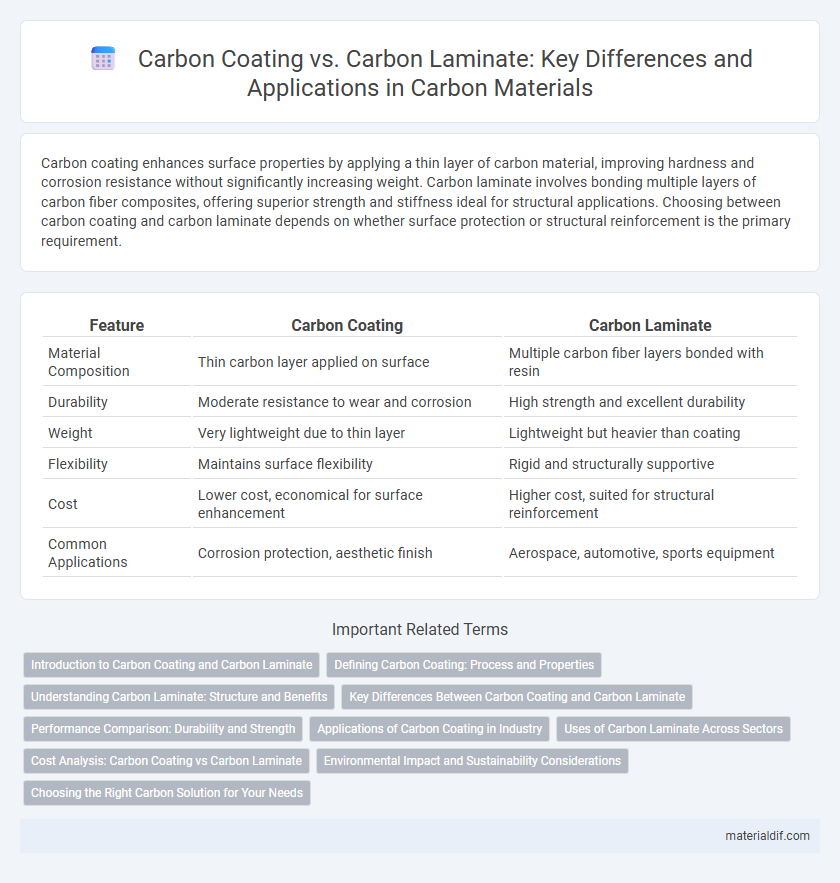

Carbon coating enhances surface properties by applying a thin layer of carbon material, improving hardness and corrosion resistance without significantly increasing weight. Carbon laminate involves bonding multiple layers of carbon fiber composites, offering superior strength and stiffness ideal for structural applications. Choosing between carbon coating and carbon laminate depends on whether surface protection or structural reinforcement is the primary requirement.

Table of Comparison

| Feature | Carbon Coating | Carbon Laminate |

|---|---|---|

| Material Composition | Thin carbon layer applied on surface | Multiple carbon fiber layers bonded with resin |

| Durability | Moderate resistance to wear and corrosion | High strength and excellent durability |

| Weight | Very lightweight due to thin layer | Lightweight but heavier than coating |

| Flexibility | Maintains surface flexibility | Rigid and structurally supportive |

| Cost | Lower cost, economical for surface enhancement | Higher cost, suited for structural reinforcement |

| Common Applications | Corrosion protection, aesthetic finish | Aerospace, automotive, sports equipment |

Introduction to Carbon Coating and Carbon Laminate

Carbon coating involves applying a thin layer of carbon material onto a surface to improve durability, corrosion resistance, and aesthetic appeal. Carbon laminate consists of multiple layers of carbon fiber sheets bonded together with resin, offering high strength-to-weight ratios and structural rigidity. Both technologies leverage carbon's exceptional mechanical properties but differ significantly in application methods and resulting functional benefits.

