Thermal carbonization involves the high-temperature treatment of organic materials in an inert atmosphere, resulting in carbon-rich solids with enhanced structural stability and porosity. Chemical vapor deposition (CVD) creates carbon coatings by decomposing gaseous hydrocarbons on substrates, enabling precise control over film thickness and morphology. While thermal carbonization produces bulk carbon materials with uniform properties, CVD offers superior tunability for thin films and nanostructures.

Table of Comparison

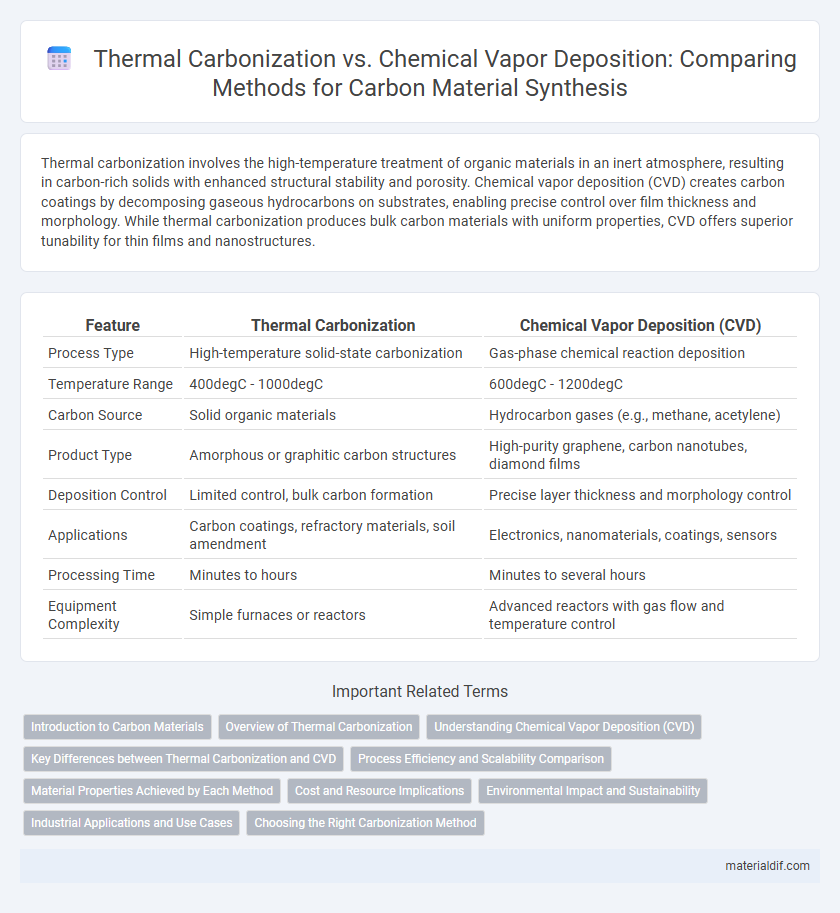

| Feature | Thermal Carbonization | Chemical Vapor Deposition (CVD) |

|---|---|---|

| Process Type | High-temperature solid-state carbonization | Gas-phase chemical reaction deposition |

| Temperature Range | 400degC - 1000degC | 600degC - 1200degC |

| Carbon Source | Solid organic materials | Hydrocarbon gases (e.g., methane, acetylene) |

| Product Type | Amorphous or graphitic carbon structures | High-purity graphene, carbon nanotubes, diamond films |

| Deposition Control | Limited control, bulk carbon formation | Precise layer thickness and morphology control |

| Applications | Carbon coatings, refractory materials, soil amendment | Electronics, nanomaterials, coatings, sensors |

| Processing Time | Minutes to hours | Minutes to several hours |

| Equipment Complexity | Simple furnaces or reactors | Advanced reactors with gas flow and temperature control |

Introduction to Carbon Materials

Thermal carbonization and chemical vapor deposition (CVD) are key techniques in synthesizing carbon materials with distinct structures and properties. Thermal carbonization involves heating carbon-rich precursors in an inert atmosphere to produce carbon with high thermal stability and tunable porosity. Chemical vapor deposition enables the growth of high-purity graphene, carbon nanotubes, and diamond-like carbon films by decomposing gaseous hydrocarbons on substrates, optimizing material quality for electronic and energy applications.

