications by effectively distributing loads and reducing crack propagation.

Weight Reduction Capabilities

Carbon reinforcement provides structural strength by integrating carbon fibers into composites, significantly reducing component weight while maintaining durability. Carbon additives, often in powder or nanoparticle form, enhance material properties but offer less dramatic weight reduction compared to fiber reinforcement. The superior load-bearing efficiency of carbon reinforcement makes it the preferred choice for lightweight applications in aerospace and automotive industries.

Application Areas: Reinforcement vs Additive

Carbon reinforcement enhances structural integrity and load-bearing capacity in construction, aerospace, and automotive industries by integrating carbon fibers or composites into materials. Carbon additives improve thermal conductivity, electrical properties, and chemical resistance in polymers, rubbers, and coatings, making them crucial in electronics, energy storage, and protective surfaces. Reinforcement primarily targets mechanical strength and durability, while additives optimize functional properties and performance characteristics in diverse manufacturing applications.

Cost Implications and Efficiency

Carbon reinforcement enhances material strength by integrating carbon fibers, leading to higher upfront costs but long-term durability and performance gains. Carbon additives, often cheaper, improve specific properties like conductivity or chemical resistance without significantly boosting structural integrity. The cost-efficiency balance depends on application demands, with reinforcement favored in load-bearing uses and additives preferred for cost-sensitive modifications.

Environmental Considerations

Carbon reinforcement enhances structural durability and lifespan, reducing the need for frequent replacements and lowering overall carbon emissions in construction. Carbon additives improve material properties like conductivity and strength but often require energy-intensive production processes, potentially increasing environmental impact. Choosing carbon reinforcement aligns better with sustainability goals due to its contribution to resource efficiency and reduced waste generation.

Future Innovations in Carbon Material Engineering

Future innovations in carbon material engineering emphasize the development of carbon reinforcement techniques, enhancing structural strength and durability in composites through optimized fiber alignment and hybridization. Carbon additives are being engineered at the nanoscale to improve electrical conductivity, thermal stability, and material resilience in polymers and metals. Advances in graphene integration and carbon nanotube dispersion are driving breakthroughs that combine reinforcement and additive properties, enabling multifunctional carbon-based materials for aerospace, automotive, and energy storage applications.

Carbon Reinforcement vs Carbon Additive Infographic

materialdif.com

materialdif.com