Defining Carbon Coating: Process and Properties

Carbon coating involves depositing a thin layer of carbon atoms onto a surface through techniques like chemical vapor deposition (CVD) or physical vapor deposition (PVD), enhancing hardness, corrosion resistance, and electrical conductivity. This process creates a uniform, adherent film that improves surface properties without significantly altering the substrate's bulk characteristics. Carbon coatings are widely used in industrial applications such as cutting tools, electronics, and wear-resistant components due to their excellent durability and thin, lightweight nature.

Understanding Carbon Laminate: Structure and Benefits

Carbon laminate consists of multiple layers of carbon fiber sheets bonded together with resin, creating a strong and lightweight composite material. This structure enhances durability and impact resistance while maintaining flexibility, making it ideal for automotive, aerospace, and sporting goods applications. Benefits include superior strength-to-weight ratio, corrosion resistance, and the ability to be molded into complex shapes for advanced design versatility.

Key Differences Between Carbon Coating and Carbon Laminate

Carbon coating involves applying a thin layer of carbon material onto a surface to enhance durability and resistance to wear, while carbon laminate consists of multiple carbon fiber layers bonded with resin to create a thicker, structural composite. Carbon coatings primarily improve surface properties such as scratch resistance and thermal protection, whereas carbon laminates contribute significantly to strength, stiffness, and lightweight structural integrity in applications like aerospace and automotive industries. The key difference lies in the functional purpose and thickness, with coatings serving surface enhancement and laminates providing mechanical reinforcement.

Performance Comparison: Durability and Strength

Carbon coating provides a thin, protective layer that enhances surface durability and resistance to abrasion, while carbon laminate offers superior structural strength due to its multiple bonded carbon fiber layers. Carbon laminate exhibits higher tensile strength and stiffness, making it ideal for load-bearing applications, whereas carbon coating improves wear resistance without significantly altering the material's mechanical properties. In performance-critical environments, carbon laminate outperforms carbon coating by delivering enhanced durability and long-term strength under dynamic stresses.

Applications of Carbon Coating in Industry

Carbon coating enhances wear resistance and corrosion protection across automotive and aerospace components, improving durability and performance. It is extensively applied in cutting tools and machinery parts to extend lifespan and reduce maintenance costs. The technology also plays a critical role in electronics, providing conductive layers for improved efficiency and heat dissipation.

Uses of Carbon Laminate Across Sectors

Carbon laminate finds extensive application across automotive, aerospace, sports equipment, and construction industries due to its lightweight strength and high durability. Its layered structure enhances impact resistance and fatigue strength, making it ideal for performance-driven parts like car panels, aircraft components, and protective sports gear. Compared to carbon coating, carbon laminate provides superior mechanical properties essential for structural use and long-term reliability in demanding environments.

Cost Analysis: Carbon Coating vs Carbon Laminate

Carbon coating typically incurs lower initial costs due to its thin application process and minimal material usage, making it a cost-effective option for enhancing surface properties. In contrast, carbon laminate demands higher investment because of the multiple layers of carbon fibers and resin, resulting in greater material and labor expenses. Long-term durability and performance benefits of carbon laminates can justify their premium cost, especially in high-stress or structural applications.

Environmental Impact and Sustainability Considerations

Carbon coating involves applying a thin layer of carbon to a surface, resulting in lower material usage and reduced waste compared to carbon laminates, which use multiple layers of carbon fiber embedded in resin. The production of carbon laminates typically requires more energy and generates higher carbon emissions due to the complex curing processes and resin content. Choosing carbon coatings over laminates can enhance sustainability by minimizing resource consumption and facilitating easier recycling or disposal, aligning better with environmental impact reduction goals.

Choosing the Right Carbon Solution for Your Needs

Carbon coating offers a thin, protective layer that enhances surface durability and corrosion resistance, ideal for applications requiring lightweight reinforcement without significant structural changes. Carbon laminate provides multiple layers of carbon fiber bonded with resin, delivering superior strength and stiffness for high-performance demands in aerospace, automotive, and sports equipment. Selecting the right carbon solution depends on the required mechanical properties, weight constraints, and environmental exposure specific to the intended use.

Carbon Coating vs Carbon Laminate Infographic

materialdif.com

materialdif.com