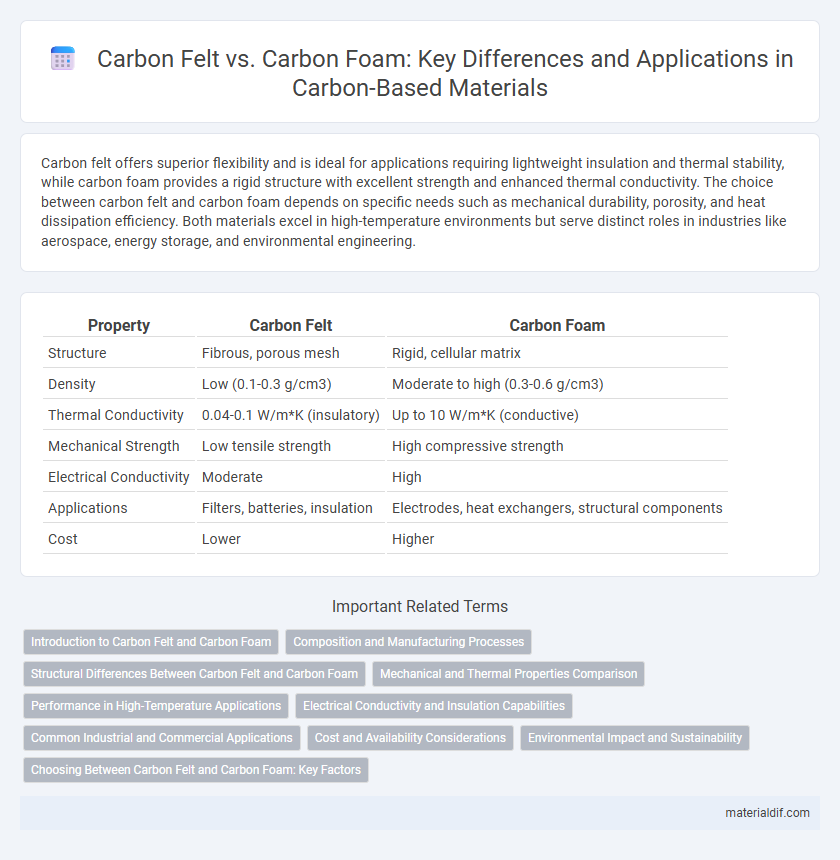

Carbon felt offers superior flexibility and is ideal for applications requiring lightweight insulation and thermal stability, while carbon foam provides a rigid structure with excellent strength and enhanced thermal conductivity. The choice between carbon felt and carbon foam depends on specific needs such as mechanical durability, porosity, and heat dissipation efficiency. Both materials excel in high-temperature environments but serve distinct roles in industries like aerospace, energy storage, and environmental engineering.

Table of Comparison

| Property | Carbon Felt | Carbon Foam |

|---|---|---|

| Structure | Fibrous, porous mesh | Rigid, cellular matrix |

| Density | Low (0.1-0.3 g/cm3) | Moderate to high (0.3-0.6 g/cm3) |

| Thermal Conductivity | 0.04-0.1 W/m*K (insulatory) | Up to 10 W/m*K (conductive) |

| Mechanical Strength | Low tensile strength | High compressive strength |

| Electrical Conductivity | Moderate | High |

| Applications | Filters, batteries, insulation | Electrodes, heat exchangers, structural components |

| Cost | Lower | Higher |

Introduction to Carbon Felt and Carbon Foam

Carbon felt consists of entangled carbon fibers forming a porous and flexible material widely used for high-temperature insulation and filtration applications. Carbon foam is a rigid, lightweight structure with interconnected voids, offering excellent thermal conductivity and mechanical strength, ideal for heat exchange and energy storage. Both materials leverage carbon's properties but differ significantly in morphology and functional applications.

