Conductive carbon provides excellent electrical conductivity, making it ideal for applications requiring efficient current flow or static dissipation. Structural carbon, on the other hand, is engineered for high strength and stiffness, enhancing mechanical performance in load-bearing components. Balancing these properties is essential for optimizing carbon PET composites in advanced engineering and electronics.

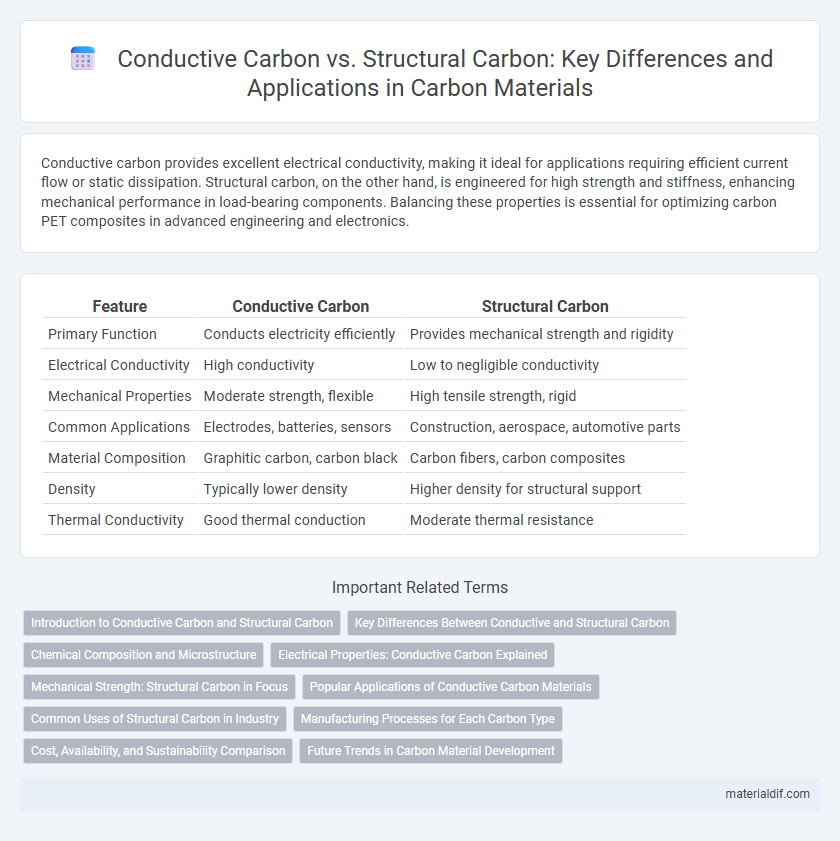

Table of Comparison

| Feature | Conductive Carbon | Structural Carbon |

|---|---|---|

| Primary Function | Conducts electricity efficiently | Provides mechanical strength and rigidity |

| Electrical Conductivity | High conductivity | Low to negligible conductivity |

| Mechanical Properties | Moderate strength, flexible | High tensile strength, rigid |

| Common Applications | Electrodes, batteries, sensors | Construction, aerospace, automotive parts |

| Material Composition | Graphitic carbon, carbon black | Carbon fibers, carbon composites |

| Density | Typically lower density | Higher density for structural support |

| Thermal Conductivity | Good thermal conduction | Moderate thermal resistance |

Introduction to Conductive Carbon and Structural Carbon

Conductive carbon primarily enhances electrical conductivity in composites, utilizing types such as carbon black, graphite, and carbon nanotubes to facilitate electron transport. Structural carbon emphasizes mechanical strength and stiffness, exemplified by carbon fibers and carbon nanotube composites in load-bearing applications. Both forms leverage carbon's unique atomic bonds but differ significantly in their functional roles within advanced materials.

