Carbon black consists of fine particulate carbon used primarily as a reinforcing filler in rubber and as a pigment, offering excellent abrasion resistance and conductivity. Carbon fiber, composed of thin, strong crystalline carbon strands, excels in lightweight structural applications due to its high tensile strength and stiffness. Both materials are crucial in manufacturing but serve distinct roles based on their physical properties and performance characteristics.

Table of Comparison

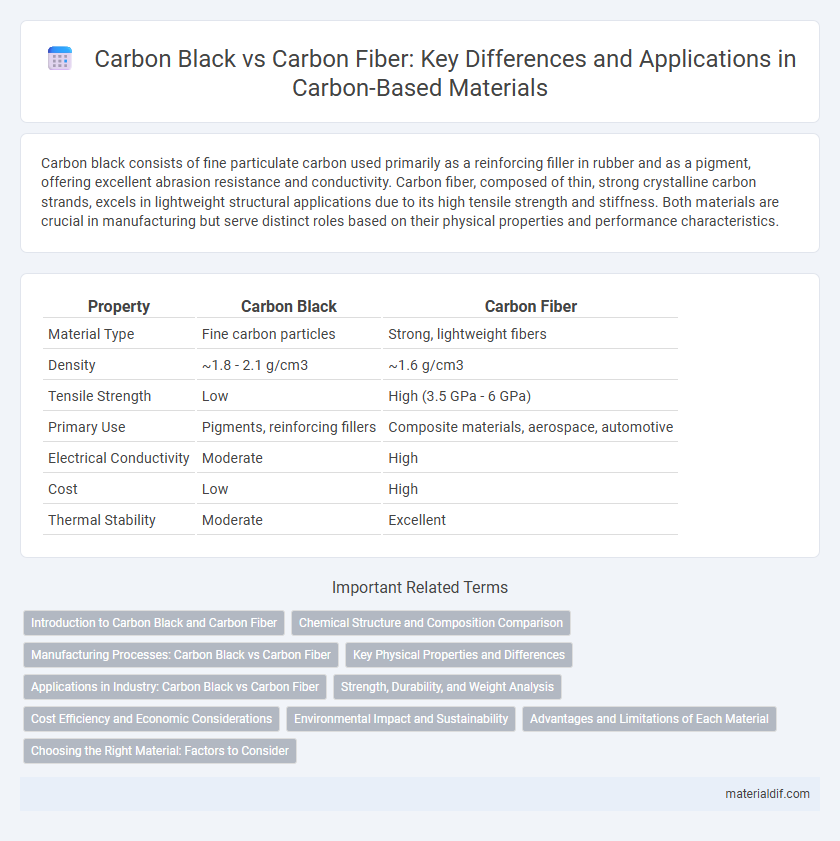

| Property | Carbon Black | Carbon Fiber |

|---|---|---|

| Material Type | Fine carbon particles | Strong, lightweight fibers |

| Density | ~1.8 - 2.1 g/cm3 | ~1.6 g/cm3 |

| Tensile Strength | Low | High (3.5 GPa - 6 GPa) |

| Primary Use | Pigments, reinforcing fillers | Composite materials, aerospace, automotive |

| Electrical Conductivity | Moderate | High |

| Cost | Low | High |

| Thermal Stability | Moderate | Excellent |

Introduction to Carbon Black and Carbon Fiber

Carbon black is a fine carbon powder primarily used as a reinforcing filler in rubber products, especially tires, enhancing durability and wear resistance. Carbon fiber consists of thin, strong crystalline filaments of carbon, widely utilized in aerospace, automotive, and sports equipment for its high strength-to-weight ratio. Both materials originate from carbon but exhibit distinct physical structures and industrial applications.

Chemical Structure and Composition Comparison

Carbon black is composed of nearly pure elemental carbon arranged in an amorphous, quasi-spherical nanoparticle form with a high surface area, primarily used as a reinforcing filler. Carbon fiber consists of long, thin crystalline filaments of carbon atoms aligned in a hexagonal lattice, providing exceptional tensile strength and stiffness due to its graphitic structure. The difference in chemical structure--amorphous carbon in carbon black versus graphitic crystalline carbon in carbon fiber--dictates their distinct mechanical properties and applications.

