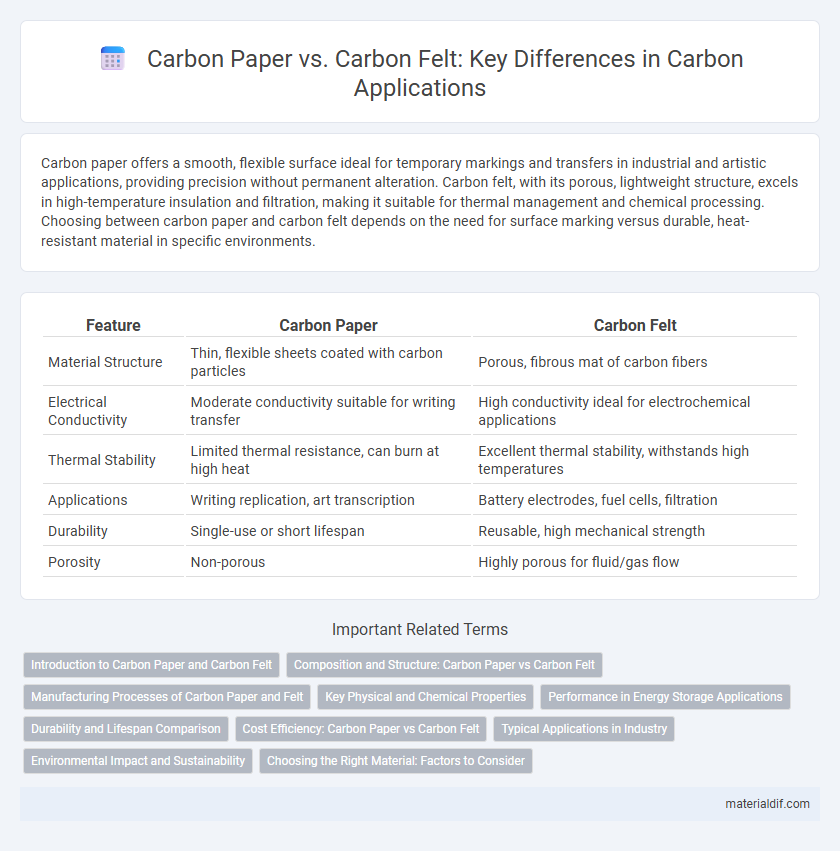

Carbon paper offers a smooth, flexible surface ideal for temporary markings and transfers in industrial and artistic applications, providing precision without permanent alteration. Carbon felt, with its porous, lightweight structure, excels in high-temperature insulation and filtration, making it suitable for thermal management and chemical processing. Choosing between carbon paper and carbon felt depends on the need for surface marking versus durable, heat-resistant material in specific environments.

Table of Comparison

| Feature | Carbon Paper | Carbon Felt |

|---|---|---|

| Material Structure | Thin, flexible sheets coated with carbon particles | Porous, fibrous mat of carbon fibers |

| Electrical Conductivity | Moderate conductivity suitable for writing transfer | High conductivity ideal for electrochemical applications |

| Thermal Stability | Limited thermal resistance, can burn at high heat | Excellent thermal stability, withstands high temperatures |

| Applications | Writing replication, art transcription | Battery electrodes, fuel cells, filtration |

| Durability | Single-use or short lifespan | Reusable, high mechanical strength |

| Porosity | Non-porous | Highly porous for fluid/gas flow |

Introduction to Carbon Paper and Carbon Felt

Carbon paper consists of thin sheets coated with a layer of pigmented carbon, primarily used for transferring written or printed text through pressure. Carbon felt is a porous, non-woven material made from carbon fibers, known for its high surface area and excellent conductivity, often utilized in filtration and electrochemical applications. Both materials leverage carbon's unique properties but differ significantly in structure and functional uses.