Composition and Manufacturing Processes

Carbon felt is composed of interwoven carbon fibers typically produced through a needling process that entangles fibers into a dense mat, while carbon foam consists of a porous, cellular structure formed by carbonization of polymeric foam precursors. The manufacturing of carbon felt involves fiber stabilization, carbonization, and sometimes graphitization to enhance thermal and electrical properties. In contrast, carbon foam fabrication includes polymer foam replication followed by controlled pyrolysis, creating a lightweight material with high surface area and excellent thermal insulation.

Structural Differences Between Carbon Felt and Carbon Foam

Carbon felt consists of interwoven carbon fibers forming a porous, flexible mat with high tensile strength, while carbon foam features a rigid, cellular structure with interconnected pores providing lightweight support and high compressive strength. The felt's fibrous network enhances flexibility and shock absorption, contrasting with the foam's solid matrix that delivers superior structural integrity and thermal insulation. These fundamental differences influence their applications in aerospace, energy storage, and filtration systems.

Mechanical and Thermal Properties Comparison

Carbon felt offers high thermal insulation and excellent flexibility, making it suitable for applications requiring lightweight and compressible materials. Carbon foam exhibits superior mechanical strength and structural rigidity with enhanced thermal conductivity, ideal for load-bearing components exposed to heat. The choice between carbon felt and carbon foam depends on specific requirements for thermal resistance versus mechanical durability in high-temperature environments.

Performance in High-Temperature Applications

Carbon felt offers superior thermal insulation and resilience in high-temperature environments due to its fibrous structure that traps air, making it ideal for furnace linings and heat shields. Carbon foam, with its rigid and porous matrix, provides excellent mechanical strength and efficient heat dissipation, suitable for applications requiring both thermal management and structural support. Performance in extreme heat varies as carbon felt excels in insulating and flexibility, whereas carbon foam is preferred for durability and conductive thermal performance.

Electrical Conductivity and Insulation Capabilities

Carbon felt exhibits high electrical conductivity due to its interconnected carbon fiber network, making it suitable for applications requiring efficient current transfer. In contrast, carbon foam offers lower electrical conductivity while providing superior thermal insulation because of its porous, open-cell structure that minimizes heat transfer. These distinctions make carbon felt ideal for electrodes and conductive materials, whereas carbon foam is preferred for insulation in high-temperature environments.

Common Industrial and Commercial Applications

Carbon felt is widely used in high-temperature filtration, thermal insulation, and electrochemical applications such as battery electrodes and fuel cells due to its excellent thermal stability and porosity. Carbon foam, known for its lightweight structure and high thermal conductivity, is commonly applied in heat exchangers, catalytic converters, and as a structural material in aerospace and automotive industries. Both materials play critical roles in energy storage, environmental control, and advanced manufacturing processes.

Cost and Availability Considerations

Carbon felt is generally more affordable and widely available due to its simpler manufacturing processes and extensive use in filtration and insulation industries. Carbon foam, while offering superior structural integrity and thermal conductivity, tends to be more expensive and less readily available, primarily produced for specialized applications like aerospace and energy storage. Cost considerations pivot on the scale of production and performance requirements, with carbon felt favored for budget-conscious, high-volume uses.

Environmental Impact and Sustainability

Carbon felt and carbon foam differ significantly in environmental impact and sustainability. Carbon felt, often derived from natural fibers or bio-based precursors, offers better biodegradability and lower energy consumption during production compared to carbon foam, which typically involves energy-intensive manufacturing with synthetic polymers. The recyclability and potential for reuse of carbon felt also contribute to its more sustainable profile relative to carbon foam's limited end-of-life options.

Choosing Between Carbon Felt and Carbon Foam: Key Factors

Choosing between carbon felt and carbon foam depends on factors such as thermal conductivity, porosity, and mechanical strength. Carbon felt offers superior thermal insulation and flexibility, making it ideal for high-temperature applications, while carbon foam provides higher structural support and better heat dissipation due to its porous, rigid matrix. The selection should align with specific use cases like furnace insulation, catalyst supports, or filtration systems where material performance directly affects efficiency.

Carbon Felt vs Carbon Foam Infographic

materialdif.com

materialdif.com