Manufacturing Processes: Carbon Black vs Carbon Fiber

Carbon black is produced through the incomplete combustion of heavy petroleum products, leading to fine particulate clusters used primarily as a reinforcing agent in rubber and pigments in inks and coatings. Carbon fiber manufacturing involves the carbonization of polyacrylonitrile (PAN), pitch, or rayon fibers at high temperatures in an inert atmosphere, creating strong, lightweight materials with high tensile strength and stiffness. The distinct production methods directly influence their applications: carbon black's particulate nature suits surface treatment and pigmentation, while carbon fiber's fibrous structure is essential for aerospace, automotive, and sports equipment composites.

Key Physical Properties and Differences

Carbon black is a fine, black powder primarily used as a reinforcing filler in rubber products, exhibiting high surface area and excellent conductivity but lacking structural strength. Carbon fiber, composed of thin strands of carbon atoms bonded in a crystalline structure, offers exceptional tensile strength, stiffness, and low weight, making it ideal for aerospace and automotive applications. Unlike carbon black, carbon fiber provides superior mechanical performance and durability, though it is significantly more expensive and less conductive.

Applications in Industry: Carbon Black vs Carbon Fiber

Carbon black is primarily used as a reinforcing filler in rubber products, especially in tires, enhancing durability and wear resistance in automotive and industrial applications. Carbon fiber is favored in aerospace, automotive, and sporting goods industries for its high strength-to-weight ratio, providing lightweight structural components with superior mechanical performance. While carbon black improves material toughness and electrical conductivity, carbon fiber offers exceptional stiffness and tensile strength for advanced engineering uses.

Strength, Durability, and Weight Analysis

Carbon fiber exhibits superior strength-to-weight ratio compared to carbon black, making it ideal for applications requiring lightweight and high-strength materials such as aerospace and automotive components. Carbon fiber's durable composite structure resists fatigue and environmental degradation better than carbon black, which is primarily used as a reinforcing filler in rubber and plastic but lacks structural integrity on its own. Weight analysis shows carbon fiber significantly reduces component mass while maintaining mechanical performance, whereas carbon black's contribution to weight reduction is minimal and focuses more on enhancing material properties.

Cost Efficiency and Economic Considerations

Carbon black offers a cost-efficient solution due to its lower manufacturing expenses and widespread availability compared to carbon fiber. While carbon fiber provides superior strength-to-weight ratios, its higher production costs and energy-intensive processes make it less economically viable for mass-market applications. Evaluating long-term economic considerations, carbon black is often preferred for cost-sensitive projects requiring reinforcement or pigmentation rather than structural performance.

Environmental Impact and Sustainability

Carbon black, primarily used as a reinforcing filler in tires and plastics, is produced through the incomplete combustion of heavy petroleum products, resulting in significant carbon emissions and environmental pollution. Carbon fiber, made from polyacrylonitrile (PAN) or pitch, offers high strength-to-weight ratio and durability, contributing to fuel efficiency in transportation, but its production is energy-intensive and involves non-renewable resources. Sustainable alternatives and recycling methods for carbon fiber are emerging to reduce its environmental impact, while advancements in cleaner production techniques for carbon black aim to minimize pollution and carbon footprint.

Advantages and Limitations of Each Material

Carbon fiber offers exceptional strength-to-weight ratio and high stiffness, making it ideal for aerospace and automotive applications, but it is brittle and costly to produce. Carbon black, primarily used as a reinforcing filler in rubber and plastics, enhances durability and UV resistance while being cost-effective, though it lacks structural strength. Choosing between carbon fiber and carbon black depends on whether lightweight strength or material reinforcement is the design priority.

Choosing the Right Material: Factors to Consider

Carbon black enhances material durability and conductivity, making it ideal for reinforcing rubber and plastics in automotive and electronic applications. Carbon fiber offers superior strength-to-weight ratio and stiffness, preferred in aerospace and sports equipment for lightweight structural support. Choosing between carbon black and carbon fiber depends on specific performance needs such as flexibility, tensile strength, electrical conductivity, and cost-efficiency in manufacturing.

Carbon Black vs Carbon Fiber Infographic

materialdif.com

materialdif.com