Composition and Structure: Carbon Paper vs Carbon Felt

Carbon paper consists of thin sheets of carbon-coated paper designed for transferring ink impressions, featuring a smooth, dense surface optimized for sharp printing. Carbon felt is a porous, fibrous material composed of entangled carbon fibers, offering high surface area and excellent permeability for filtration or electrode applications. The structural difference lies in the compact, layered arrangement of carbon paper versus the open, three-dimensional matrix of carbon felt, influencing their performance in conductivity and mechanical flexibility.

Manufacturing Processes of Carbon Paper and Felt

Carbon paper manufacturing involves pressing and saturating tissue or fabric with a carbon-based ink or pigment to create a thin, flexible sheet used for transfer or marking purposes. In contrast, carbon felt production requires the entanglement and bonding of carbon fibers through heat treatment and chemical processes, resulting in a porous, high-strength material designed for thermal insulation and filtration applications. The manufacturing of carbon felt emphasizes fiber orientation and density control, whereas carbon paper focuses on uniform ink distribution and surface smoothness.

Key Physical and Chemical Properties

Carbon paper exhibits high electrical conductivity and excellent thermal stability but has limited porosity and mechanical flexibility. Carbon felt features a highly porous structure, superior surface area, and enhanced chemical inertness, making it ideal for filtration and electrochemical applications. Both materials possess strong carbon-carbon bonds, but carbon felt's fibrous morphology provides greater durability and reactive surface sites compared to the dense, laminated form of carbon paper.

Performance in Energy Storage Applications

Carbon felt offers superior electrochemical performance in energy storage applications due to its high porosity, large surface area, and excellent conductivity compared to carbon paper. Its 3D fibrous structure enhances ion diffusion and electron transfer, leading to improved charge-discharge efficiency and higher power density in devices like flow batteries and supercapacitors. Carbon paper, while providing good mechanical strength and lower cost, often exhibits limited surface area and reduced catalytic activity, impacting overall cell performance.

Durability and Lifespan Comparison

Carbon felt offers superior durability and a longer lifespan compared to carbon paper due to its fibrous structure, which provides enhanced mechanical strength and resistance to wear. Carbon paper, while effective for temporary applications, tends to degrade faster under high temperatures and prolonged use, limiting its lifespan. The porous nature of carbon felt allows for better thermal stability and chemical resistance, making it a preferred choice in industrial processes requiring longevity.

Cost Efficiency: Carbon Paper vs Carbon Felt

Carbon paper offers higher cost efficiency due to its lower initial price and ease of production, making it suitable for short-term and disposable applications. Carbon felt, while more expensive upfront, provides superior durability and thermal stability, resulting in lower replacement frequency and improved long-term cost savings. The choice between carbon paper and carbon felt ultimately depends on balancing immediate budget constraints with durability requirements in specific industrial uses.

Typical Applications in Industry

Carbon paper is widely utilized in printing, art reproduction, and temporary markings due to its ability to transfer ink or carbon-based materials onto surfaces accurately. Carbon felt finds extensive application in high-temperature industrial settings such as thermal insulation in furnaces, electrode materials in electrochemical cells, and filtration systems because of its porous structure and thermal stability. Each material's unique properties dictate its use: carbon paper excels in precise ink transfer processes, while carbon felt is preferred for durability and heat resistance in demanding technical environments.

Environmental Impact and Sustainability

Carbon felt demonstrates a more sustainable profile compared to carbon paper due to its higher durability and reusability, which reduces waste generation. Carbon paper, typically single-use and composed of non-recyclable materials, contributes significantly to landfill accumulation and environmental pollution. Manufacturing processes of carbon felt often involve lower energy consumption and less chemical usage, enhancing its eco-friendly attributes over carbon paper.

Choosing the Right Material: Factors to Consider

Carbon paper offers precise, consistent marking ideal for duplicating tasks, while carbon felt provides superior thermal insulation and flexibility for industrial applications. Selecting the right material depends on factors such as required conductivity, temperature resistance, mechanical durability, and application-specific performance needs. Evaluating these criteria ensures optimal functionality in processes ranging from printing to electrochemical systems.

Carbon Paper vs Carbon Felt Infographic

materialdif.com

materialdif.com