Key Differences Between Conductive and Structural Carbon

Conductive carbon is primarily utilized for its excellent electrical conductivity, making it essential in applications like batteries, electrodes, and electronic devices, whereas structural carbon is valued for its mechanical strength and lightweight properties, commonly used in aerospace, automotive, and construction industries. The key differences lie in their material composition and functional properties; conductive carbon often includes forms like carbon black and graphite tailored for electron transfer, while structural carbon involves carbon fibers and composites engineered for load-bearing and durability. Understanding these distinctions is crucial for selecting the appropriate carbon type based on whether conductivity or structural integrity is the priority in a given application.

Chemical Composition and Microstructure

Conductive carbon is typically composed of graphite-like microstructures with sp2 hybridized carbon atoms arranged in hexagonal lattices, enabling high electrical conductivity. Structural carbon, often found in carbon fibers, consists of more amorphous or turbostratic carbon with a mix of sp2 and sp3 bonds, providing mechanical strength and stiffness. The chemical composition differences and microstructural arrangement directly influence their functional properties, with conductive carbon optimized for electron flow and structural carbon designed to withstand mechanical stresses.

Electrical Properties: Conductive Carbon Explained

Conductive carbon materials, such as carbon black and graphene, exhibit high electrical conductivity due to their sp2 hybridized carbon atoms forming delocalized pi-electron networks. In contrast, structural carbon, including carbon fibers and graphite, primarily provides mechanical strength with limited electrical conductivity. The superior electron mobility in conductive carbon makes it essential for applications in batteries, supercapacitors, and electronic devices.

Mechanical Strength: Structural Carbon in Focus

Structural carbon exhibits superior mechanical strength compared to conductive carbon, making it ideal for applications requiring durability and load-bearing capacity. Its graphite-based microstructure enhances tensile strength and stiffness, allowing it to withstand significant mechanical stress. Conductive carbon prioritizes electrical conductivity over mechanical properties, resulting in lower structural integrity.

Popular Applications of Conductive Carbon Materials

Conductive carbon materials, known for their excellent electrical conductivity and lightweight properties, are widely used in energy storage devices such as supercapacitors and lithium-ion batteries. These materials also play a critical role in electromagnetic interference (EMI) shielding for electronic devices and in printable electronics for flexible circuits. Their unique combination of conductivity and mechanical flexibility makes them ideal for wearable technology and advanced sensor applications.

Common Uses of Structural Carbon in Industry

Structural carbon is widely used in aerospace, automotive, and construction industries due to its exceptional strength-to-weight ratio and durability. Components such as aircraft frames, automotive body panels, and high-performance sporting goods benefit from its high tensile strength and resistance to fatigue. Its ability to maintain structural integrity under extreme conditions makes it ideal for critical load-bearing applications.

Manufacturing Processes for Each Carbon Type

Conductive carbon is typically manufactured through high-temperature pyrolysis of carbon-rich precursors like pitch or polymers to enhance electrical conductivity by creating a graphitic microstructure. Structural carbon is produced via carbonization and graphitization of materials such as carbon fibers or composite resins, emphasizing mechanical strength and stiffness through controlled fiber alignment and matrix curing. Each process involves precise thermal treatments and precursor selection tailored to optimize either electrical properties for conductive carbon or mechanical performance for structural carbon.

Cost, Availability, and Sustainability Comparison

Conductive carbon typically costs less than structural carbon due to simpler manufacturing processes and higher availability, making it a practical choice for applications requiring electrical conductivity. Structural carbon, known for its superior strength and stiffness, commands a higher price driven by complex fabrication methods and limited raw material sources. Both types pose sustainability challenges; conductive carbon often uses less energy-intensive materials, while structural carbon production demands significant energy inputs but can be optimized by recycling and renewable feedstocks.

Future Trends in Carbon Material Development

Future trends in carbon material development emphasize the integration of conductive carbon variants such as graphene and carbon nanotubes to enhance electrical performance in energy storage and flexible electronics. Structural carbon materials continue to evolve with advancements in carbon fiber composites, enabling lighter and stronger components for aerospace and automotive applications. Emerging hybrid carbon materials aim to combine the conductivity of conductive carbon with the mechanical strength of structural carbon, driving innovation in multifunctional materials.

Conductive Carbon vs Structural Carbon Infographic

materialdif.com

materialdif.com