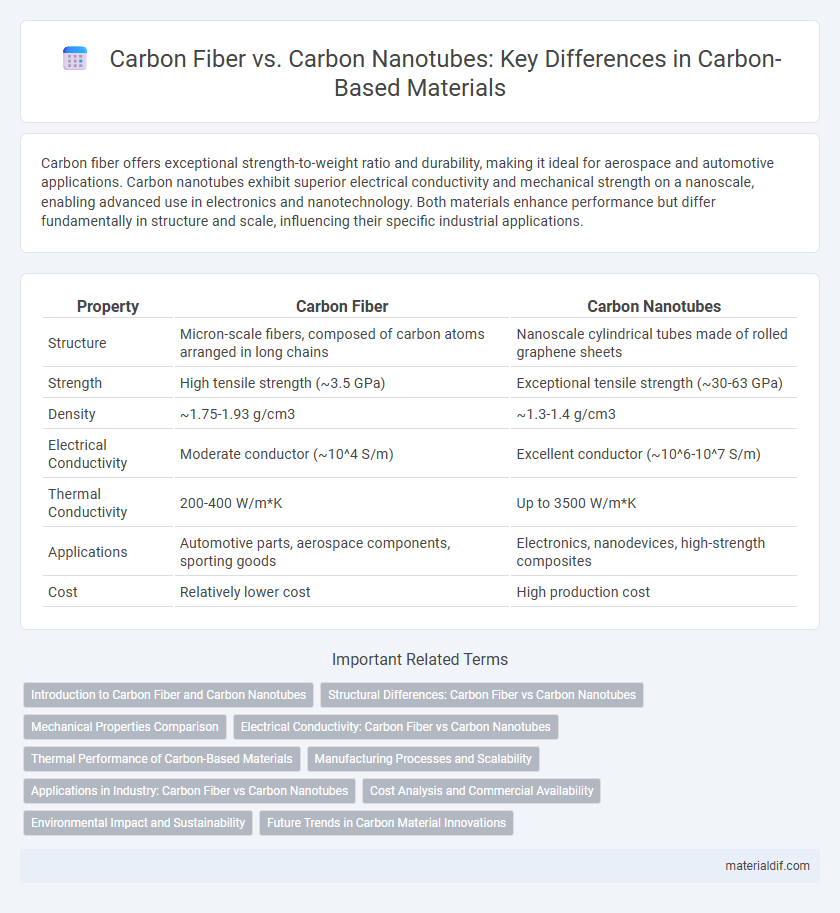

Carbon fiber offers exceptional strength-to-weight ratio and durability, making it ideal for aerospace and automotive applications. Carbon nanotubes exhibit superior electrical conductivity and mechanical strength on a nanoscale, enabling advanced use in electronics and nanotechnology. Both materials enhance performance but differ fundamentally in structure and scale, influencing their specific industrial applications.

Table of Comparison

| Property | Carbon Fiber | Carbon Nanotubes |

|---|---|---|

| Structure | Micron-scale fibers, composed of carbon atoms arranged in long chains | Nanoscale cylindrical tubes made of rolled graphene sheets |

| Strength | High tensile strength (~3.5 GPa) | Exceptional tensile strength (~30-63 GPa) |

| Density | ~1.75-1.93 g/cm3 | ~1.3-1.4 g/cm3 |

| Electrical Conductivity | Moderate conductor (~10^4 S/m) | Excellent conductor (~10^6-10^7 S/m) |

| Thermal Conductivity | 200-400 W/m*K | Up to 3500 W/m*K |

| Applications | Automotive parts, aerospace components, sporting goods | Electronics, nanodevices, high-strength composites |

| Cost | Relatively lower cost | High production cost |

Introduction to Carbon Fiber and Carbon Nanotubes

Carbon fiber consists of thin, strong crystalline filaments of carbon atoms, widely used for its high strength-to-weight ratio and rigidity in aerospace, automotive, and sporting goods. Carbon nanotubes are cylindrical nanostructures made of rolled graphene sheets, exhibiting extraordinary mechanical strength, electrical conductivity, and thermal properties at the nanoscale. Both materials derive from carbon but differ significantly in structure, scale, and application potential, with nanotubes offering superior performance in nanotechnology and electronics.

