Carbon fiber offers superior tensile strength and lightweight properties ideal for aerospace and automotive applications, while graphite excels in thermal conductivity and electrical conductivity, making it valuable in battery electrodes and lubricants. Carbon fiber composites provide enhanced durability and stiffness compared to graphite materials. Choosing between carbon fiber and graphite depends on balancing mechanical performance requirements with thermal and electrical conductivity needs.

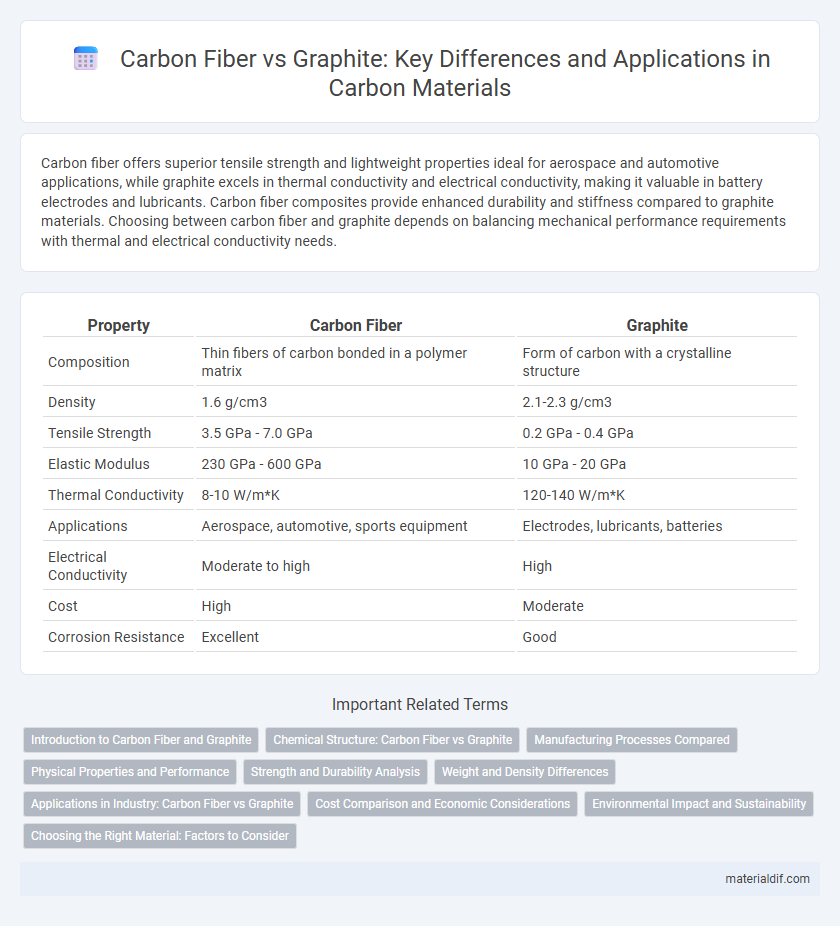

Table of Comparison

| Property | Carbon Fiber | Graphite |

|---|---|---|

| Composition | Thin fibers of carbon bonded in a polymer matrix | Form of carbon with a crystalline structure |

| Density | 1.6 g/cm3 | 2.1-2.3 g/cm3 |

| Tensile Strength | 3.5 GPa - 7.0 GPa | 0.2 GPa - 0.4 GPa |

| Elastic Modulus | 230 GPa - 600 GPa | 10 GPa - 20 GPa |

| Thermal Conductivity | 8-10 W/m*K | 120-140 W/m*K |

| Applications | Aerospace, automotive, sports equipment | Electrodes, lubricants, batteries |

| Electrical Conductivity | Moderate to high | High |

| Cost | High | Moderate |

| Corrosion Resistance | Excellent | Good |

Introduction to Carbon Fiber and Graphite

Carbon fiber is a lightweight, strong material made of thin strands of carbon atoms bonded in a crystalline structure, often used in aerospace and automotive industries for its high tensile strength and low weight. Graphite consists of layers of carbon atoms arranged in a hexagonal lattice, known for its excellent electrical conductivity and lubrication properties, commonly utilized in batteries, lubricants, and pencils. Despite both being made of carbon, carbon fiber exhibits superior mechanical strength, whereas graphite is favored for thermal stability and electrical applications.