Overview of Thermal Carbonization

Thermal carbonization is a high-temperature process that converts organic materials into carbon-rich solids by heating in an inert atmosphere, typically between 600degC and 1200degC. This method enhances the material's porosity, thermal stability, and electrical conductivity, making it ideal for applications in energy storage and catalysis. Compared to chemical vapor deposition, thermal carbonization offers a simpler setup with fewer chemical precursors, focusing on bulk carbon production rather than thin film growth.

Understanding Chemical Vapor Deposition (CVD)

Chemical Vapor Deposition (CVD) is a technique used to produce high-purity, high-performance solid materials by depositing a thin film from a gas phase onto a substrate through chemical reactions. Unlike Thermal Carbonization, which involves heat treatment of organic materials to convert them into carbon, CVD allows precise control over the chemical composition and thickness of the deposited carbon layers. This method is central in fabricating carbon-based nanomaterials such as graphene and carbon nanotubes due to its scalability and versatility in industrial applications.

Key Differences between Thermal Carbonization and CVD

Thermal carbonization involves the decomposition of organic materials at high temperatures in an inert atmosphere, producing a carbon-rich solid with a porous structure ideal for energy storage and catalysis applications. Chemical Vapor Deposition (CVD) is a process where gaseous precursors react on a substrate surface at elevated temperatures, enabling the controlled growth of thin carbon films or nanotubes with high purity and uniformity. The key differences lie in thermal carbonization's bulk carbonization approach and material porosity versus CVD's surface-driven film deposition with precise structural control.

Process Efficiency and Scalability Comparison

Thermal carbonization offers high process efficiency through direct heat application, resulting in rapid carbon formation, while chemical vapor deposition (CVD) provides precise control over carbon structure but requires longer processing times and complex setups. Scalability favors thermal carbonization as it can be implemented in larger batch sizes with simpler equipment, whereas CVD's intricate gas-phase reactions and high vacuum conditions limit throughput and increase operational costs. Selecting between the two methods depends on balancing the need for uniform carbon quality versus industrial-scale production efficiency.

Material Properties Achieved by Each Method

Thermal carbonization produces carbon materials with high structural uniformity and excellent thermal stability by decomposing organic precursors at elevated temperatures in an inert atmosphere. Chemical vapor deposition (CVD) enables precise control over carbon layer thickness and crystallinity, resulting in graphene and carbon nanotubes with superior electrical conductivity and mechanical strength. Each method tailors carbon microstructure distinctly, with thermal carbonization favoring porous, amorphous carbons and CVD yielding highly ordered, crystalline films.

Cost and Resource Implications

Thermal carbonization offers a cost-effective and energy-efficient method by utilizing biomass waste with lower operational expenses compared to Chemical Vapor Deposition (CVD), which requires high-purity gases and expensive equipment. CVD provides superior material quality and precise carbon structure control but incurs significant resource consumption and higher production costs. Resource implications favor thermal carbonization for scalability and sustainability, while CVD suits advanced applications demanding premium carbon materials despite its resource intensity.

Environmental Impact and Sustainability

Thermal carbonization produces carbon materials by heating biomass in an oxygen-limited environment, resulting in lower greenhouse gas emissions and enhanced carbon sequestration compared to traditional methods. Chemical vapor deposition (CVD) involves high energy consumption and the use of hazardous gases, raising concerns about air pollution and resource depletion. Sustainable carbon production prioritizes thermal carbonization for its reduced environmental footprint and renewable feedstock utilization.

Industrial Applications and Use Cases

Thermal carbonization and chemical vapor deposition (CVD) both play crucial roles in industrial carbon production, with thermal carbonization primarily used for converting biomass into biochar and activated carbon for soil amendment and pollutant adsorption. Chemical vapor deposition is extensively applied in semiconductor manufacturing and advanced material coatings, enabling production of high-purity graphene, carbon nanotubes, and diamond-like carbon films for electronics, aerospace, and energy storage. These methods differ in scalability and material properties, making thermal carbonization ideal for bulk carbon materials and CVD suitable for precision engineering and nanomaterial fabrication.

Choosing the Right Carbonization Method

Thermal carbonization and chemical vapor deposition (CVD) offer distinct advantages based on the desired carbon structure and application. Thermal carbonization is ideal for bulk carbon materials with high thermal stability and uniformity, while CVD excels in producing thin carbon films and nanostructures with precise control over thickness and composition. Selecting the right carbonization method depends on factors such as temperature range, substrate compatibility, and the required carbon morphology for advanced energy storage or sensor technologies.

Thermal Carbonization vs Chemical Vapor Deposition Infographic

materialdif.com

materialdif.com