Structural Differences: Carbon Fiber vs Carbon Nanotubes

Carbon fiber consists of long, thin strands of carbon atoms bonded in a crystalline structure, typically 5-10 microns in diameter, providing high tensile strength and stiffness used in aerospace and automotive industries. Carbon nanotubes are cylindrical molecules with diameters as small as one nanometer, composed of rolled graphene sheets, exhibiting exceptional tensile strength and electrical conductivity at the nanoscale. The key structural difference lies in carbon fiber's bulk micro-scale fibers versus carbon nanotubes' nanoscale hollow tubes, influencing their mechanical properties and applications.

Mechanical Properties Comparison

Carbon fiber exhibits high tensile strength and stiffness, making it ideal for lightweight structural components with enhanced durability. Carbon nanotubes surpass carbon fiber with exceptional tensile strength up to 100 times greater and superior elasticity, offering remarkable mechanical resilience at the nanoscale. The integration of carbon nanotubes can significantly improve composite materials' strength-to-weight ratio and impact resistance compared to traditional carbon fiber.

Electrical Conductivity: Carbon Fiber vs Carbon Nanotubes

Carbon nanotubes exhibit significantly higher electrical conductivity than traditional carbon fibers due to their unique cylindrical nanostructure and seamless graphene lattice, enabling efficient electron transport. While carbon fibers serve as lightweight conductive materials in composites, their conductivity is limited by microstructural defects and fiber orientation. Advanced applications requiring superior electrical performance prioritize carbon nanotubes for their exceptional conductivity, reaching conductivities up to 10^6 S/m compared to typical carbon fiber conductivities around 10^4 S/m.

Thermal Performance of Carbon-Based Materials

Carbon fiber exhibits high thermal conductivity ranging from 8 to 50 W/mK, which enhances heat dissipation in composite materials used in aerospace and automotive industries. Carbon nanotubes demonstrate superior thermal conductivity exceeding 3000 W/mK along their axis, making them highly effective for thermal management in electronics and advanced materials. The enhanced phonon transport properties in carbon nanotubes provide significant advantages over carbon fibers for applications requiring rapid heat transfer and thermal stability.

Manufacturing Processes and Scalability

Carbon fiber manufacturing involves the pyrolysis of precursor fibers such as polyacrylonitrile (PAN) or pitch, followed by oxidation and carbonization, enabling large-scale production with consistent mechanical properties. Carbon nanotube synthesis primarily uses chemical vapor deposition (CVD) or arc discharge methods, which remain complex and costly, limiting scalability compared to carbon fiber. Scaling carbon nanotube production faces challenges in uniformity and alignment control, restricting their widespread industrial adoption relative to carbon fiber composites.

Applications in Industry: Carbon Fiber vs Carbon Nanotubes

Carbon fiber is extensively used in aerospace, automotive, and sporting goods industries due to its high strength-to-weight ratio and excellent durability, making it ideal for structural components and lightweight materials. Carbon nanotubes, with superior electrical conductivity and extraordinary tensile strength at the nanoscale, find critical applications in electronics, energy storage, and advanced composites for enhancing mechanical and electrical properties. While carbon fiber dominates large-scale structural uses, carbon nanotubes offer breakthroughs in nanotechnology-driven fields requiring enhanced performance at micro and nano levels.

Cost Analysis and Commercial Availability

Carbon fiber offers a more cost-effective solution with mature manufacturing processes enabling widespread commercial availability in automotive, aerospace, and sporting goods industries. Carbon nanotubes, despite superior strength-to-weight ratios and electrical properties, remain significantly more expensive due to complex synthesis and limited large-scale production. The higher cost and production challenges of carbon nanotubes restrict their commercial use mainly to niche applications like advanced electronics and high-performance composites.

Environmental Impact and Sustainability

Carbon fiber offers high strength-to-weight ratio with moderate environmental impact due to energy-intensive production and limited recyclability. Carbon nanotubes present potential for greener applications through enhanced material efficiency and lower usage amounts but currently face challenges in scalable, eco-friendly manufacturing processes. Advances in recycling technologies and sustainable synthesis methods remain critical for reducing the overall carbon footprint of both materials.

Future Trends in Carbon Material Innovations

Carbon fiber and carbon nanotubes represent pivotal advancements in carbon material technologies, with carbon nanotubes offering superior tensile strength, electrical conductivity, and thermal properties due to their nanoscale structure. Future trends emphasize hybrid composites combining carbon fiber's structural advantages with carbon nanotubes' enhanced mechanical and electrical performance for aerospace, automotive, and energy storage applications. Emerging research focuses on scalable manufacturing techniques and cost reduction to accelerate the adoption of these advanced carbon materials in next-generation high-performance products.

Carbon fiber vs Carbon nanotubes Infographic

materialdif.com

materialdif.com