Chemical Structure: Carbon Fiber vs Graphite

Carbon fiber consists of long chains of carbon atoms bonded in a polymer matrix, forming strong and flexible fibers with an amorphous structure. Graphite features layers of carbon atoms arranged in a hexagonal lattice with strong covalent bonds within layers and weak van der Waals forces between layers, providing excellent electrical conductivity and lubricity. The distinct chemical bonding and structural differences between carbon fiber and graphite result in divergent mechanical and electrical properties, impacting their respective applications.

Manufacturing Processes Compared

Carbon fiber manufacturing involves the pyrolysis of polyacrylonitrile (PAN) or pitch precursors, followed by stretching and heat treatment to align carbon atoms into strong, lightweight fibers. Graphite production typically requires high-temperature graphitization of carbonized materials, often derived from coke or synthetic precursors, resulting in crystalline structures with high electrical conductivity. The carbon fiber process emphasizes tensile strength and flexibility for composite applications, while graphite manufacturing targets structural and conductive properties through controlled thermal treatments.

Physical Properties and Performance

Carbon fiber exhibits higher tensile strength and greater stiffness compared to graphite, making it ideal for structural applications requiring durability and lightweight materials. Graphite boasts superior thermal conductivity and electrical properties due to its crystalline structure, which enhances performance in heat dissipation and electronic applications. The anisotropic nature of carbon fiber offers directional strength advantages, while graphite's layered molecular arrangement allows for effective lubrication and improved wear resistance.

Strength and Durability Analysis

Carbon fiber exhibits superior tensile strength and fatigue resistance compared to graphite, making it an ideal material for high-performance applications. Its molecular structure allows for enhanced durability under cyclic loads, outperforming the more brittle nature of graphite. These properties position carbon fiber as the preferred choice in aerospace, automotive, and sporting goods industries where strength-to-weight ratio is critical.

Weight and Density Differences

Carbon fiber exhibits a significantly lower density of approximately 1.6 g/cm3 compared to graphite's density, which ranges from 2.0 to 2.3 g/cm3. This weight difference makes carbon fiber the preferred material in aerospace and automotive industries where lightweight strength is critical. Graphite's higher density contributes to its superior thermal conductivity but results in heavier components.

Applications in Industry: Carbon Fiber vs Graphite

Carbon fiber excels in aerospace, automotive, and sporting goods industries due to its high strength-to-weight ratio and corrosion resistance. Graphite is predominantly used in electronics, batteries, and lubricants for its electrical conductivity and thermal stability. While both materials contribute to industrial innovation, carbon fiber's structural applications contrast with graphite's functionality in energy storage and heat management.

Cost Comparison and Economic Considerations

Carbon fiber typically costs between $10 and $20 per pound, while graphite tends to be more affordable, ranging from $5 to $15 per pound depending on quality and grade. The higher cost of carbon fiber is attributed to its complex manufacturing process and superior strength-to-weight ratio, making it ideal for high-performance applications despite the price premium. Economic considerations favor graphite for budget-sensitive projects, whereas carbon fiber is preferred in industries like aerospace and automotive where durability and lightweight properties justify the investment.

Environmental Impact and Sustainability

Carbon fiber and graphite differ significantly in environmental impact and sustainability, with carbon fiber production consuming high amounts of energy and generating hazardous waste, thus posing challenges for eco-friendly disposal and recycling. Graphite, often mined naturally, involves environmental degradation from mining activities but can be more readily recycled and reused in various industries. Innovations in bio-based carbon fiber and synthetic graphite aim to reduce ecological footprints, enhancing the sustainability profiles of both materials.

Choosing the Right Material: Factors to Consider

Choosing between carbon fiber and graphite depends on key factors such as strength-to-weight ratio, stiffness, and application-specific demands. Carbon fiber offers superior tensile strength and flexibility, making it ideal for dynamic load environments, while graphite provides higher stiffness and excellent electrical conductivity suitable for precision instruments. Cost and fabrication methods also influence material selection, with carbon fiber generally requiring more complex manufacturing processes compared to graphite.

Carbon fiber vs Graphite Infographic

materialdif.com

materialdif.com