Carbon foam offers a lightweight, porous structure with high thermal insulation and improved mechanical strength, making it ideal for aerospace and automotive applications. Carbon felt provides superior flexibility, excellent electrical conductivity, and resistance to chemical corrosion, often used in battery electrodes and filtration systems. Choosing between carbon foam and carbon felt depends on the specific requirements for thermal management, mechanical durability, and electrical performance.

Table of Comparison

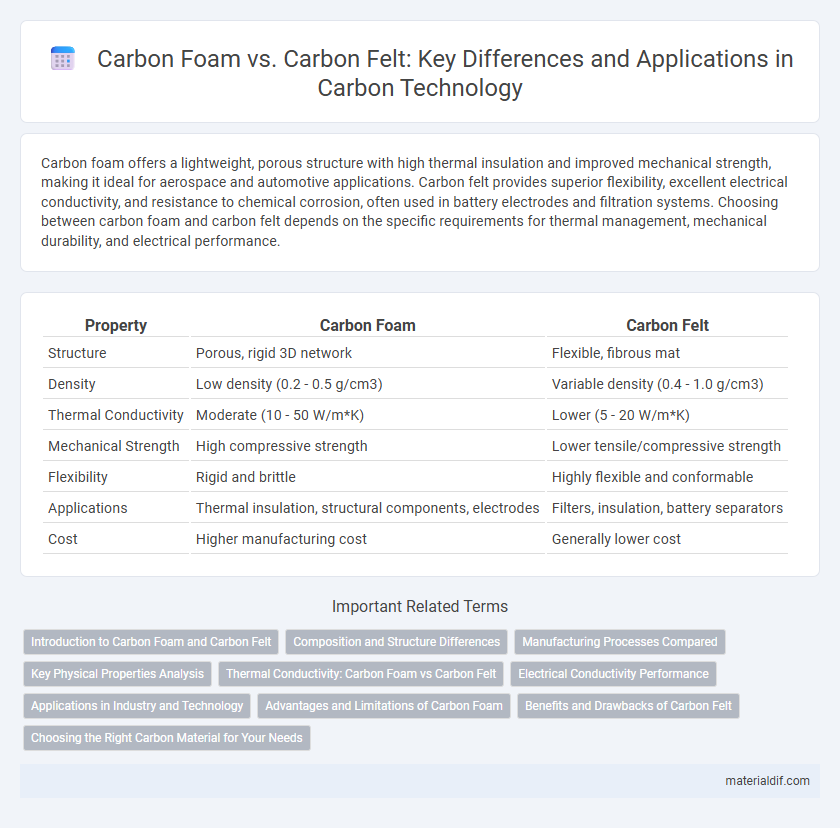

| Property | Carbon Foam | Carbon Felt |

|---|---|---|

| Structure | Porous, rigid 3D network | Flexible, fibrous mat |

| Density | Low density (0.2 - 0.5 g/cm3) | Variable density (0.4 - 1.0 g/cm3) |

| Thermal Conductivity | Moderate (10 - 50 W/m*K) | Lower (5 - 20 W/m*K) |

| Mechanical Strength | High compressive strength | Lower tensile/compressive strength |

| Flexibility | Rigid and brittle | Highly flexible and conformable |

| Applications | Thermal insulation, structural components, electrodes | Filters, insulation, battery separators |

| Cost | Higher manufacturing cost | Generally lower cost |

Introduction to Carbon Foam and Carbon Felt

Carbon foam is a porous, lightweight material known for its high thermal conductivity and mechanical strength, often used in aerospace and thermal insulation applications. Carbon felt is a flexible, fibrous material with excellent heat resistance and electrical conductivity, commonly utilized in filtration, battery electrodes, and heater elements. Both materials exhibit unique microstructures tailored for specific industrial uses, making them essential in advanced carbon-based technologies.

Composition and Structure Differences

Carbon foam consists of a rigid, porous matrix formed by interconnected carbon cells, providing high strength and thermal insulation due to its uniform pore distribution. Carbon felt is composed of randomly oriented carbon fibers entangled into a flexible mat, offering superior surface area and enhanced conductivity for filtration and catalyst support. The structural disparity between the foam's monolithic cellular framework and the felt's fibrous network directly influences their performance in energy storage and aerospace applications.

Manufacturing Processes Compared

Carbon foam is produced through a polymeric precursor process involving high-temperature pyrolysis and foaming agents, resulting in a lightweight, porous structure with controlled pore size. Carbon felt manufacturing typically includes carbonization and graphitization of woven or nonwoven carbon fibers, yielding a flexible, fibrous mat with high surface area. The distinct processes determine the materials' applications, with foam suited for structural insulation and felt preferred for filtration and thermal management.

Key Physical Properties Analysis

Carbon foam exhibits a highly porous structure with low density and excellent thermal insulation, making it ideal for lightweight applications requiring heat resistance. In contrast, carbon felt features a non-woven fabric form with higher flexibility and superior compressive strength, suited for filtration and electrode supports in energy storage. Both materials demonstrate high thermal stability and conductivity, but carbon foam excels in structural rigidity, while carbon felt offers better conformity and mechanical resilience.

Thermal Conductivity: Carbon Foam vs Carbon Felt

Carbon foam exhibits higher thermal conductivity due to its interconnected porous structure, allowing efficient heat transfer compared to carbon felt, which has a more fibrous and less dense matrix. The thermal conductivity of carbon foam typically ranges from 10 to 50 W/m*K, while carbon felt usually measures between 1 to 5 W/m*K. This significant difference makes carbon foam more suitable for applications requiring rapid heat dissipation, whereas carbon felt is often used for insulation or filtration purposes.

Electrical Conductivity Performance

Carbon foam exhibits higher electrical conductivity than carbon felt due to its interconnected porous structure enabling efficient electron transport and lower electrical resistance. Carbon felt, while flexible and versatile, has a less uniform microstructure that results in relatively lower conductivity. Advanced carbon foam materials demonstrate conductivity values exceeding 1000 S/m, significantly outperforming typical carbon felt conductivities around 100-300 S/m.

Applications in Industry and Technology

Carbon foam exhibits high thermal insulation and mechanical strength, making it ideal for aerospace components and thermal management systems in electronics. Carbon felt offers superior electrical conductivity and flexibility, widely used in fuel cells, batteries, and filtration systems. Both materials enhance performance in industrial applications, with carbon foam preferred for structural support and carbon felt favored for electrochemical processes.

Advantages and Limitations of Carbon Foam

Carbon foam offers superior thermal insulation and lightweight strength compared to carbon felt, making it ideal for aerospace and automotive applications requiring efficient heat resistance and structural integrity. Its porous structure provides enhanced energy absorption and acoustic damping but can be limited by brittleness and higher manufacturing costs. The foam's rigidity contrasts with carbon felt's flexibility, restricting its use in applications where conformability and ease of shaping are critical.

Benefits and Drawbacks of Carbon Felt

Carbon felt offers excellent thermal insulation and chemical resistance, making it ideal for high-temperature applications such as filtration and reinforcement in composite materials. Its flexible, lightweight structure allows for easy handling and adaptability, but it tends to have lower mechanical strength and durability compared to carbon foam. Carbon felt's higher cost and susceptibility to compression can limit its use in structural applications requiring long-term stability.

Choosing the Right Carbon Material for Your Needs

Carbon foam offers high thermal conductivity and structural strength, making it ideal for heat exchangers and lightweight insulation applications. Carbon felt provides superior flexibility and compressibility, suitable for filtration, gasketing, and thermal insulation in irregular shapes. Selecting the right carbon material depends on specific performance requirements such as thermal management, mechanical strength, and form factor adaptability.

Carbon Foam vs Carbon Felt Infographic

materialdif.com

materialdif.com